Photovoltaic waterproof coiled material for roof and preparation method for photovoltaic waterproof coiled material

A waterproofing membrane and photovoltaic technology, applied in the direction of roofing, photovoltaic power generation, roof covering, etc., can solve the problems of high comprehensive cost, complex on-site operation, and great influence of human factors on quality, and achieve high roof area utilization and integrity. Good, the effect of reducing the installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

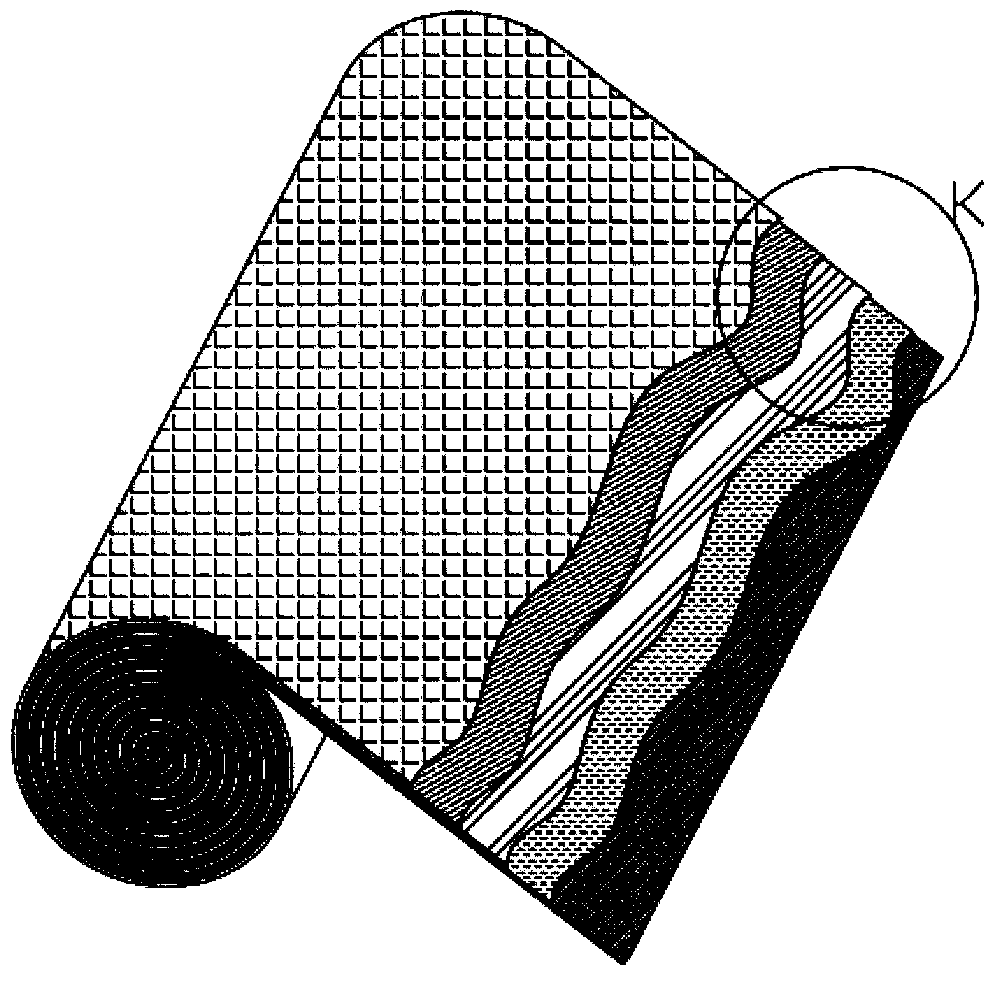

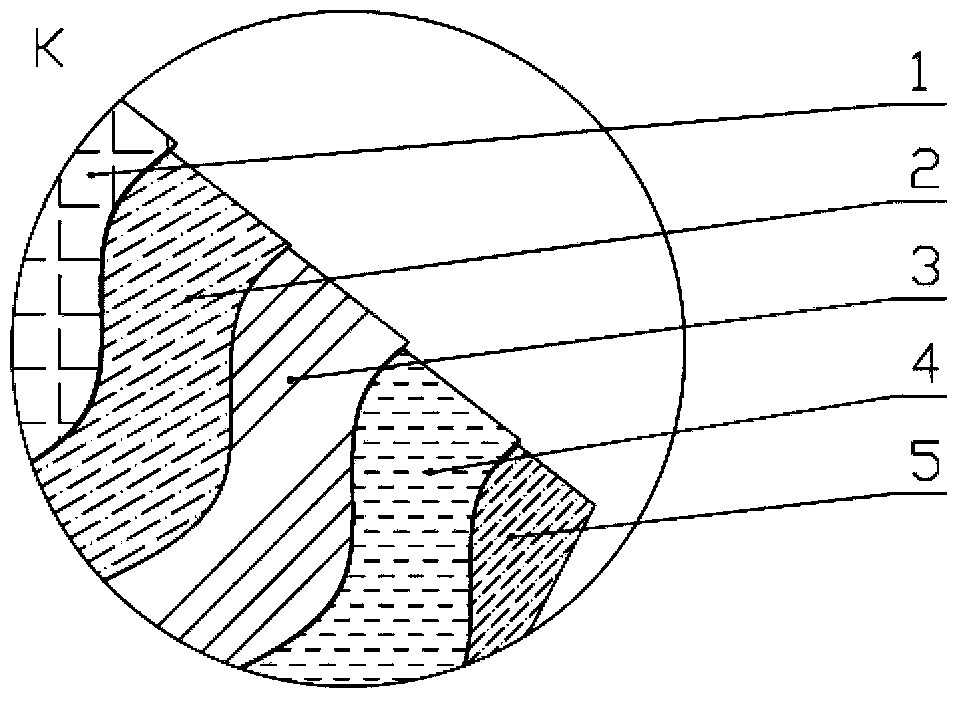

[0030] Such as figure 1 and figure 2 As shown, a photovoltaic waterproof membrane for roofing has a layered structure, including a waterproof membrane substrate 1, a flexible thin-film photovoltaic cell module 3, a film layer 4 and a paint layer 5 from inside to outside. The waterproof membrane substrate 1 is EPDM waterproof membrane; the thickness of the waterproof membrane substrate 1 is 2.0 mm; the flexible thin film photovoltaic cell module 3 is an amorphous silicon flexible solar thin film cell; the The film layer 4 is a fluorine-containing TPT polyester film or ethylene-tetrafluoroethylene copolymer film (ETFE) with a thickness of 250um; the coating layer 5 is a nano-scale organosilicon-modified acrylic paint with a thickness of 30um.

[0031] The roof photovoltaic waterproof membrane also includes an adhesive layer 2, which is composed of Sika's single-component high-modulus polyurethane sealing adhesive Sikaflex-11FC (Pro), which bonds the waterproof membrane substra...

Embodiment 2

[0034] A roof photovoltaic waterproof membrane, the waterproof membrane substrate 1 is a thermoplastic polyolefin waterproof membrane; the waterproof membrane substrate 1 is a single-layer structure with a thickness of 1.2mm; the flexible film photovoltaic cell assembly 3 is an organic thin film battery; the coating layer 5 is a nanoscale fluorocarbon coating with a thickness of 70um, and the others are the same as in Example 1.

Embodiment 3

[0036] A roof photovoltaic waterproof membrane, the waterproof membrane substrate 1 is EPDM waterproof membrane; the thickness of the waterproof membrane substrate 1 is 1.8mm; the flexible thin film photovoltaic cell assembly 3 is copper indium Potassium selenium thin-film solar cell; the coating layer 5 is a nano-scale organosilicon-modified acrylic coating with a thickness of 50 um, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com