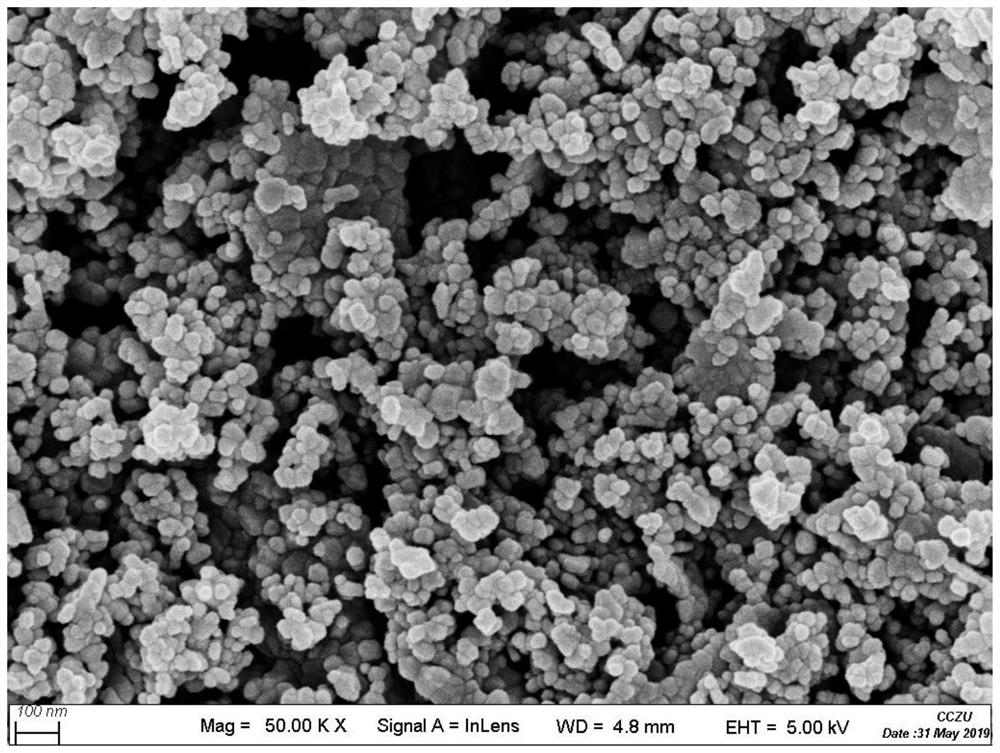

Preparation method of nano cerium oxide with strong ultraviolet shielding performance

A nano-cerium oxide and cerium oxide technology, which is applied in the preparation/treatment of rare earth metal compounds, cerium oxide/cerium hydroxide, nanotechnology, etc., can solve the problems of limited use, achieve performance improvement, strong performance, and reduce particle agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

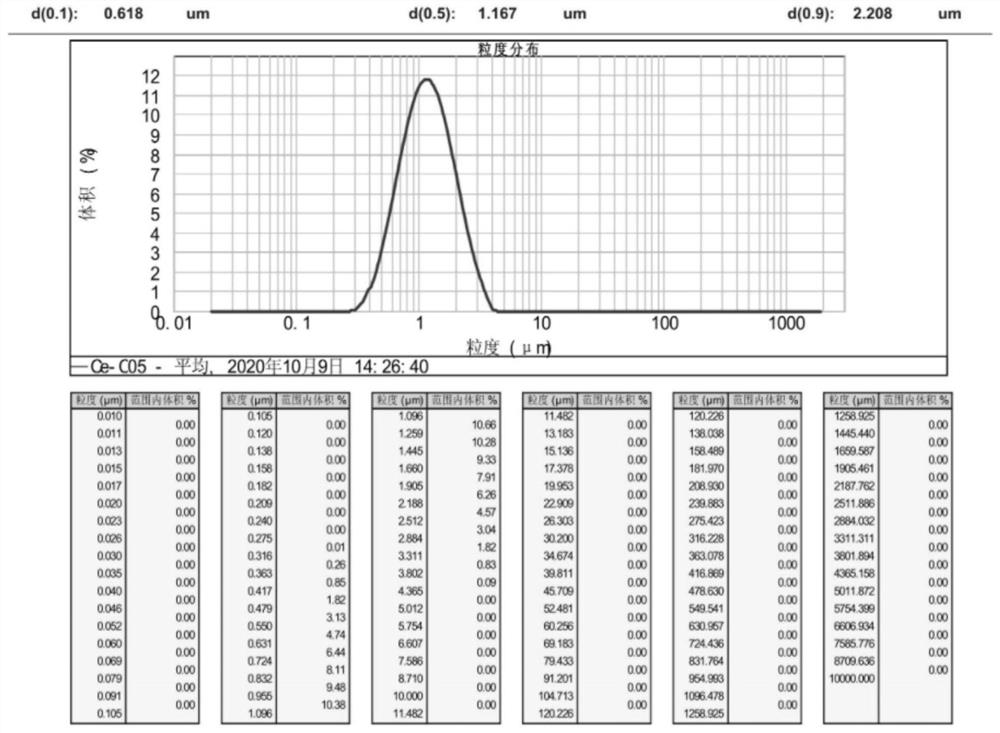

Embodiment 1

[0031] (1) using rare earth cerium chloride as raw material preparation concentration is the cerium chloride solution of 0.6mol / l;

[0032] (2) in the cerium chloride solution, add the calcium chloride solution that the concentration of the cerium oxide quality 6% of metering is 0.2mol / l, mix evenly, then add the sodium lauryl sulfate of the cerium oxide quality 4% of metering, Stir well.

[0033] (3) Sodium carbonate is mixed with the precipitating agent solution that concentration is 2.0mol / l, adopts diaphragm pump to drop in the step (2) rare earth cerium calcium chloride solution with the speed of 140ml / min then, after dropping, control The pH of the precipitate is 10-12, and the hydrogen peroxide with a concentration of 4 mol / l is added dropwise at a speed of 40 ml / min to oxidize the precipitate.

[0034] Wherein, the molar ratio of the measured cerium oxide to the precipitation agent is 1:4, and the molar ratio of the measured cerium oxide to hydrogen peroxide is 1:1. ...

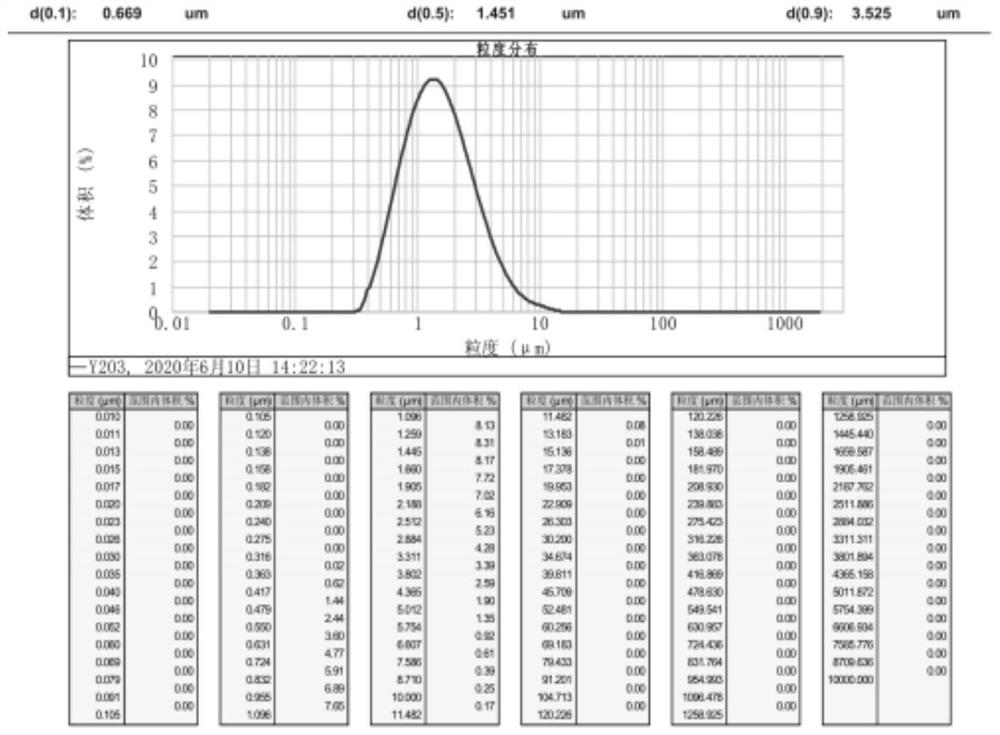

Embodiment 2

[0039] (1) using rare earth cerium chloride as raw material preparation concentration is the cerium chloride solution of 0.6mol / l;

[0040] (2) Adding the concentration of 8% of the mass of cerium oxide to the cerium chloride solution is 0.2mol / l calcium chloride solution, uniformly mixing, then adding sodium lauryl sulfate of 2% of the mass of cerium oxide, stirring uniform.

[0041] (3) Sodium carbonate is mixed with the precipitant solution that concentration is 2.0mol / l, adopts diaphragm pump to drop in the rare earth cerium calcium chloride solution with the speed of 140ml / min then, after dropping, control the pH of precipitate 10-12, then dropwise add hydrogen peroxide with a concentration of 4mol / l at a rate of 40ml / min to oxidize the precipitate.

[0042] Wherein, the molar ratio of the measured cerium oxide to the precipitation agent is 1:4, and the molar ratio of the measured cerium oxide to hydrogen peroxide is 1:1.

[0043] (4) Stir for 1 hour after the addition ...

Embodiment 3

[0047] (1) preparation concentration is the rare earth cerium chloride of 0.8mol / l as raw material;

[0048](2) Add the calcium chloride solution that the quality 8% of metered cerium oxide is 0.3mol / l in the cerium chloride solution, mix evenly, then add the sodium dodecylbenzenesulfonate of the quality 2% of metered cerium oxide , stir well.

[0049] (3) Sodium hydroxide is mixed with the precipitating agent solution that concentration is 1.0mol / l, adopts diaphragm pump to drop in the rare earth cerium chloride solution with the speed of 120ml / min then, after dropping, control the pH of precipitate 10-12, then dropwise add hydrogen peroxide with a concentration of 2mol / l at a rate of 30ml / min to oxidize the precipitate.

[0050] Wherein, the molar ratio of metered cerium oxide to precipitation agent is 1:3.8, and the molar ratio of oxygen metered cerium oxide to hydrogen peroxide is 1:1.

[0051] (4) Stir for 1 hour after the addition of hydrogen peroxide, age for 2 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com