Ultraviolet light solidifying paint containing POSS and its preparation method

A technology for curing coatings and ultraviolet light, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of rare POSS applications, and achieve the effects of great development prospects, low pollution, and fast curing of coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

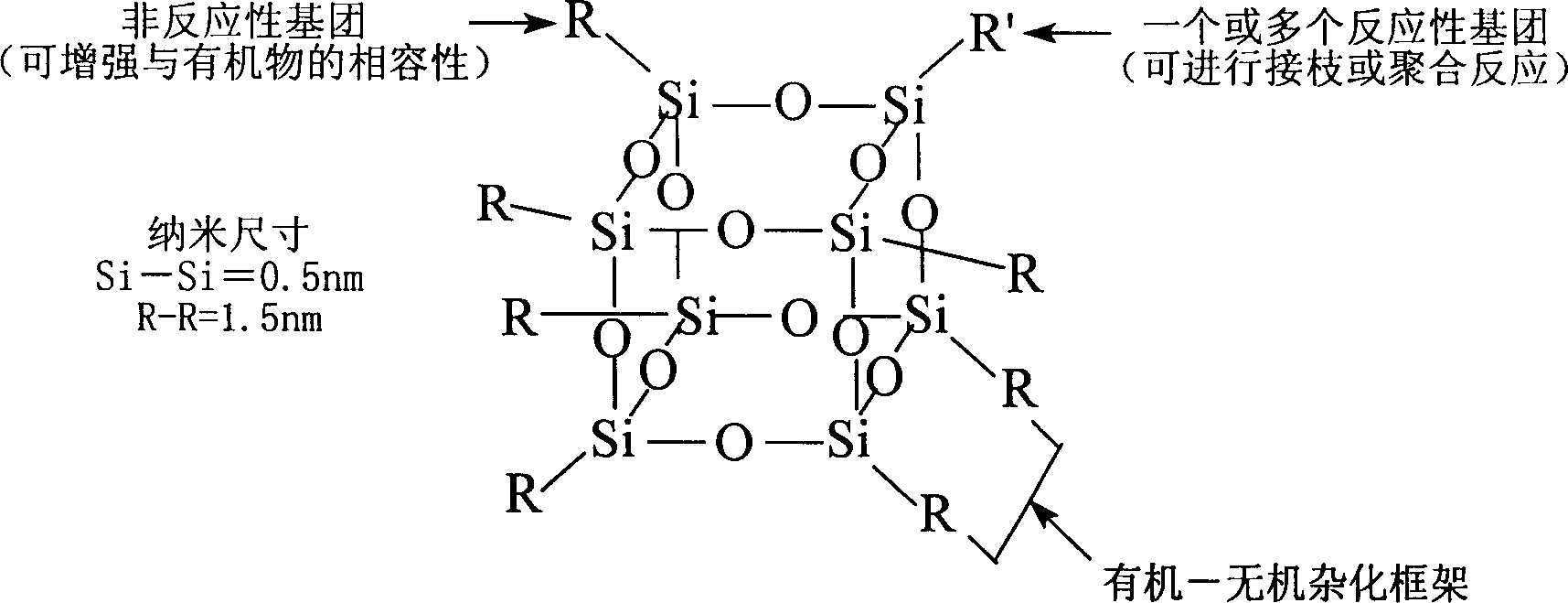

Method used

Image

Examples

Embodiment 1

[0044] In a three-necked flask equipped with a reflux condensing device and a stirrer, carefully add 17.7 mL of distilled water to 10 mL of trichloromethylsiloxane and 60 mL of acetone under stirring conditions, and stir in a water bath at 50 ° C for 48 hours, and the reaction is completed Afterwards, the collected white solid was washed with acetone and filtered, and then vacuum-dried overnight at 45 ° C. The product was suspended with 20 times the weight of pyridine and stirred overnight, and the pyridine solution was poured into a mixture of an equal volume of concentrated hydrochloric acid and ice, and then The collected precipitate was washed with water until neutral, and dried under vacuum at 60° C. overnight. And then thoroughly extracted with ether, unmodified POSS can be obtained. Then in the mixed solution of triethylamine / tetrahydrofuran (1:100, volume ratio) of the above-mentioned POSS with a concentration of 15ml of 0.025g / ml, 20ml of a concentration of 0.025g / ml ...

Embodiment 2

[0047] The same preparation conditions as in Example 1 were adopted, but the amount of POSS containing a double bond was changed to 1.0 g. The prepared polyurethane acrylate UV-curable coating containing POSS is sample 2 (containing 5% POSS).

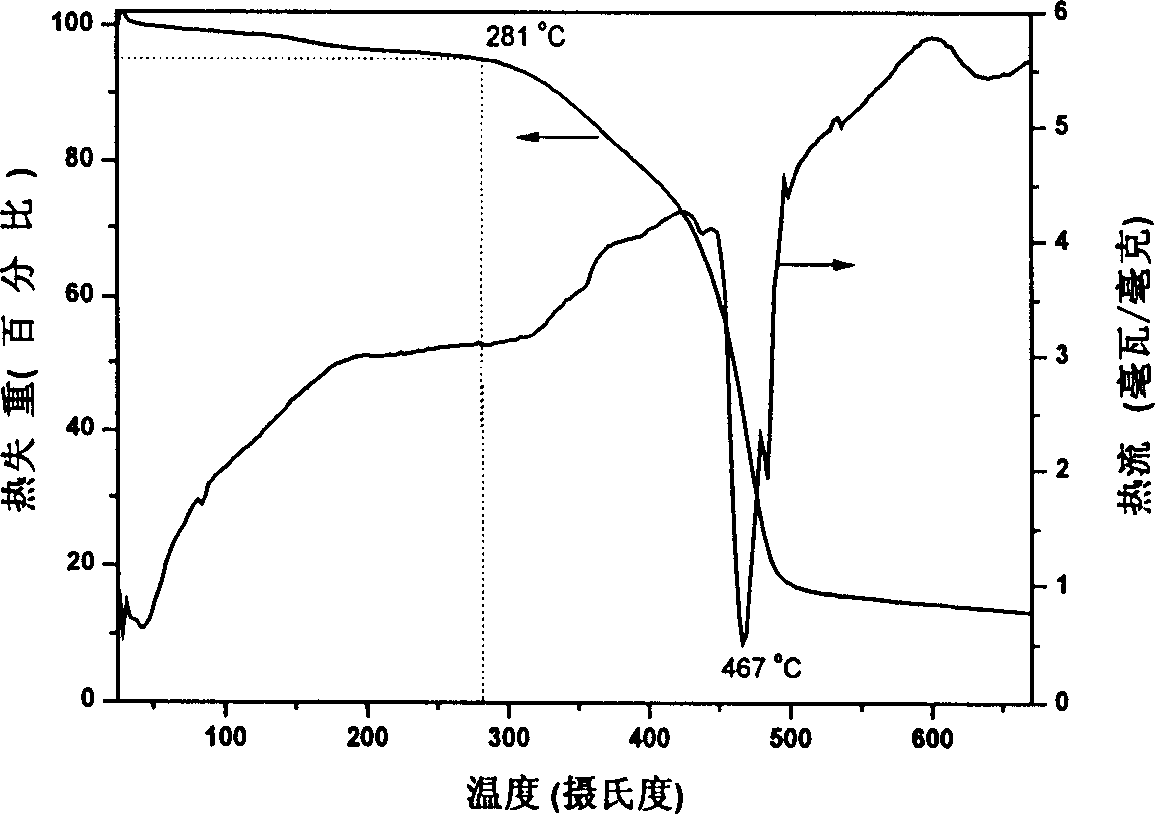

[0048] Figure 4 is the TG-DSC curve (containing 5% POSS) of this polyurethane acrylate UV-curable coating film containing POSS. The performance results of the POSS-containing polyurethane acrylate UV-curable coating film are shown in Table 1.

Embodiment 3

[0050] The same preparation conditions as in Example 1 were used, but the diluent butyl acrylate (10 g) was changed to butyl acrylate (5.0 g) and trimethylolpropane triacrylate (TMPTA) (5.0 g). The prepared polyurethane acrylate UV-curable coating containing POSS is sample 3.

[0051] The performance results of the POSS-containing polyurethane acrylate UV-curable coating film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com