Organosilicon modified waterborne photo-curing epoxy-acrylic coating and preparation method thereof

A technology of epoxy propylene and silicone, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of water-based light-curing epoxy acrylate resins such as water resistance and poor mechanical properties, and achieve improved water resistance and hardness, Improve the effect of cross-linking points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

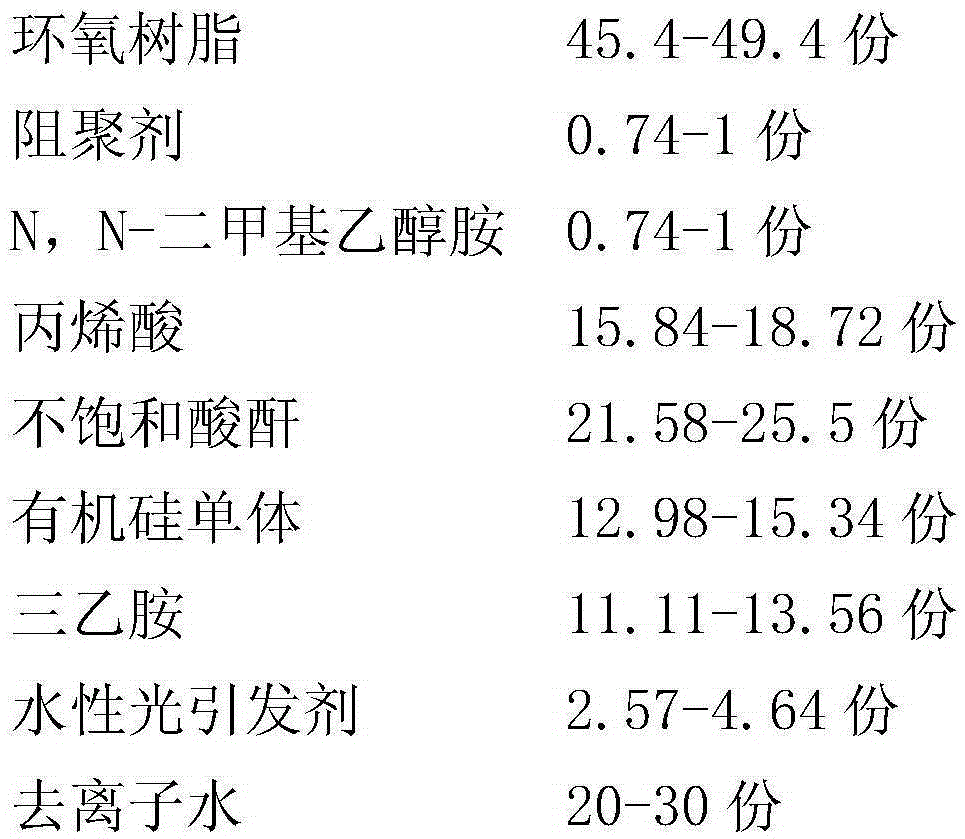

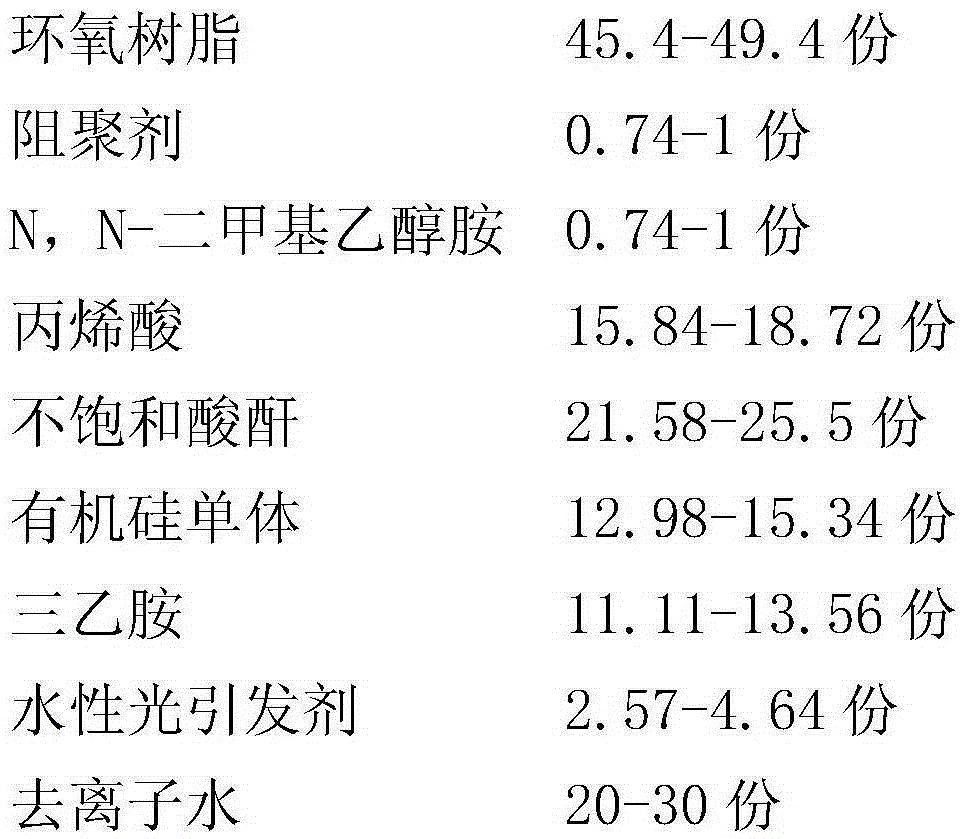

[0032] Components of Silicone Modified Waterborne Photocurable Epoxy-Acrylic Prepolymer

[0033]

[0034] 1) Preparation of epoxy propylene ester prepolymer:

[0035] In the reactor, at room temperature, add 45.4-49.4 parts of epoxy resin and 0.4-0.6 parts of polymerization inhibitor, then adjust the rotation speed to 200-350rmp, when the temperature rises to 75-85°C, then slowly add 15.84- 18.72 parts of acrylic acid and 0.4-0.6 parts of N, N-dimethylaniline, the time of dropping is 0.5-1h, after the dropping is completed, the temperature is raised to 86-90°C, and then the acid value is measured every half hour until the acid value When it is 3-5mgKOH / g, lower the temperature to obtain epoxy acrylic acid prepolymer;

[0036] 2) Preparation of unsaturated anhydride-modified epoxy propylene ester prepolymer:

[0037] When the temperature of the reaction system prepared in step 1) is lowered to 50-60°C, while maintaining the above speed, add 21.58-25.5 parts of unsaturated ...

Embodiment 1

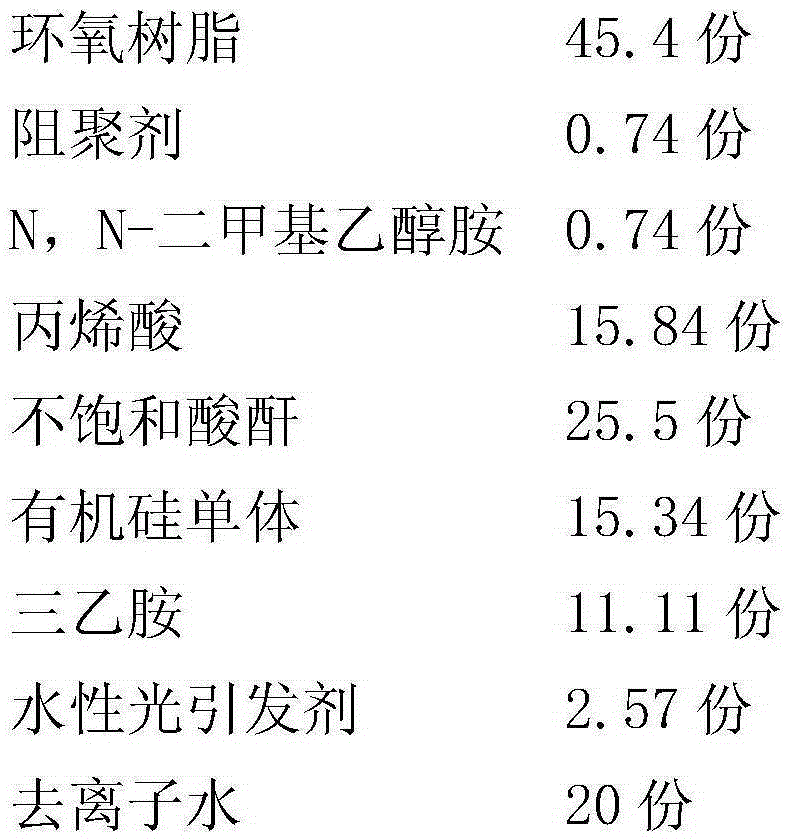

[0045] Components of Silicone Modified Waterborne Photocurable Epoxy-Acrylic Prepolymer

[0046]

[0047] 1) Preparation of epoxy propylene ester prepolymer:

[0048] equipped with stirrer, condenser, N 2 Add epoxy resin and 0.4 parts of polymerization inhibitor to the five-necked flask of the catheter, constant pressure funnel and thermometer, and the rotation speed is 200rmp. -Dimethylethanolamine, after 0.5h of dropwise addition, then the temperature was raised to 86°C, and the acid value was measured by sampling regularly, until the acid value was lower than 5mgKOH / g, the temperature was lowered to obtain the epoxy acrylic acid prepolymer.

[0049] 2) Preparation of unsaturated acid anhydride modified epoxy propylene ester prepolymer:

[0050] When the temperature of the above reaction system is lowered to 60°C, the rotation speed is 200rmp, add unsaturated acid anhydride, 0.34 parts of catalyst N,N-dimethylaniline and 0.34 parts of polymerization inhibitor, stir well...

Embodiment 2

[0056]

[0057] 1) Preparation of epoxy propylene ester prepolymer:

[0058] equipped with stirrer, condenser, N 2 Add epoxy resin and 0.55% polymerization inhibitor to the five-necked flask of conduit, constant pressure funnel and thermometer, and the rotation speed is 270rmp. Methylethanolamine, 0.5-1h dropwise is completed, then the temperature is raised to 85°C, and the acid value is measured by sampling regularly, until the acid value is lower than 5mgKOH / g, the temperature is lowered to obtain the epoxy acrylic acid prepolymer.

[0059] 2) Preparation of unsaturated acid anhydride modified epoxy propylene ester prepolymer:

[0060] When the temperature of the above reaction system is lowered to 60°C, the rotation speed is 270rmp, add unsaturated acid anhydride, 0.37% of catalyst N,N-dimethylaniline and 0.4 part of polymerization inhibitor, fully stir evenly, and control the temperature at 65°C. When the acid value reaches the theoretical value, the temperature is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com