Modified graphene reinforced polydicyclopentadiene composite material and preparation method thereof

A technology for polydicyclopentadiene and dicyclopentadiene is applied in the field of preparation of the composite material, which can solve problems such as being difficult to disperse, and achieve the effects of improving processability, increasing interface strength and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The modified graphene-reinforced polydicyclopentadiene nanocomposite material of this embodiment is obtained by blending and polymerizing the following main raw materials in parts by weight: 99 parts of polydicyclopentadiene and 1 part of modified graphene.

[0023] The preparation method of modified graphene reinforced polydicyclopentadiene nanocomposite of the present invention comprises the following steps:

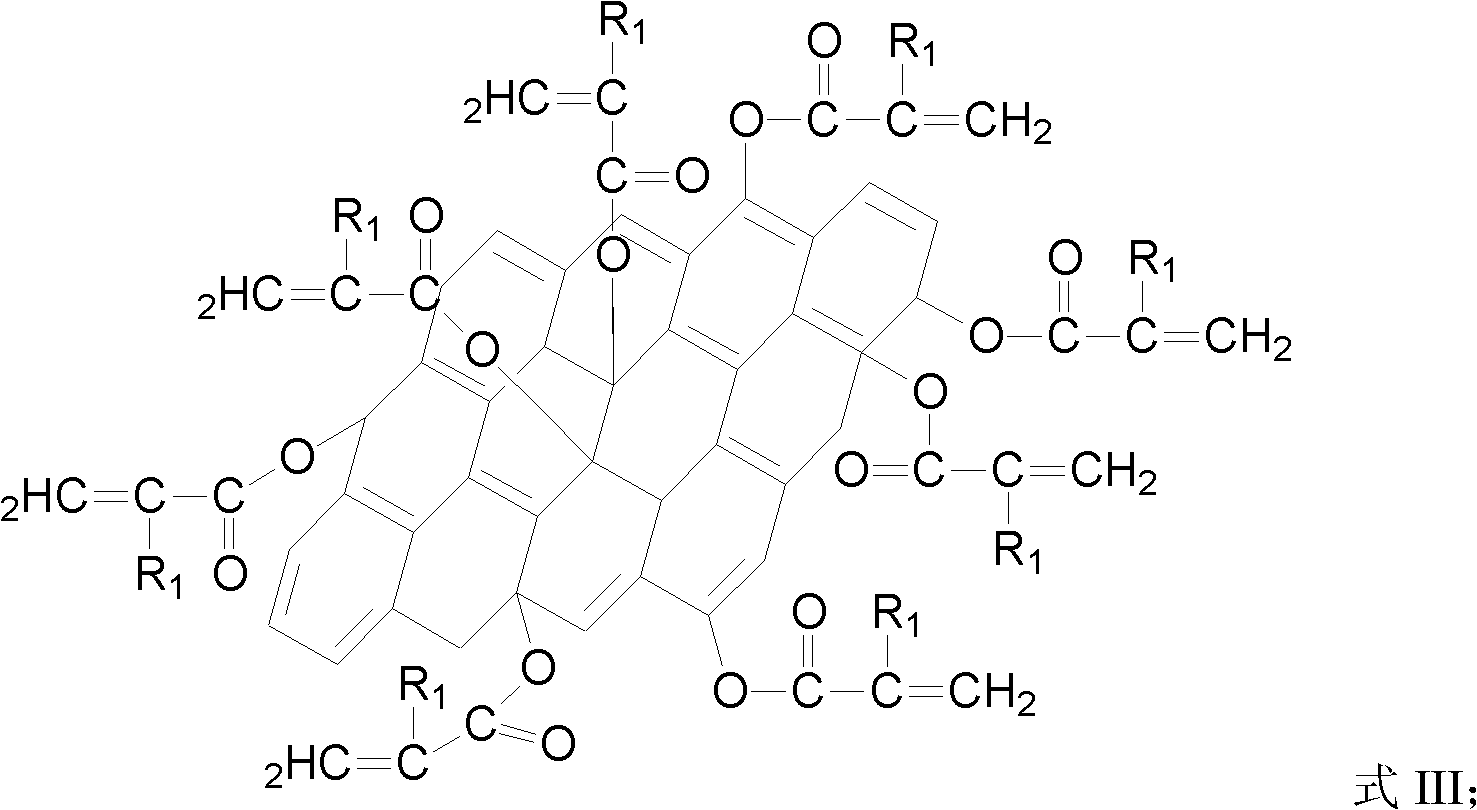

[0024] (1) 1 gram of graphene oxide prepared by the Hummer method is added to 30 grams of methyl methacrylate (i.e. R in formula II 1 is methyl, R 2 is methyl) modifier, add 0.5 gram of concentrated sulfuric acid, stir and react at 30 DEG C for 24 hours, after the reaction is finished, the modified graphene can be obtained by suction filtration with a microfiltration membrane;

[0025] (3) Under the condition of 45°C, 1 part by weight of modified graphene is uniformly dispersed in 99 parts by weight of dicyclopentadiene through ultrasonic vibration (ultrasonic ...

Embodiment 2

[0029] The modified graphene-reinforced polydicyclopentadiene nanocomposite material of this embodiment is obtained by blending and polymerizing the following main raw materials in parts by weight: 95 parts of polydicyclopentadiene and 5 parts of modified graphene.

[0030] The preparation method of modified graphene reinforced polydicyclopentadiene nanocomposite of the present invention comprises the following steps:

[0031](1) 1 gram of graphene oxide prepared by the Hummer method is added to 30 grams of butyl acrylate (i.e. R in formula II 1 for hydrogen, R 2 butyl) modifier, add 0.5 gram of dibutyltin dilaurate, stirred and reacted at 40°C for 20 hours, after the reaction, the modified graphene can be obtained by suction filtration with a microfiltration membrane;

[0032] (3) Under the condition of 45° C., 5 parts by weight of modified graphene are uniformly dispersed in 95 parts by weight of dicyclopentadiene through ultrasonic vibration to obtain a mixture of dicyclop...

Embodiment 3

[0036] The modified graphene-reinforced polydicyclopentadiene nanocomposite material of this embodiment is obtained by blending and polymerizing the following main raw materials in parts by weight: 97 parts of polydicyclopentadiene and 3 parts of modified graphene.

[0037] The preparation method of modified graphene reinforced polydicyclopentadiene nanocomposite of the present invention comprises the following steps:

[0038] (1) 1 gram of graphene oxide prepared by the Hummer method is added to 30 grams of hydroxyethyl methacrylate (i.e. R in formula II 1 is methyl, R 2 is hydroxyethyl) modifier, add 0.5 gram of tin protochloride, stir and react at 50 DEG C for 16 hours, after the reaction finishes, the modified graphene can be obtained by suction filtration with microfiltration membrane;

[0039] (3) Under the condition of 45° C., 3 parts by weight of modified graphene are uniformly dispersed in 97 parts by weight of dicyclopentadiene through ultrasonic vibration to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com