Flame-retardant polydicyclopentadiene composition, and thermosetting material and preparation method thereof

A technology of polydicyclopentadiene and dicyclopentadiene, which is applied in the field of flame-retardant polydicyclopentadiene composition and its thermosetting material and preparation, can solve the problems of large addition of flame-retardant effect and affecting the mechanical properties of products, etc. Achieve the effect of good flame retardant effect, small amount of addition, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

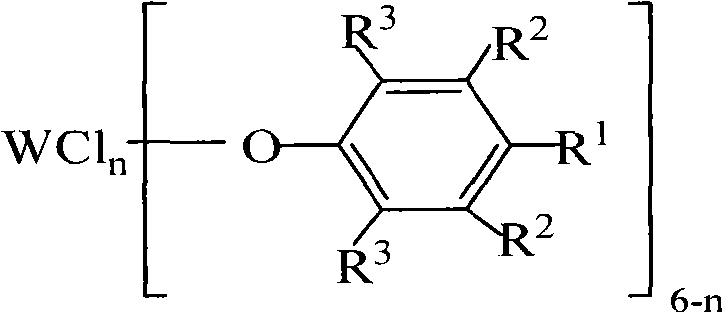

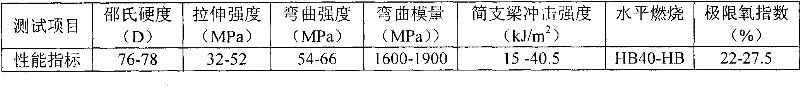

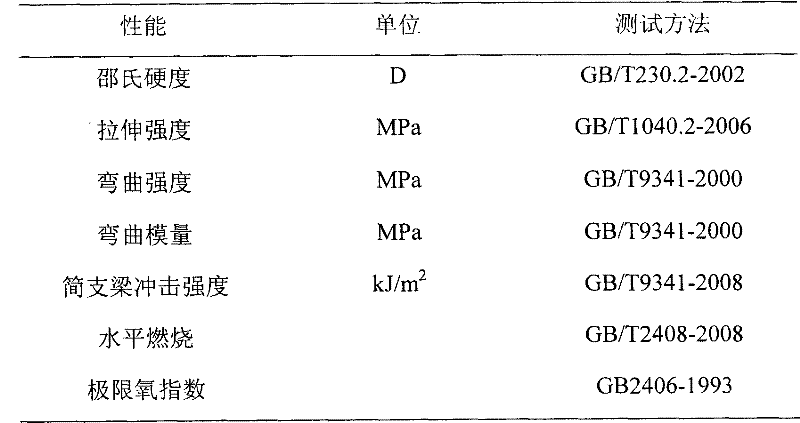

[0033] Under nitrogen protection, weigh 100 parts of DCPD in a three-necked flask, and then add 18 parts of BPS with a number average molecular weight of 3279. The material temperature is controlled at 70-90°C. After 4 hours of stirring, the BPS is completely dissolved in the DCPD monomer. After the material liquid is cooled to 25°C, it is divided into two parts, one of which is added with 2 parts of WCl modified by the main catalyst p-tert-butylphenol 6 , Form component A; add 1.2 parts of co-catalyst triethylaluminum to form component B. The two components A and B are quickly and fully mixed evenly under high-speed stirring, and injected into the mold. The mold temperature is maintained at 60 Demoulding at -80℃ for 4min to obtain PDCPD products. Product properties are shown in Table 2.

Embodiment 2

[0035] In addition to adding 6 parts of Sb to component A 2 O 3 Otherwise, the same as in Example 1.

Embodiment 3

[0037] In addition to adding 6 parts of Sb to component A 2 O 3 Except for 10 parts of aluminum hydroxide, the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com