Belt

A technology for seat belts and weft yarns, applied in the belt field, can solve the problems of risk of damage and suboptimal width in the width direction, and achieve the effect of high elongation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

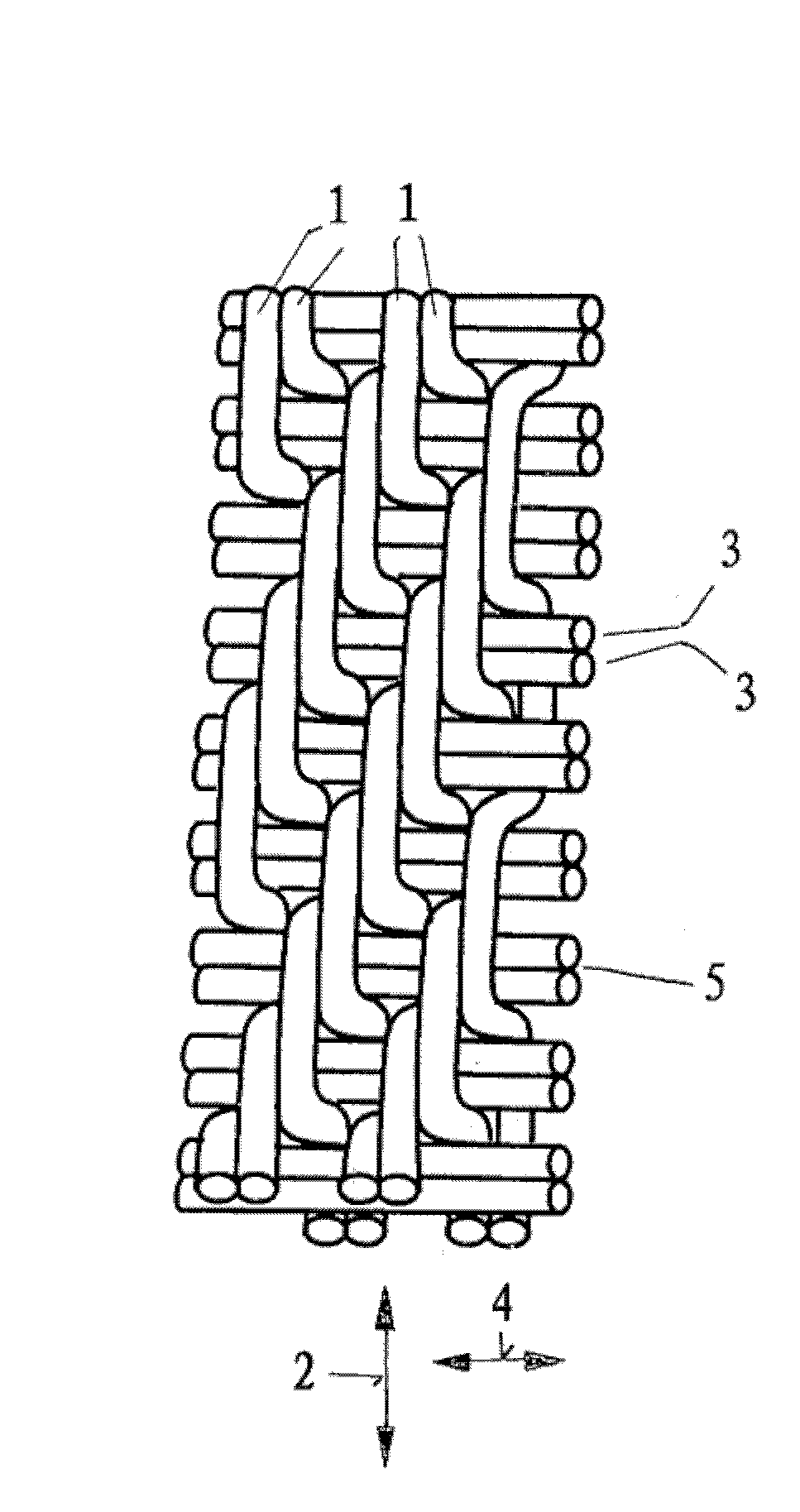

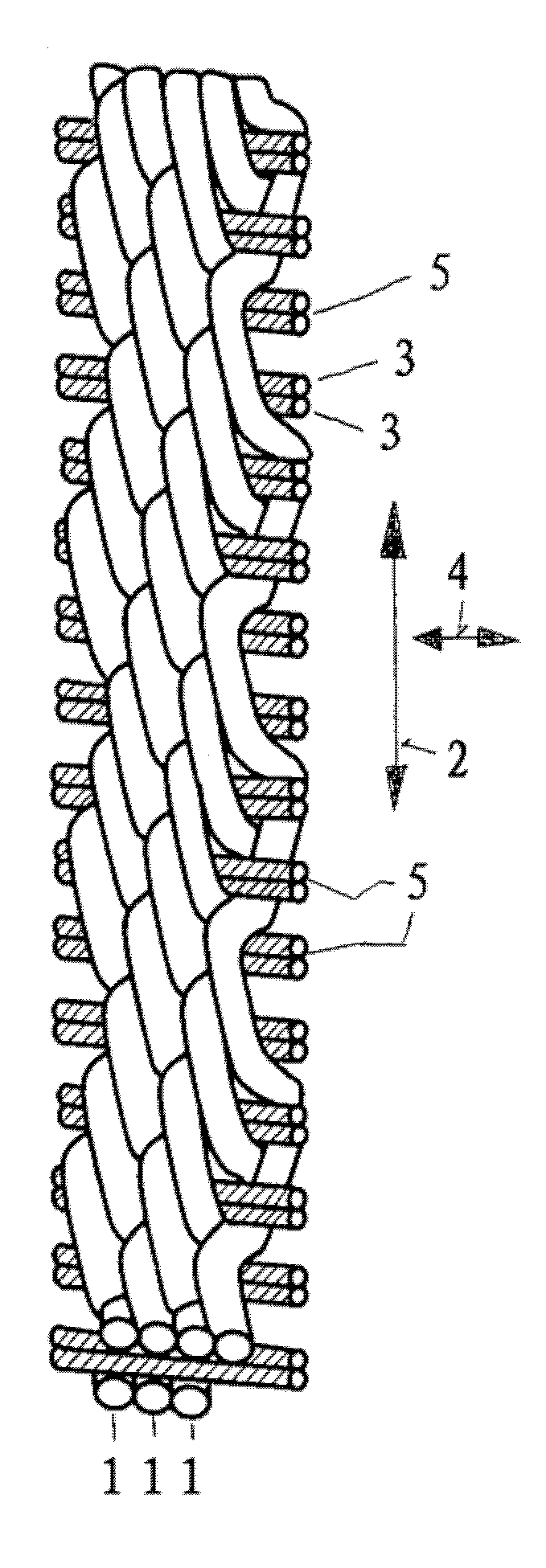

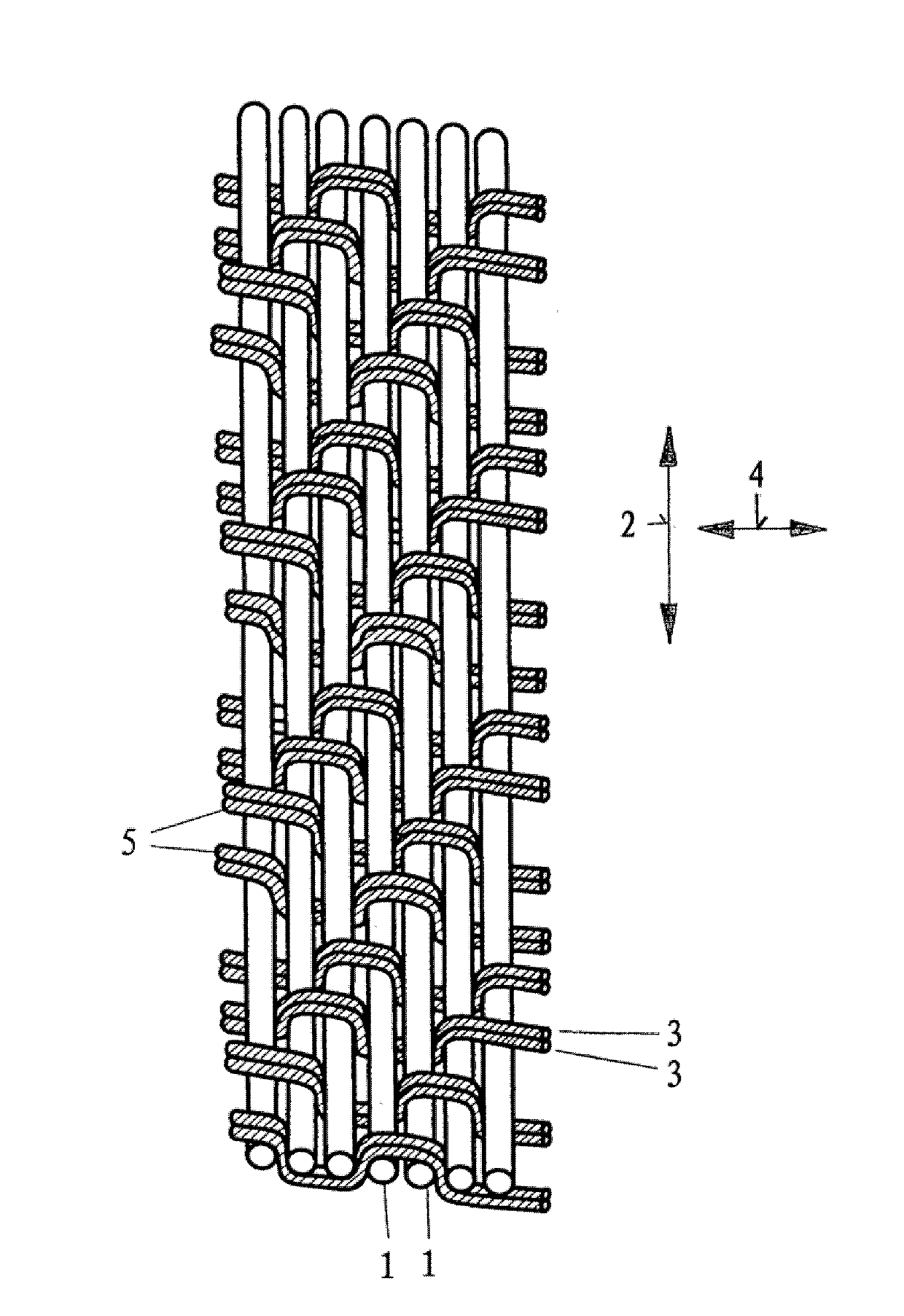

[0016] according to figure 1 The tape fabric of FIG. 2 shows the weave pattern between warp threads 1 running in the longitudinal direction 2 of the tape and weft threads 3 running transversely to the warp threads 1 . It can be seen that the weft threads 3 are each present in a double arrangement 5 , whereas the warp threads 1 are always wound around two such successive arrangements 5 . It can also be seen that the successive warp threads 1 along the transverse direction 4 are each offset by one such arrangement along the longitudinal direction 2 .

[0017] Just to illustrate the fabric structure, figure 1 In particular, an arrangement of the warp threads 1 separated by a wide distance from one another is shown. while in figure 2 In the actual product shown, the warp threads 1 lie closely against one another, wherein the warp threads 1 lying sideways against one another form a unique surface structure due to the offset arrangement in the longitudinal direction 2 .

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com