Reflective radiation refrigeration film

A technology of radiation refrigeration and film, which is applied in refrigerators, refrigeration and liquefaction, and radiation-absorbing coatings. It can solve the problems of difficult control of the refrigeration film preparation process, complicated manufacturing process, and low refrigeration efficiency, and achieve good radiation refrigeration effects. The effect of low cost and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

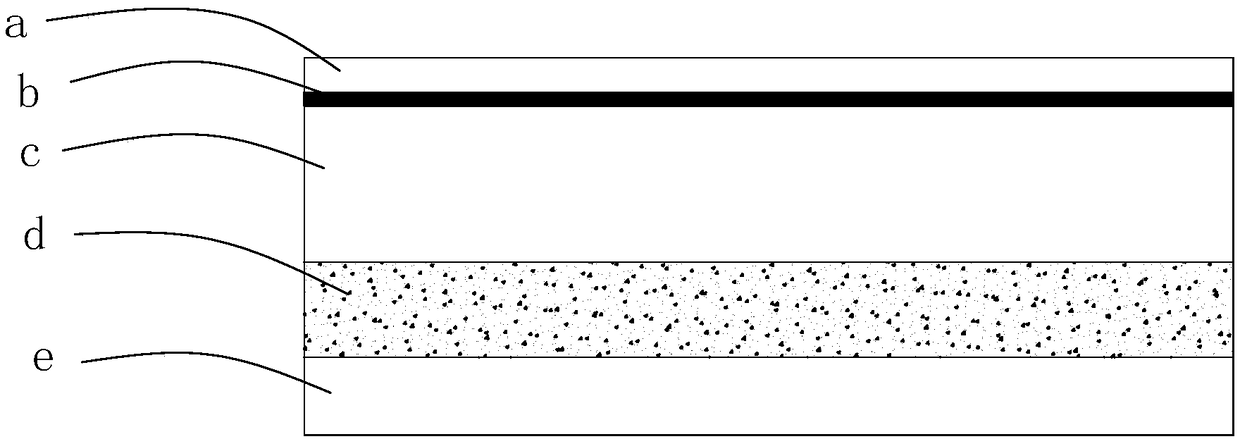

[0039] This embodiment provides a radiation cooling film. The radiation cooling film includes a coating layer a, a metal layer b, a transparent polyester PET layer c, an adhesive d and a release protective film e arranged in sequence, and the thickness is 50 μm. The ratio of the thickness of the layer to the total thickness of the radiative cooling film is as follows:

[0040] Coating layer a: 2%;

[0041] Metal layer b: 0.01%;

[0042] Transparent polyester PET layer c: 87.99%;

[0043] Mounting glue d: 5%;

[0044] Release protective film e: 5%.

[0045] In this embodiment, coating layer a includes polymethyl methacrylate paint, SiC with a particle size of 1 μm, benzotriazole ultraviolet absorber, nanoscale indium tin oxide antistatic agent, and indium tin oxide (ITO) Infrared absorber.

[0046] In this embodiment, SiC accounts for 1%wt of the entire coating layer a, the metal layer b is gold (Au), the transparent polyester PET is biaxially stretched PET, the mounting a...

Embodiment 2

[0048] This embodiment provides a radiation cooling film, which includes a coating layer a, a metal layer b, a transparent polyester PET layer c, an adhesive d and a release protective film e arranged in sequence, and the thickness is 150 μm. The ratio of the thickness to the total thickness of the radiative cooling film is as follows:

[0049] Coating layer a: 10%;

[0050] Metal layer b: 0.1%;

[0051] Transparent polyester PET layer c: 14.9%;

[0052] Mounting glue d: 40%;

[0053] Release protective film e: 35%.

[0054] In this embodiment, the coating layer a includes polybutylmethacrylate coating, SiO with a particle size of 15 μm 2 , benzotriazole ultraviolet absorber, ethoxylated aliphatic alkylamine antistatic agent and antimony tin oxide (ATO) infrared absorber.

[0055] In this example, SiO 2 Accounting for 10%wt of the entire coating layer a, the metal layer b is metal aluminum and silver. Transparent polyester PET, mounting adhesive d and release protective...

Embodiment 3

[0057] This embodiment provides a radiation cooling film, which includes a coating layer a, a metal layer b, a transparent polyester PET layer c, an adhesive d and a release protective film e from top to bottom, with a thickness of 120 μm, each layer The ratio of the thickness to the total thickness of the radiation cooling film is as follows:

[0058] Coating layer a: 4%;

[0059] Metal layer b: 0.03%;

[0060] Transparent polyester PET layer c: 70.97%;

[0061] Mounting glue d: 10%;

[0062] Release protective film e: 15%.

[0063] In this embodiment, the coating layer a includes polymethyl methacrylate paint, TiO with a particle size of 4 μm 2 , benzotriazole ultraviolet absorber, ethoxylated aliphatic alkylamine antistatic agent, and indium tin oxide (ITO) and antimony tin oxide (ATO) infrared absorber with a mass ratio of 1:1.

[0064] In this example, TiO 2 Accounting for 4%wt of the entire coating layer a, the metal layer b is metal chromium and titanium. The trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com