Room temperature self-crosslinking acrylic emulsion and a preparation method thereof

A self-crosslinking acrylic and acrylic technology, used in applications, inks, household appliances, etc., can solve the problems of water resistance, poor alcohol dilution resistance, inability to produce chemical bonds, poor printing effect, etc., and achieve good adhesion and physical properties. Improved, dry film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

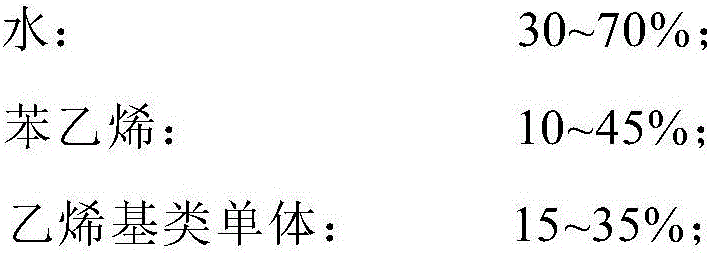

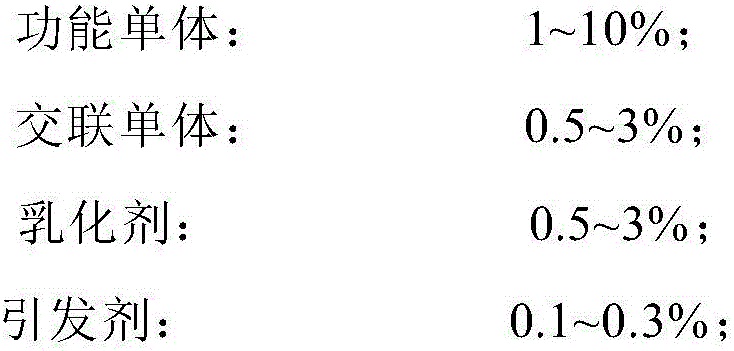

[0027] This embodiment relates to a kind of acrylic emulsion of this embodiment using the raw materials of the following components and contents for preparation:

[0028]

[0029]

[0030] Above-mentioned aqueous acrylic acid emulsion is prepared according to the following process steps:

[0031] Feeding: After rinsing the two reactors, add components B and C as the pre-emulsion according to the formula ratio, turn on the stirring at 800rpm to make it evenly stirred, then keep the speed at 250rpm, take out 5g of component B as the seed, and at the same time Add two 40% portions of Part D to the B and C pre-emulsions respectively. Use component A as the primer, raise the temperature to 80°C, add initiator 10% E to the primer, add the seed emulsion for 5 minutes and keep it warm for 30 minutes, start to add the pre-emulsion B component for about 1 hour, keep it warm for 1 hour, and then drop Add component C for about 1 hour, keep warm for 2 hours, then cool down to 40°C, ...

Embodiment 2

[0035] The acrylic emulsion of this embodiment is prepared using the raw materials of the following components and contents:

[0036]

[0037]

[0038] Above-mentioned aqueous acrylic acid emulsion is prepared according to the following process steps:

[0039] Feeding: After rinsing the two reactors, add components B and C as the pre-emulsion according to the formula ratio, turn on the stirring at 800rpm to make it evenly stirred, then keep the speed at 250rpm, take out 5g of component B as the seed, and at the same time Add two 40% portions of Part D to the B and C pre-emulsions respectively. Use component A as the primer, raise the temperature to 80°C, add initiator 10% E to the primer, add the seed emulsion for 5 minutes and keep it warm for 30 minutes, start to add the pre-emulsion B component for about 1 hour, keep it warm for 1 hour, and then drop Add component C for about 1 hour, keep warm for 2 hours, then cool down to 40°C, add F and stir for 20 minutes when th...

Embodiment 3

[0044] The acrylic emulsion of this embodiment is prepared using the raw materials of the following components and contents:

[0045]

[0046] Above-mentioned aqueous acrylic acid emulsion is prepared according to the following process steps:

[0047] Feeding: After rinsing the two reactors, add components B and C as the pre-emulsion according to the formula ratio, turn on the stirring at 800rpm to make it evenly stirred, then keep the speed at 250rpm, take out 5g of component B as the seed, and at the same time Add two parts of 40% component D to B and C pre-emulsion respectively. Use component A as the primer, raise the temperature to 80°C, add initiator 10% E to the primer, add the seed emulsion for 5 minutes and keep it warm for 30 minutes, start to add the pre-emulsion B component dropwise for about 1 hour, keep it warm for 1 hour, and then Add component C dropwise for about 1 hour, keep warm for 2 hours, then cool down to 40°C, add F and stir for 20 minutes when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com