Thermally-reversible self-repairing electrostatic dissipation polyurethane membrane and production method thereof

A static dissipative, polyurethane film technology, used in polyurea/polyurethane coatings, conductive coatings, coatings, etc., can solve problems such as R&D work that has not been reported yet, the decline of electrostatic conductivity, and the disappearance of self-healing ability, achieving excellent The effect of thermal stability, outstanding heat resistance, high self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of hyperbranched polysiloxane with maleimide group

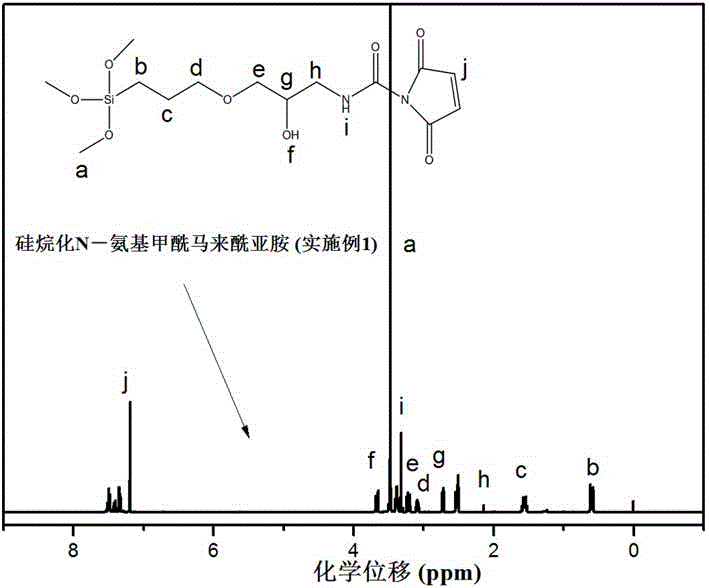

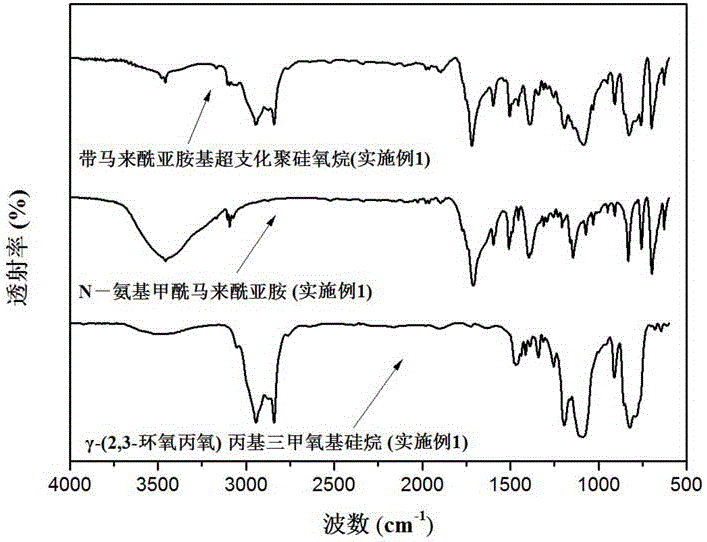

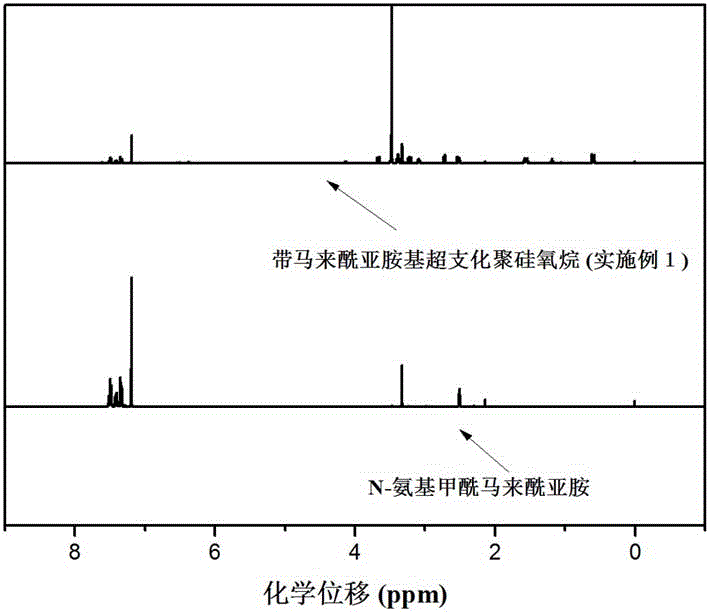

[0040] In N 2 Under the protection and magnetic stirring conditions, in a 250mL three-necked flask, 2.24g N-carbamoylmaleimide and 100mL toluene were thoroughly mixed; and then 3.584g γ-(2,3-epoxypropylene) was dropped into the three-necked flask. Oxygen) propyltrimethoxysilane. After the addition is complete, the three-neck flask is heated, and the reactants are reacted at a constant temperature of 50° C. for 6 hours. After the reaction, the solvent was distilled off under reduced pressure and dried under vacuum at room temperature to obtain the silanized N-carbamoyl maleimide. For its proton nuclear magnetic resonance spectrum, see attached figure 1 .

[0041] 0.2688 g of deionized water, 80 mL of ethanol and 0.01 g of tetramethylammonium hydroxide were added to the silanized N-carbamoyl maleimide, and then mixed thoroughly under stirring. Warm up to 50°C and react at constant temperature for 3 hours; a...

Embodiment 2

[0063] (1) Preparation of hyperbranched polysiloxane with maleimide group

[0064] In N 2 Under protection and stirring conditions, in a 250mL three-necked flask, 2.24g N-carbamoylmaleimide and 80mL toluene were thoroughly mixed; then 4.256g γ-(2,3-epoxypropoxylate) was dropped into the three-necked flask. ) Propyl trimethoxysilane. After the dripping was completed, the three-neck flask was heated to 55°C and reacted at a constant temperature for 7 hours. After the reaction, the solvent was distilled off under reduced pressure, and vacuum dried at room temperature to obtain silanized N-carbamoyl maleimide.

[0065] To the silanized N-carbamoyl maleimide, add 0.448g deionized water, 90mL ethanol, methanol, propanol, n-butanol mixture and 0.009g tetramethylammonium hydroxide, and under mechanical stirring conditions , Mix thoroughly. The temperature was raised to 50° C. and reacted at a constant temperature for 5 hours; after the reaction, the solvent was distilled off under reduc...

Embodiment 3

[0072] (1) Preparation of hyperbranched polysiloxane with maleimide group

[0073] In N 2 Under protection and stirring conditions, in a 250mL three-necked flask, 2.24g of N-carbamoylmaleimide and 90mL toluene were thoroughly mixed; then 3.607g of γ-(2,3-epoxypropoxylate) was dropped into the three-necked flask. ) Propyl trimethoxysilane. After the addition, the three-neck flask was heated to 60° C. and reacted at a constant temperature for 6 hours. After the reaction, the solvent was distilled off under reduced pressure, and dried under vacuum at 45° C. to obtain silanized N-carbamoyl maleimide.

[0074] To the silanized N-carbamoyl maleimide, add 0.2748 g of deionized water, 80 mL of ethanol, and 0.0091 g of a mixture of tetramethylammonium hydroxide and tetraethylammonium hydroxide, and under magnetic stirring, fully mixing. The temperature was raised to 55° C. and reacted at a constant temperature for 4 hours; after the reaction, the solvent was distilled off under reduced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com