Lubricating oil composition and preparation method thereof

A technology of lubricating oil composition and lubricating oil base oil, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., and can solve the problem of unmentioned antioxidant composition coordination and compatibility, restriction of industrialization promotion, and unstable product appearance etc. to achieve good oxidation stability, enhanced comprehensive performance, excellent high-efficiency oxidation stability and anti-oxidant synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the lubricating oil composition provided by the invention comprises: mixing component A, component B, component C and optionally added component D, stirring at 20-60° C. until uniform and transparent.

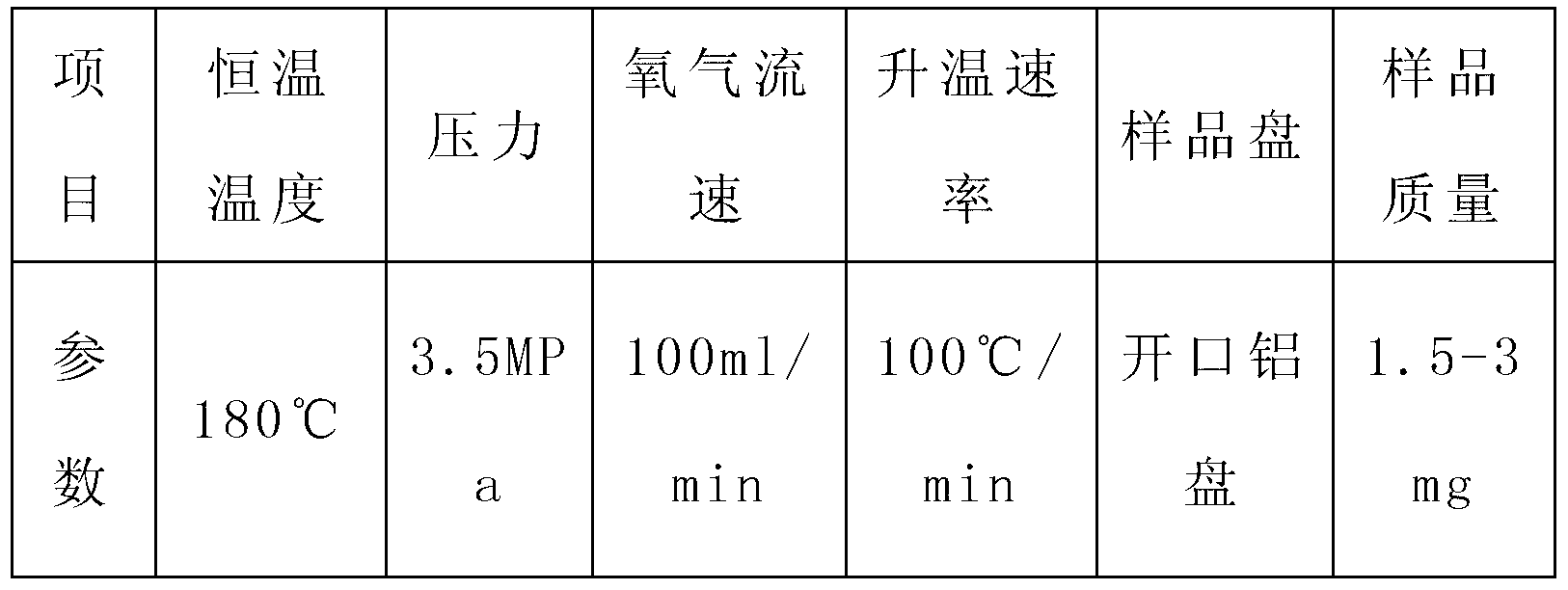

[0055] The present invention adopts lubricating oil oxidation stability measurement method (rotary oxygen bomb method) (BROT) and pressurized differential scanning calorimetry (PDSC) to evaluate oxidation properties respectively. BROT is a widely accepted method in the lubricating oil industry. The test method for rapid verification of oxidation stability, the method number is ASTM D2272-85 (SH / T0193-1992). Put the sample, distilled water and copper catalyst coil together in a glass sample container with a cover, and put it into the oxygen bomb equipped with a pressure gauge. The oxygen bomb is filled with oxygen at a pressure of 620KPa (6.2bar or 90psi) at room temperature and placed in an oil bath at a specified temperature (150°C). The oxyge...

Embodiment 1

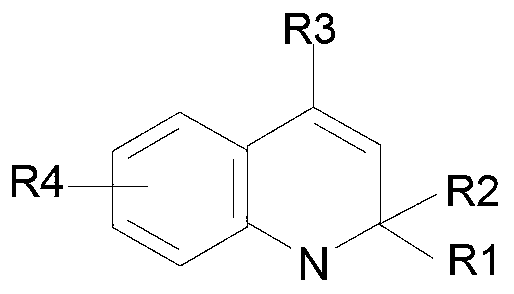

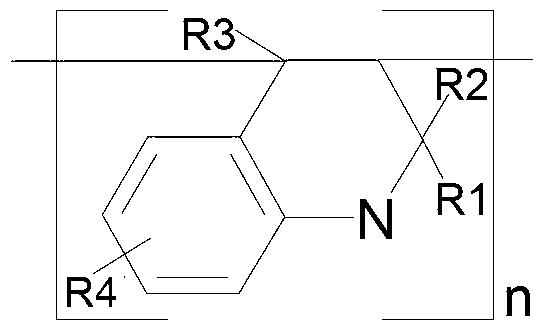

[0061] Put 85g of Group III oil 150N and 15g of nonyl trimellitate into a 200ml beaker, and then add 0.8g of Naugalube TMQ (2,2,4-trimethyl-1,2-dihydroquinoline anti Oxygen agent, Uniroyal Chemical Company, Inc., the same below) and 0.1g of benzotriazole derivative T551 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), stirred at 40°C until uniform and transparent to obtain a light yellow lubricating oil combination Object I, after 3 months of static storage, the color has no change.

Embodiment 2

[0065] Get 85g III type oil 150N and 15g nonyl trimellitate respectively and put into 200ml beaker, then add the Naugalube TMQ of 1.7g and the thiadiazole derivative T561 of 0.035g (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., under same), and stirred at 50°C until uniform and transparent to obtain light yellow lubricating oil composition III, which remained unchanged after 3 months of static storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com