High-voltage power transmission line ice-covering-proof paint and preparation method thereof

A high-voltage transmission line, anti-icing technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of poor anti-icing, cracking and powder coating, no thermal conductivity, etc., and achieve excellent water resistance and aging resistance. , strong adhesion, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

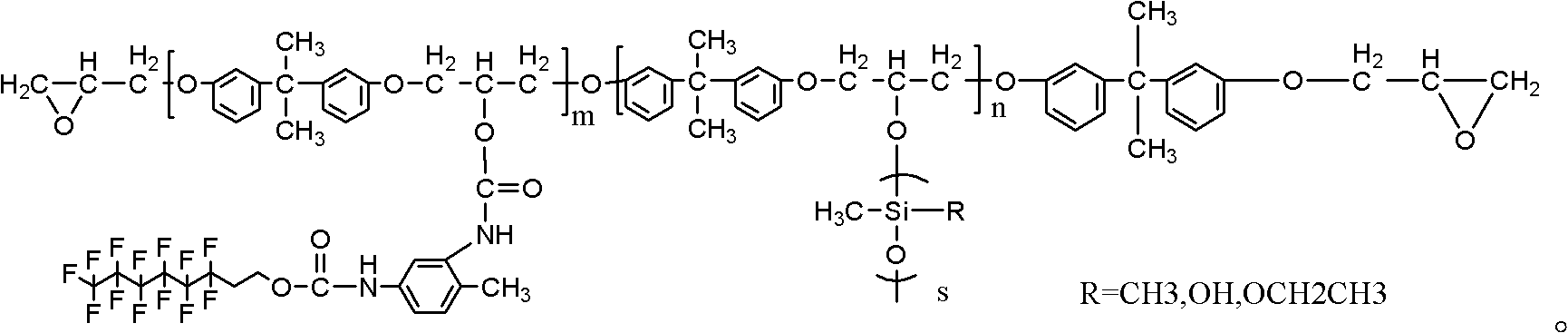

Method used

Image

Examples

Embodiment 1

[0028] Take 15-30 grams of acetone, 5-15 grams of n-butanol, and 300-450 grams of butyl acetate, and mix and stir evenly at room temperature to prepare a mixed organic solvent.

Embodiment 2

[0030] Take 15-25 grams of expanded graphite and 100-150 grams of butyl acetate, mix and stir evenly, and treat under ultrasonic waves with a power of 100W for 24-48 hours to obtain nano-graphite.

Embodiment 3

[0032] Take 55-75 grams of toluene diisocyanate, add it into the reaction kettle, raise the temperature to 55-65 ° C, add 150-182 grams of tridecafluorooctyl alcohol dropwise under stirring, the rotation speed is 350-460 rpm, add dropwise After completion, the reactor was heated to 85°C to continue the reaction for 2 hours

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com