Grinding pad

A polishing pad and foam technology, which is applied in the field of polishing pads, can solve the problems of difficult to achieve, difficult to achieve hardness, and unstable grinding amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

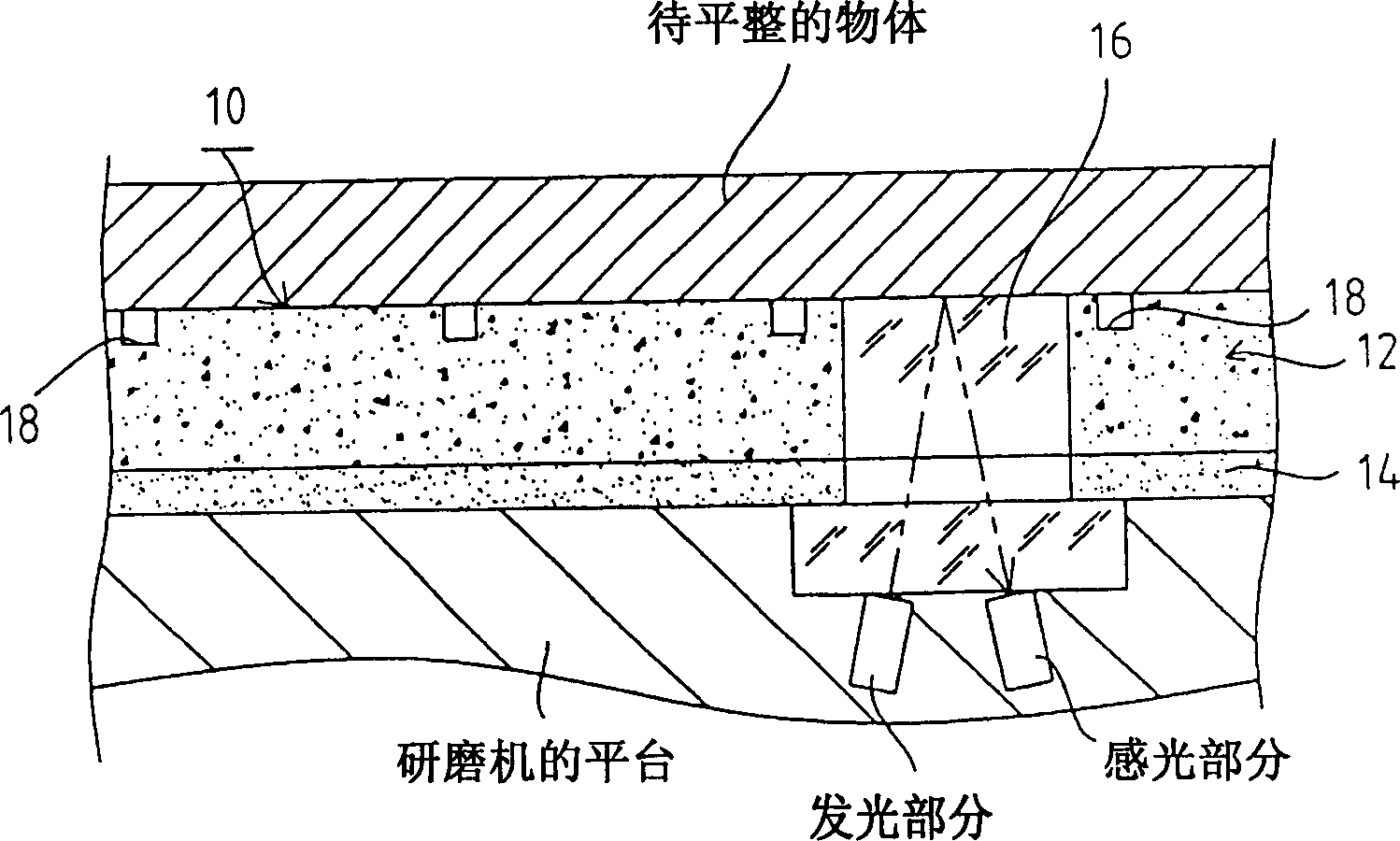

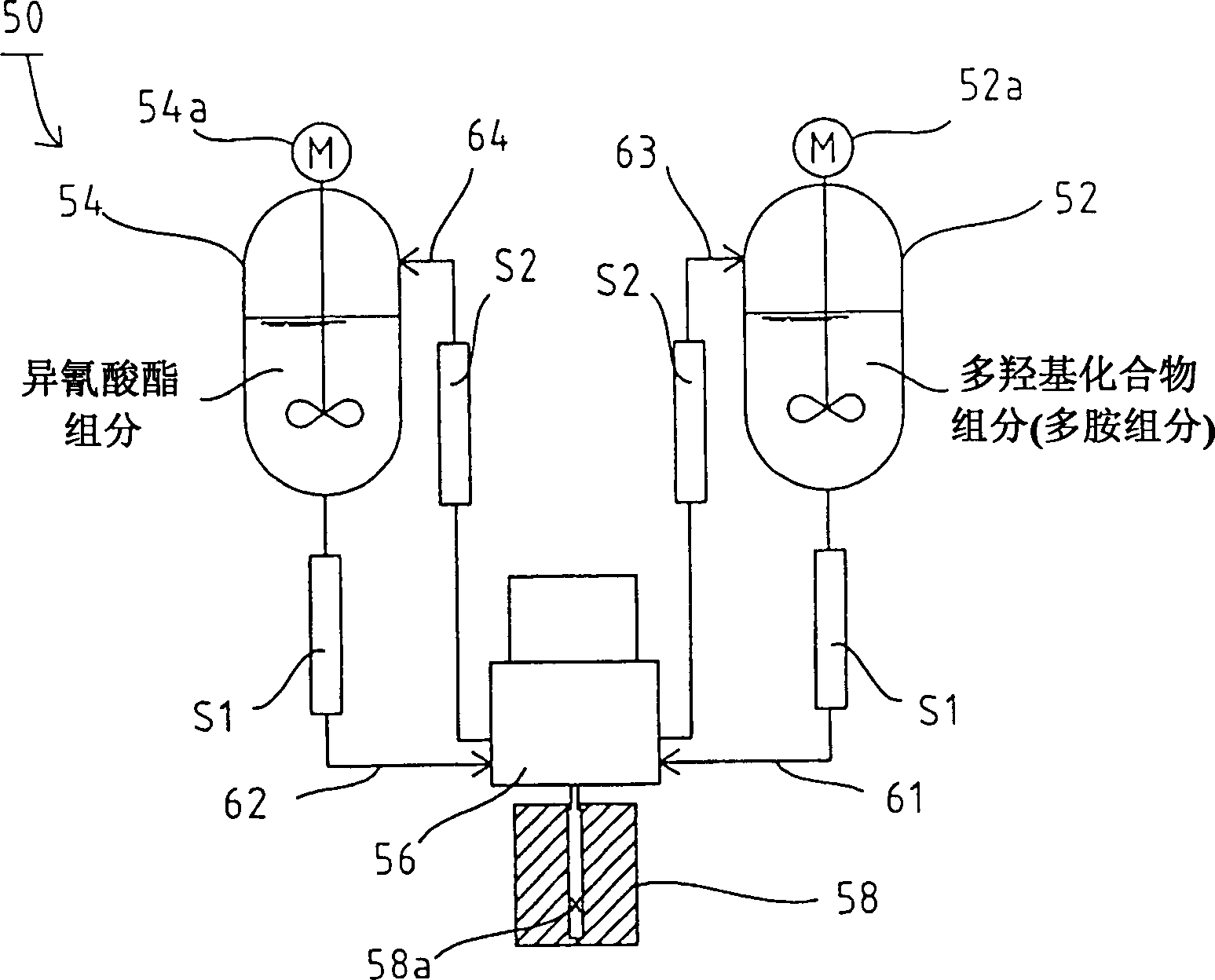

[0021] Hereinafter, the polishing pad of the present invention will be further described in detail with reference to preferred embodiments. The inventors found that while molding a gas-dissolved raw material by reaction injection molding, which is obtained by dissolving an inert gas in a polyurethane-based raw material, resistance to Urethane-based foams that are preferably used as polishing pads are capable of maintaining excellent polishing rates and step elimination properties subject to changes in polishing conditions. The inventors have also found that using aromatic diamines, for example as crosslinking agents, makes it possible to suppress changes in viscoelasticity, which depends on the temperature of polyurethane-based foams.

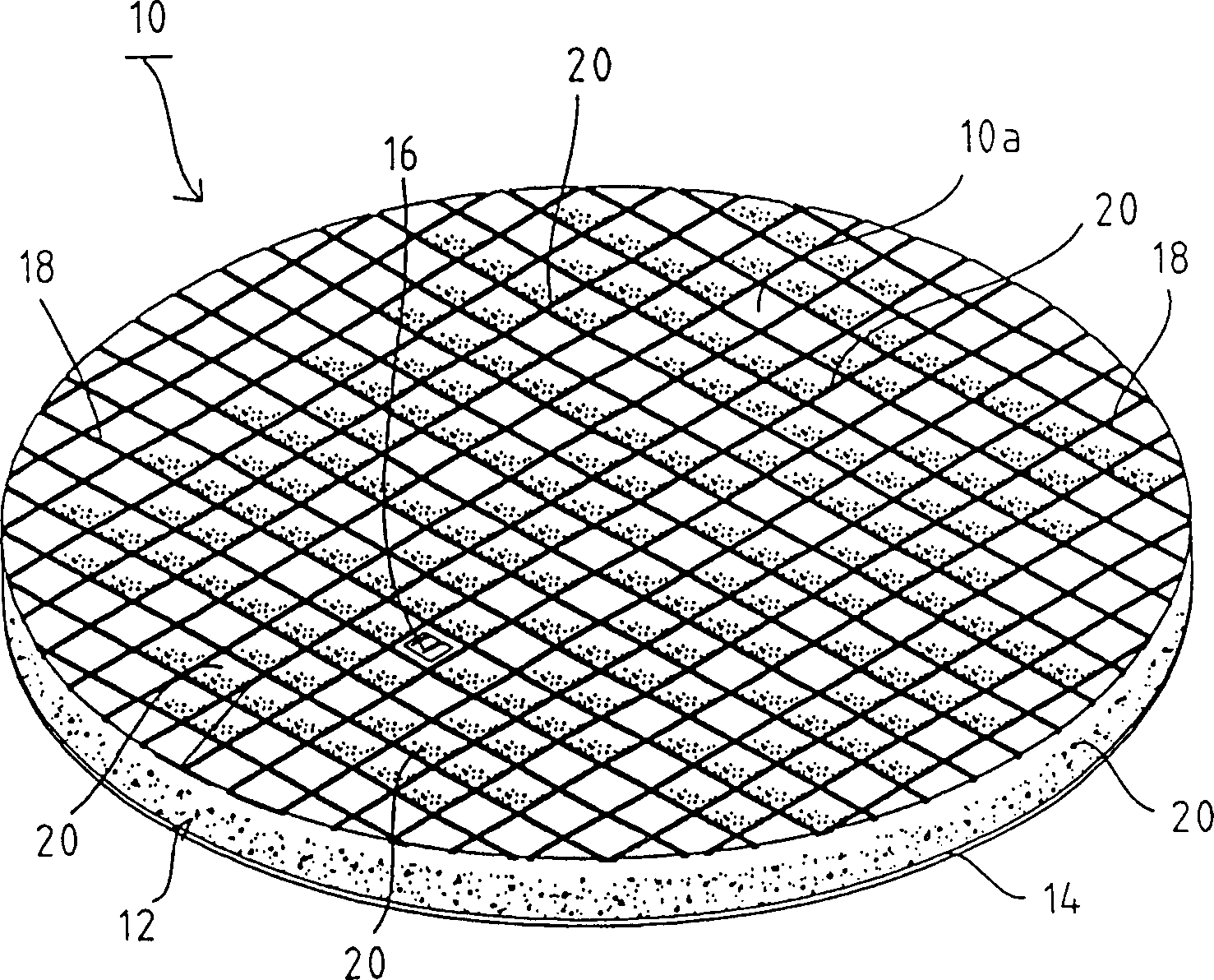

[0022] Such as figure 1 As shown, the polishing pad 10 of this embodiment exists in the form of a circular sheet and basically contains a polyurethane-based foam 12 constituting a polishing surface 10a and a cushioning pad 14 which is integral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com