High thermal-sealing type acrylic coating special for cigarette film and preparation method thereof

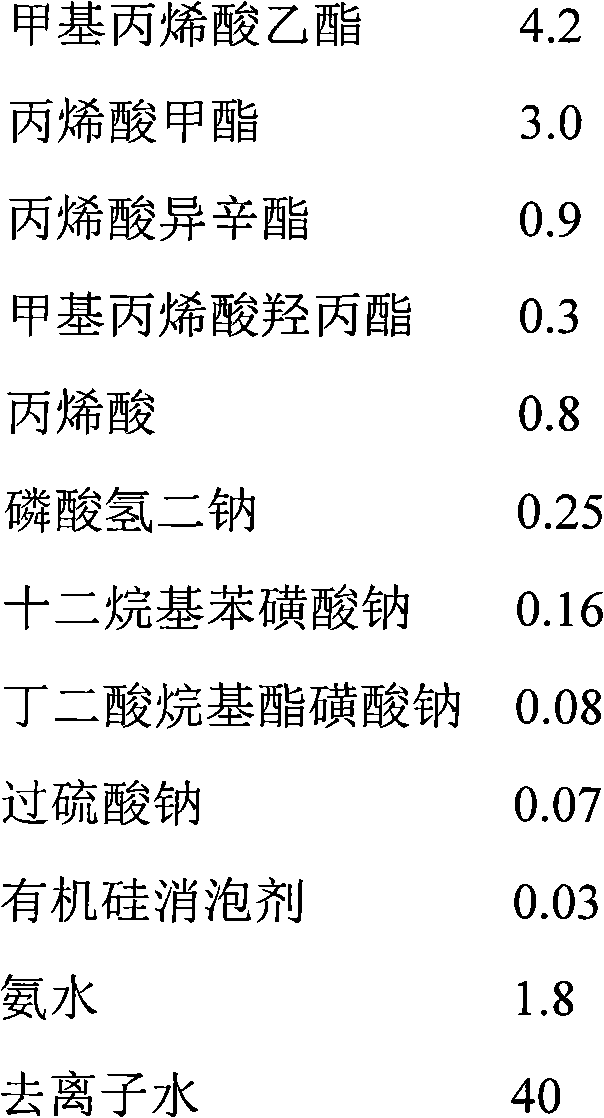

A technology of acrylic acid and acrylic acid ester, applied in the direction of coating, can solve the problem of heat sealing performance, printing performance can not reach the paperless carton strip packaging film and other problems, achieve good compatibility of general additives, stable polymerization system, easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

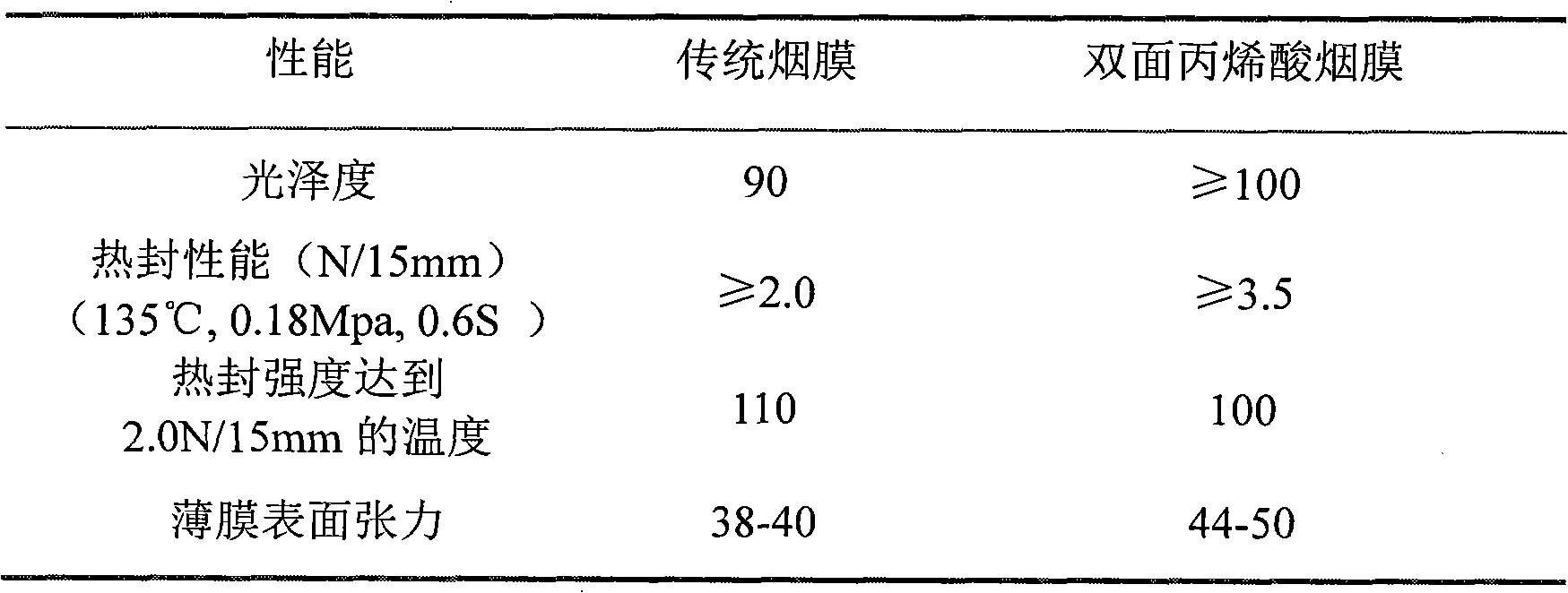

[0022] Prepare raw materials according to the following components (unit: kg)

[0023]

[0024] Synthetic method: First, mix 0.02kg sodium dodecylbenzenesulfonate and 0.01kg sodium alkyl succinate sulfonate with all monomers and stir for 40 minutes, and control the stirring speed at 200 rpm to obtain pre-emulsion A; 0.03 Dissolve kg of potassium persulfate with 1 kg of deionized water to form solution B. Add 5% pre-emulsion A, 25% solution B and 8kg deionized water into the reactor, control the stirring speed at 160 rpm, raise the temperature to 82°C and react for about 0.5 hours to obtain the seed emulsion. Start to add the remaining pre-emulsion A and the remaining solution B dropwise, and finish dropping in 2.5 hours, and control the pre-emulsion A to finish dropping first. Keep the reaction at 86°C for 2 hours, lower the temperature to 65°C, increase the stirring speed to 250 rpm, add 0.3kg of ammonia water to adjust the pH value to 9.2, add 0.02kg of silicone defoamer...

Embodiment 2

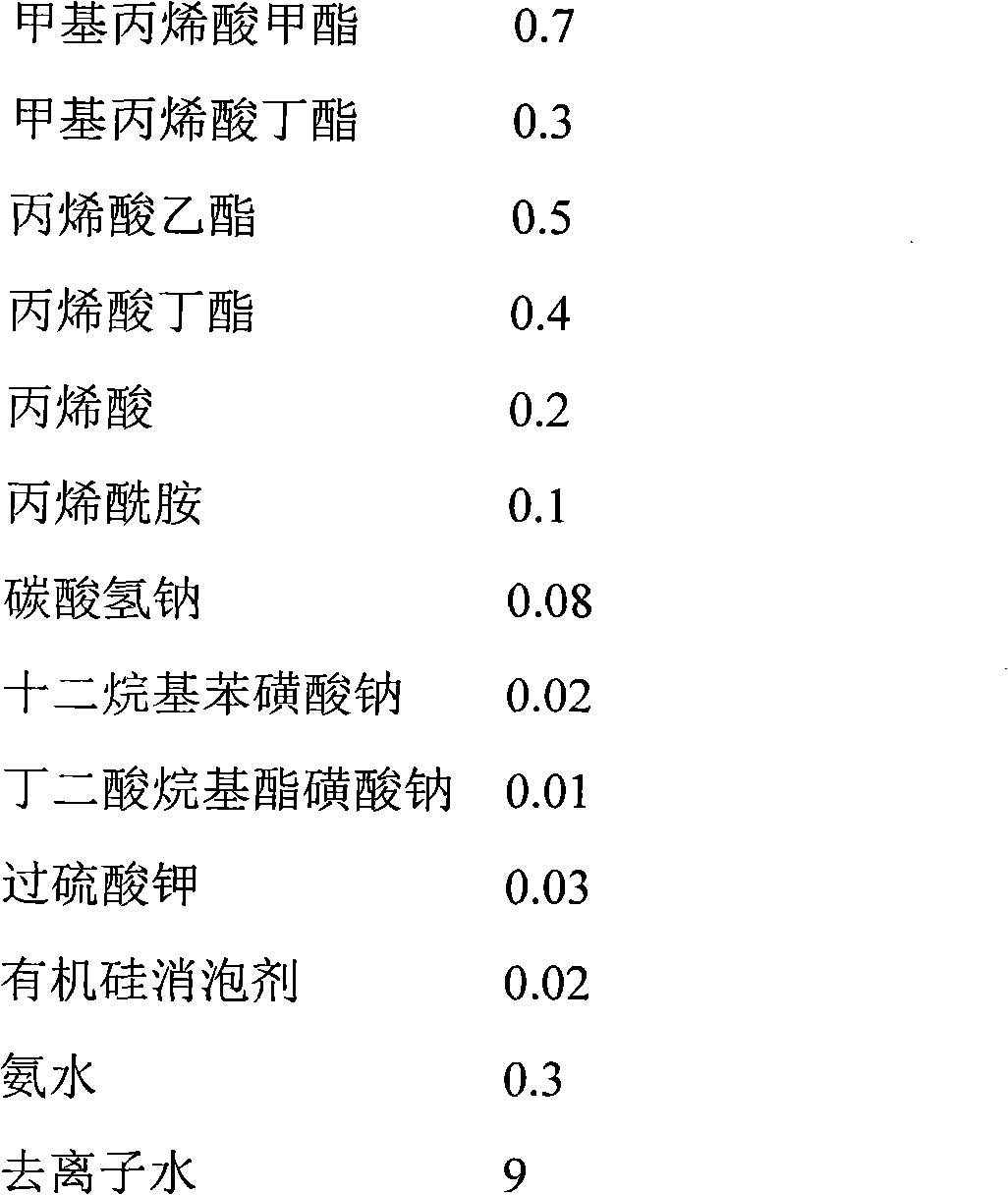

[0026] Prepare raw materials according to the following components (unit: kg)

[0027]

[0028] Synthetic method: First, mix 0.16 kg sodium dodecylbenzene sulfonate and 0.08 kg sodium alkyl succinate sulfonate with all monomers and stir for 0.5 hours, and the stirring speed is controlled at 210 rpm to obtain pre-emulsion A; 0.07 Dissolve kg of sodium persulfate with 6 kg of deionized water to form solution B. Add 10% pre-emulsion A, 10% solution B, 0.25kg disodium hydrogen phosphate and 34kg deionized water into the reactor, control the stirring speed at 165 rpm, raise the temperature to 80°C and react for about 40 minutes to obtain the seed emulsion . Start to add the remaining pre-emulsion A and the remaining solution B dropwise, and finish dropping in 3 hours, and control the pre-emulsion A to finish dropping first. Keep the reaction at 85°C for 1.5 hours, lower the temperature to 60°C, increase the stirring speed to 230 rpm, add 1.8kg of ammonia water to adjust the pH...

Embodiment 3

[0030] Prepare raw materials according to the following components (unit: kg)

[0031]

[0032]

[0033] Synthetic method: First, mix 0.08kg sodium dodecylbenzenesulfonate and 0.02kg sodium alkyl succinate sulfonate with all monomers and stir for 1 hour, and the stirring speed is controlled at 200 rpm to obtain pre-emulsion A; 0.08 Dissolve kg of ammonium persulfate with 3 kg of deionized water to form solution B. Add 5% pre-emulsion A, 30% solution B, 0.13kg sodium bicarbonate and 18kg deionized water into the reactor, control the stirring speed at 160 rpm, raise the temperature to 85°C and react for about 0.5 hours to obtain a seed emulsion. Start to drop the remaining pre-emulsion A and remaining solution B, and finish dropping within 3.5 hours, and control the pre-emulsion A to finish dropping first. Keep the reaction at 87°C for 1 hour, lower the temperature to below 70°C, increase the stirring speed to 220 rpm, add 0.8kg of ammonia water to adjust the pH value to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com