Safety door structure made of PDCPD (Polydicyclopentadiene) material

A technology for safety doors and car doors, which is applied in doors, transportation and packaging, and vehicle parts, etc. It can solve problems such as unsatisfactory automobile lightweighting, achieve good coloring effects, improve side safety, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

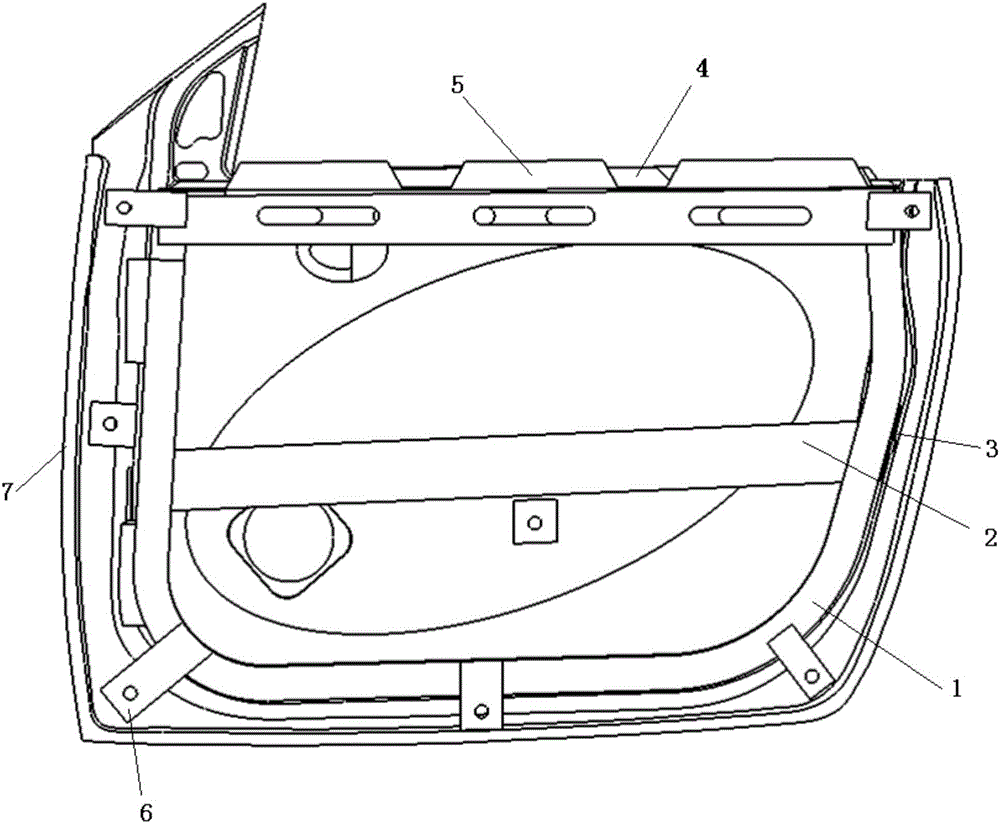

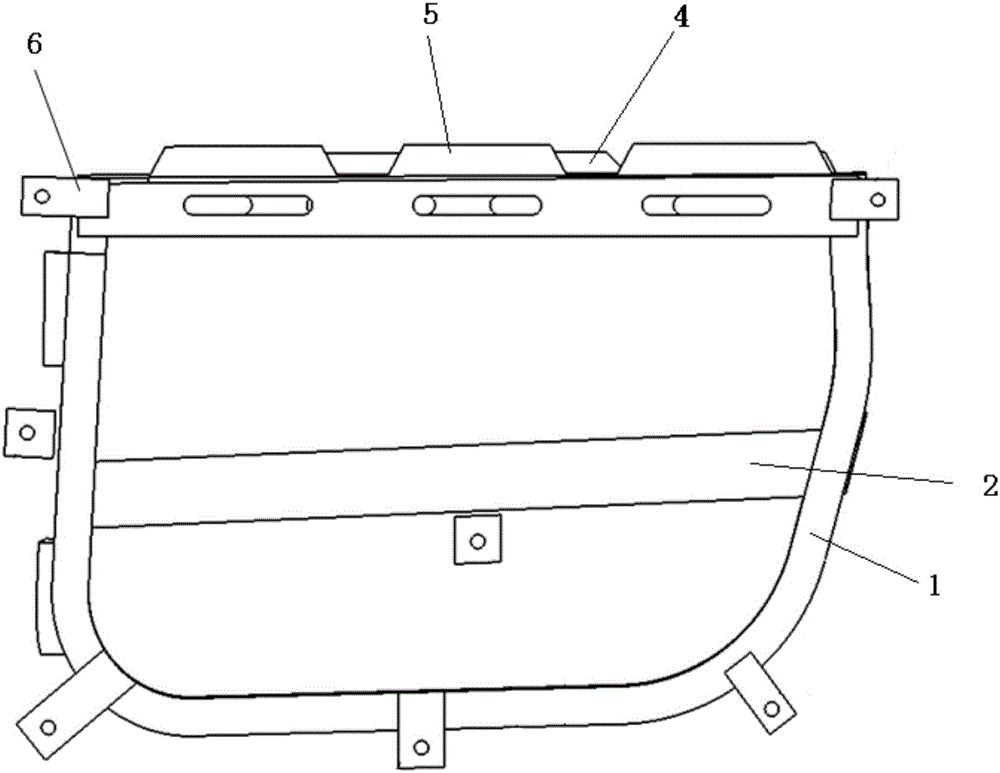

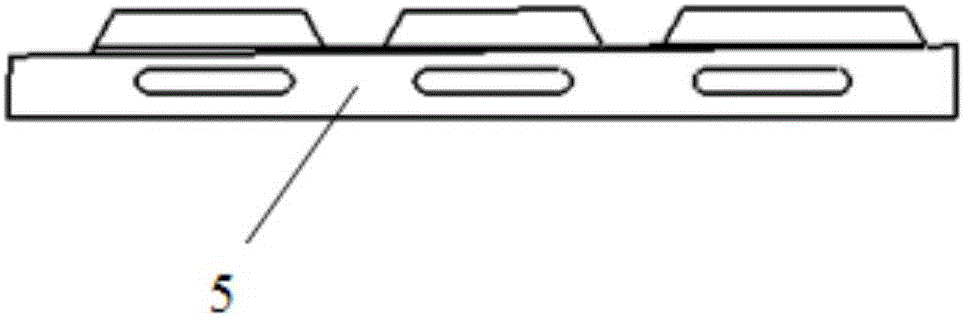

[0031] Such as Figures 1 to 6 shown. The invention discloses a safety door structure made of PDCPD material, comprising a U-shaped reinforcement frame 1 welded on the inner side of the outer panel of the car door, an anti-collision beam 2 transversely welded in the middle of the U-shaped reinforcement frame 1; the top of the U-shaped reinforcement frame 1 On the inner and outer sides, the outer reinforcing plate 4 and the inner reinforcing plate 5 are respectively transversely welded; the gap formed between the outer reinforcing plate 4 and the inner reinforcing plate 5 is used for installing the door glass. The U-shaped reinforcing frame 1 is formed by bending an aluminum profile with a rectangular cross section.

[0032] The reason why the reinforcement frame 1 of the present invention is not a rectangular frame fully considers the lifting problem of the door glass, and fully considers the height of the glass lifting. There is no beam at the upper end of the U-shaped rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com