Graphene oxide modified aqueous acrylic acid functional coating and preparation method thereof

A water-based acrylic and graphene modification technology, applied in the direction of anti-corrosion coatings, etc., can solve the problems that water-based acrylic coatings cannot achieve corrosion resistance, and achieve the effect of improving anti-corrosion performance and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of functionalized graphene dispersion:

[0032] 1) Weigh a certain amount of graphene oxide, add it to a beaker, and then add an appropriate amount of distilled water to prepare a graphene oxide aqueous dispersion with a concentration of 0.05g / ml, and then ultrasonically disperse the graphene oxide aqueous dispersion for 60 minutes;

[0033] 2) Weigh 40ml of graphene oxide aqueous dispersion and heat it to 60°C, add 30ml of polyethylene glycol dropwise to the graphene oxide aqueous dispersion, stir and react for 2 hours while maintaining a constant temperature of 60°C to obtain functionalized graphene dispersion liquid.

[0034] 2. Preparation of water-based acrylic emulsion:

[0035] 1) Add 10g of water, 2g of emulsifier (sodium lauryl sulfate), 25g of butyl acrylate, 5g of methacrylamide, 5g of vinyl acetate and 5g of styrene into the reaction vessel and stir for 30min to obtain a stable pre-emulsion ;

[0036] 2) Add 20g of water and 1g of emulsifie...

Embodiment 2

[0045] Embodiment two: adopt the method step and proportioning that are basically the same as embodiment one, the difference between the two is: in the step S1 of preparing graphene oxide modified water-based acrylic functional coating, the functionalized graphene dispersion liquid of 10ml is Add it dropwise to 50ml of water-based acrylic emulsion, and stir at a speed of 1000-1500rpm for 10-20min to disperse it evenly to obtain a PEG-GO / acrylic emulsion mixture.

Embodiment 3

[0046] Embodiment three: adopt the method step and proportioning that are basically the same as embodiment one, the difference between the two is: in the step S1 of preparing graphene oxide modified water-based acrylic functional coating, the functionalized graphene dispersion liquid of 15ml is Add it dropwise to 50ml of water-based acrylic emulsion, and stir at a speed of 1000-1500rpm for 10-20min to disperse it evenly to obtain a PEG-GO / acrylic emulsion mixture.

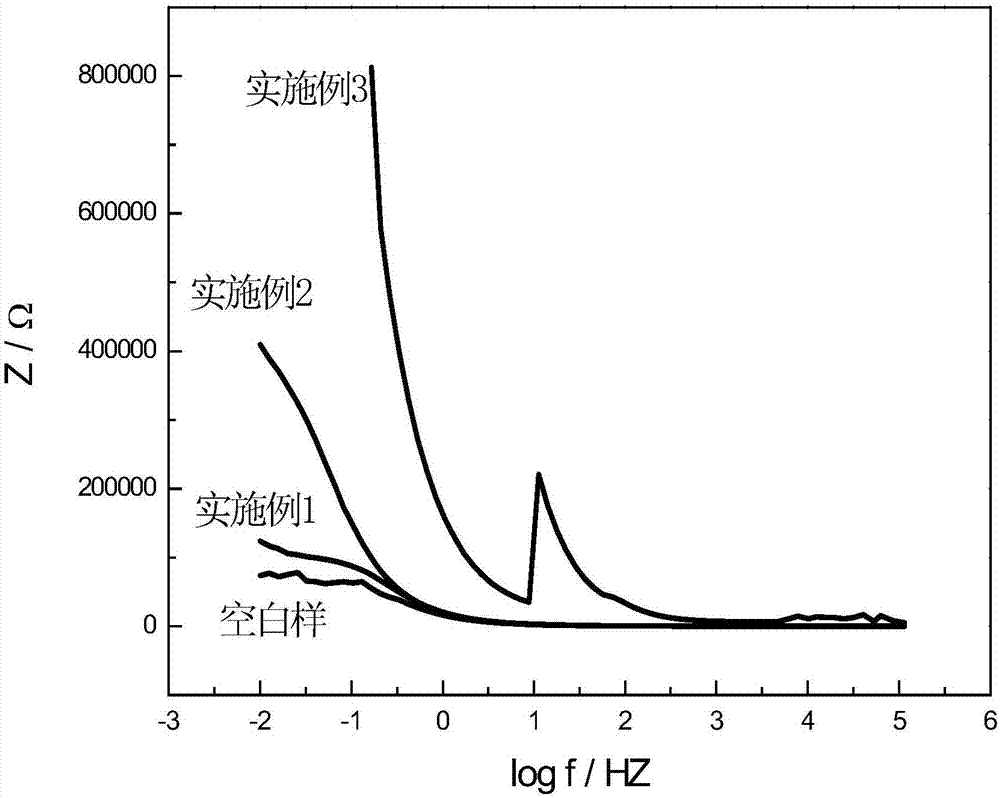

[0047]Utilize the electrochemical AC impedance test results of the coating to evaluate the anticorrosion properties of the coating films of Examples 1 to 3: first, dry the prepared coating, soak it in 3.5% NaCl solution for 24h, and carry out the AC impedance test , the obtained AC impedance data is fitted with the ZView impedance analysis software; finally, the measured data is drawn into a graph (ie: Bode graph) with the origin software. In the Bode graph, the impedance of the coating in the high-frequency region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com