UV resistant agent used for acrylic coating and preparation method and application thereof

An anti-ultraviolet agent, acrylic technology, applied in the direction of coating, etc., can solve the problems of decreased anti-ultraviolet ability, toxicity, limited stability, etc., and achieve the effect of improving anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

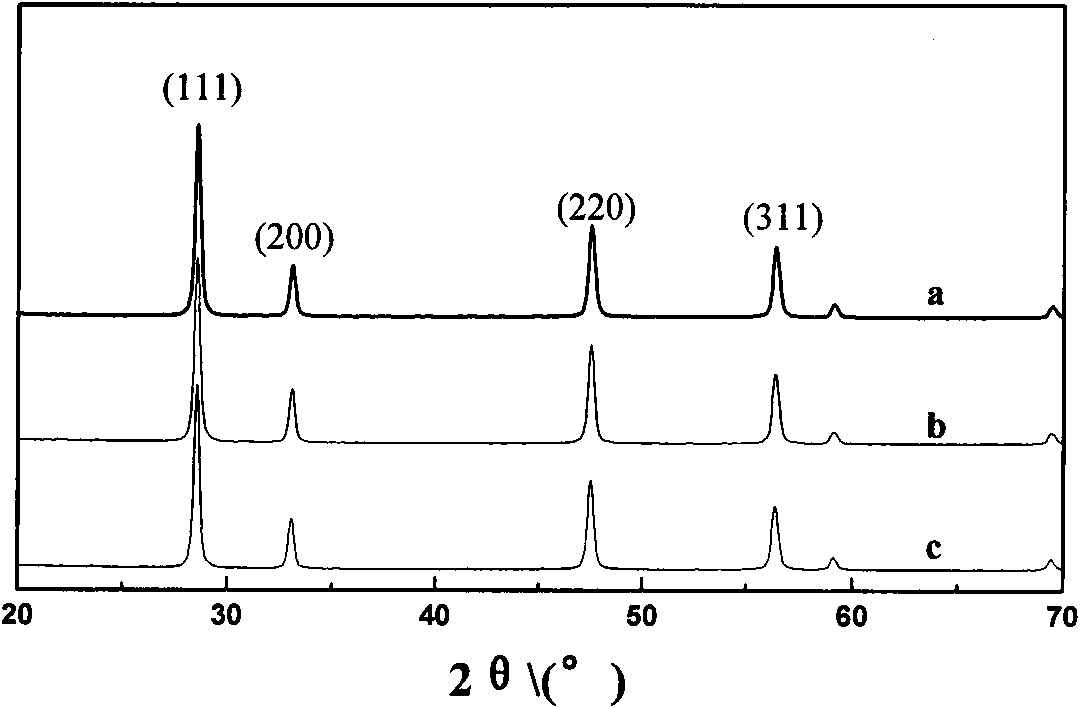

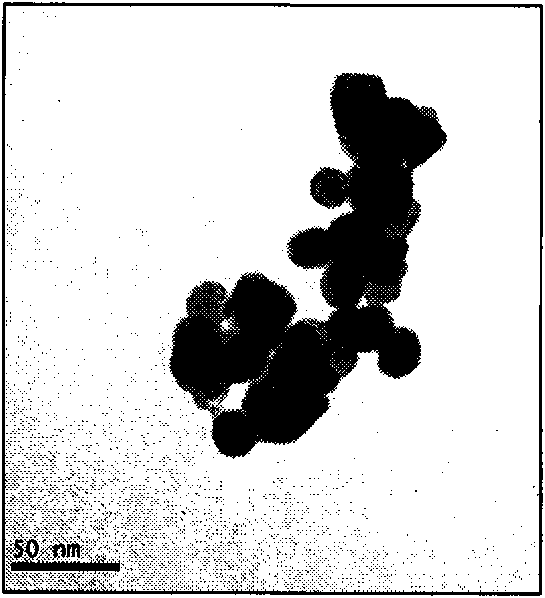

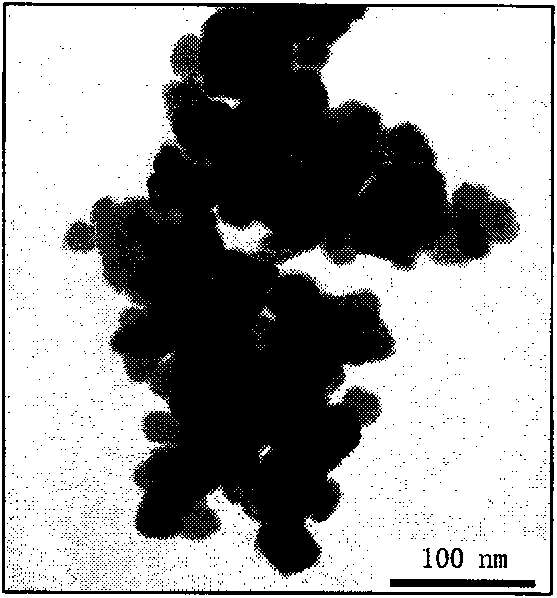

[0019] Example 1: Weighing CaCl with a molar ratio of 0.03:0.97 2 and Ce(NO 3 ) 3 ·6H 2 O was dissolved in distilled water and added dropwise to the carboxymethyl cellulose solution stirred at a constant speed. After the dropwise addition, at the reaction temperature of 25° C., ultrasonic reaction was performed for 2 h. Ca 0.03 -Ce 0.97 o 2 . Two solutions A and B are prepared, and the A solution is ultrasonically 30min, so that the nanoparticles can be uniformly dispersed in the solution. Then, uniformly and slowly add the B solution into the A solution dropwise, and ultrasonically hydrolyze. After the reaction, aging, suction filtration, washing, and vacuum drying to obtain the coated sample Ca 0.03 -Ce 0.97 o 2 -SiO 2 . Weigh the silane coupling agent and add it to ethanol, add dropwise the oxalic acid solution until the pH value is 3, stir and hydrolyze at room temperature for 1 hour, add a known amount of prepared coated sample, and perform ultrasonic couplin...

Embodiment 2

[0022] Example 2: Weighing CaCl with a molar ratio of 0.06:0.94 2 and Ce(NO 3 ) 3 ·6H 2 O was dissolved in distilled water and added dropwise to the carboxymethyl cellulose solution stirred at a constant speed. After the dropwise addition, at the reaction temperature of 27° C., ultrasonic reaction was performed for 4 h. Ca 0.06 -Ce 0.94 o 2 . Two solutions A and B are prepared, and the A solution is ultrasonically 30min, so that the nanoparticles can be uniformly dispersed in the solution. Then, uniformly and slowly add the B solution into the A solution dropwise, and ultrasonically hydrolyze. After the reaction, aging, suction filtration, washing, and vacuum drying to obtain the coated sample Ca 0.06 -Ce 0.94 o 2 -SiO 2 . Weigh the silane coupling agent and add it to ethanol, add dropwise the oxalic acid solution until the pH value is 4, stir and hydrolyze at room temperature for 1 hour, add a known amount of prepared coated sample, and perform ultrasonic couplin...

Embodiment 3

[0025] Example 3: Weighing CaCl with a molar ratio of 0.09:0.91 2 and Ce(NO 3 ) 3 ·6H 2 O was dissolved in distilled water and added dropwise to the carboxymethyl cellulose solution stirred at a constant speed. After the dropwise addition was completed, the reaction was ultrasonically performed at a reaction temperature of 29° C. for 1 h. Ca 0.09 -Ce 0.91 o 2 . Two solutions A and B are prepared, and the A solution is ultrasonically 30min, so that the nanoparticles can be uniformly dispersed in the solution. Then, uniformly and slowly add the B solution into the A solution dropwise, and ultrasonically hydrolyze. After the reaction, aging, suction filtration, washing, and vacuum drying to obtain the coated sample Ca 0.09 -Ce 0.91 o 2 -SiO 2 . Weigh the silane coupling agent and add it to ethanol, add dropwise the oxalic acid solution until the pH value is 3, stir and hydrolyze at room temperature for 1 hour, add a known amount of prepared coated sample, and perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com