Reversible self-repair antibacterial acrylic coating and preparation and self-repair methods

A self-healing, acrylic technology, applied in coatings, antifouling/underwater coatings, paints containing biocides, etc. Good performance, good manufacturability and environmental protection characteristics, the effect of less chain entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Preparation of hyperbranched polysiloxane (referred to as HPSi) containing amino groups at the end

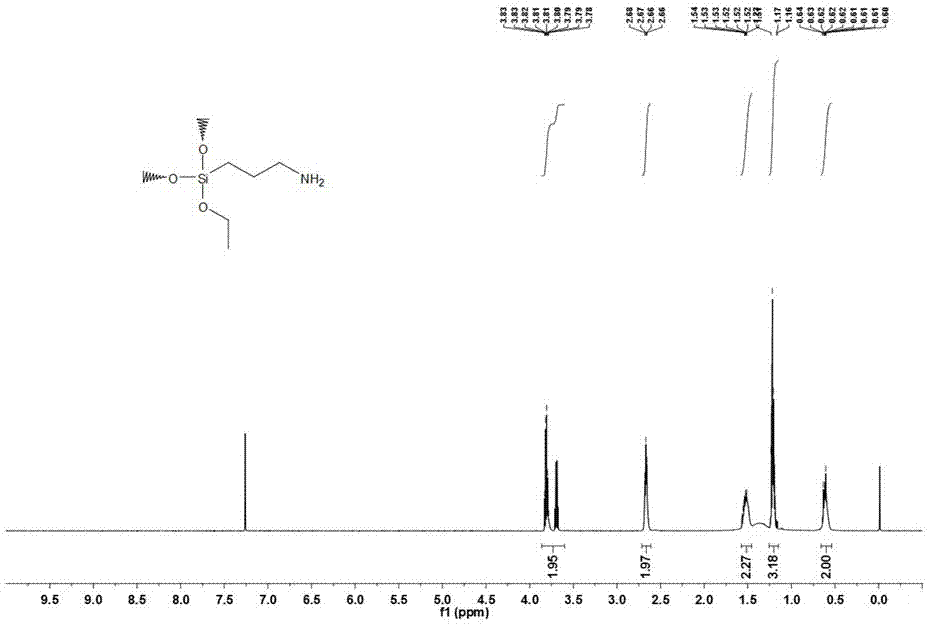

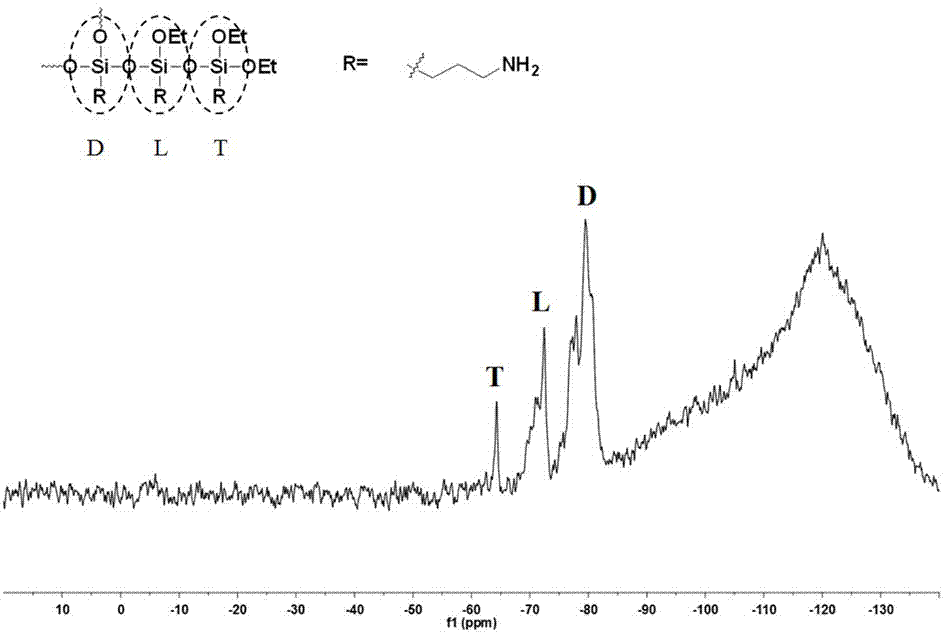

[0040] Under nitrogen protection, 44.0g of γ-aminopropyltriethoxysilane (KH550) and 4.3g of water were dissolved in 40.0mL of ethanol and reacted at 60°C for 4h. After the obtained solution was cooled to room temperature, the alcohol solvent was distilled off to obtain a colorless liquid, i.e. hyperbranched polysiloxane (HPSi) containing amino groups at the end. For its hydrogen NMR spectrum and silicon NMR spectrum, please refer to the attached figure 1 and 2 .

[0041] 2) Preparation of sulfonyl betaine methacrylate

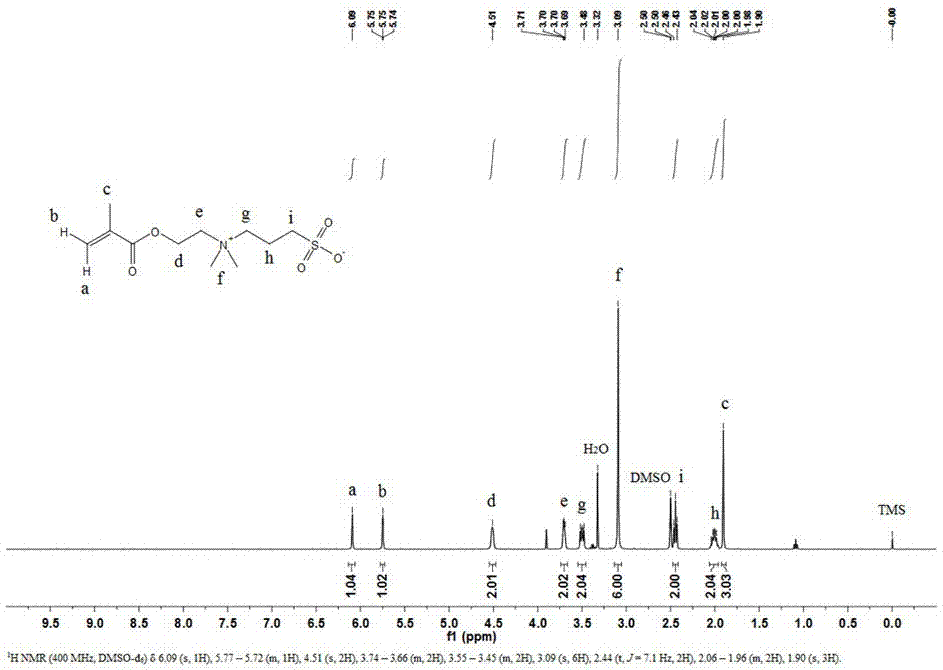

[0042] At room temperature, dissolve 15.7g of 2-(dimethylamino)ethyl methacrylate and 12.2g of 1,3-propane sultone in 100mL of 1,2-dichloroethane and stir evenly, then raise the temperature to 60°C and continue the reaction for 3h . The resulting mixed solution was cooled to room temperature and then filtered to obtain a white powder, i.e. sulfonyl...

Embodiment 2

[0063] 1) Preparation of hyperbranched polysiloxane (referred to as HPSi) containing amino groups at the end

[0064] Under the protection of argon, 44.0g of γ-aminopropyltriethoxysilane (KH550) and 4.3g of water were dissolved in 40.0mL of ethanol and reacted at 60°C for 4h. After the resulting solution was cooled to room temperature, the alcohol solvent was distilled off to obtain a colorless liquid, namely hyperbranched polysiloxane (HPSi) containing amino groups at the end.

[0065] 2) Preparation of sulfonyl betaine methacrylate

[0066] At room temperature, dissolve 15.7g of 2-(dimethylamino)ethyl methacrylate and 13.4g of 1,3-propane sultone in 100mL of 1,2-dichloroethane and stir evenly, then raise the temperature to 60°C and continue the reaction for 3h . The resulting mixture was cooled to room temperature and then filtered to obtain a white powder, namely sulfonyl betaine methacrylate.

[0067] 3) Preparation of linear acrylic resin containing sulfonyl betaine

...

Embodiment 3

[0075] 1) Preparation of hyperbranched polysiloxane (referred to as HPSi) containing amino groups at the end

[0076] Under the protection of a mixed gas of nitrogen and argon, 44.0g of γ-aminopropyltriethoxysilane (KH550) and 4.3g of water were dissolved in 40.0mL of ethanol and reacted at 60°C for 4h. After the resulting solution was cooled to room temperature, the alcohol solvent was distilled off to obtain a colorless liquid, namely hyperbranched polysiloxane (HPSi) containing amino groups at the end.

[0077] 2) Preparation of sulfonyl betaine methacrylate

[0078] At room temperature, dissolve 15.7g of 2-(dimethylamino)ethyl methacrylate and 15.0g of 1,3-propane sultone in 100mL of 1,2-dichloroethane and stir evenly, then raise the temperature to 60°C and continue the reaction for 3h . The resulting mixture was cooled to room temperature and then filtered to obtain a white powder, namely sulfonyl betaine methacrylate.

[0079] 3) Preparation of linear acrylic resin co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tenacity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com