A method of using a bearing seat structure of a skin-pass machine

A technology for bearing housings and light finishing machines, which is applied to the rigid support of bearing components, shafts and bearings, bearing components, etc., can solve the problems of time-consuming and laborious, many types and quantities of spare parts, and achieve convenient use, reduce types and quantities, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

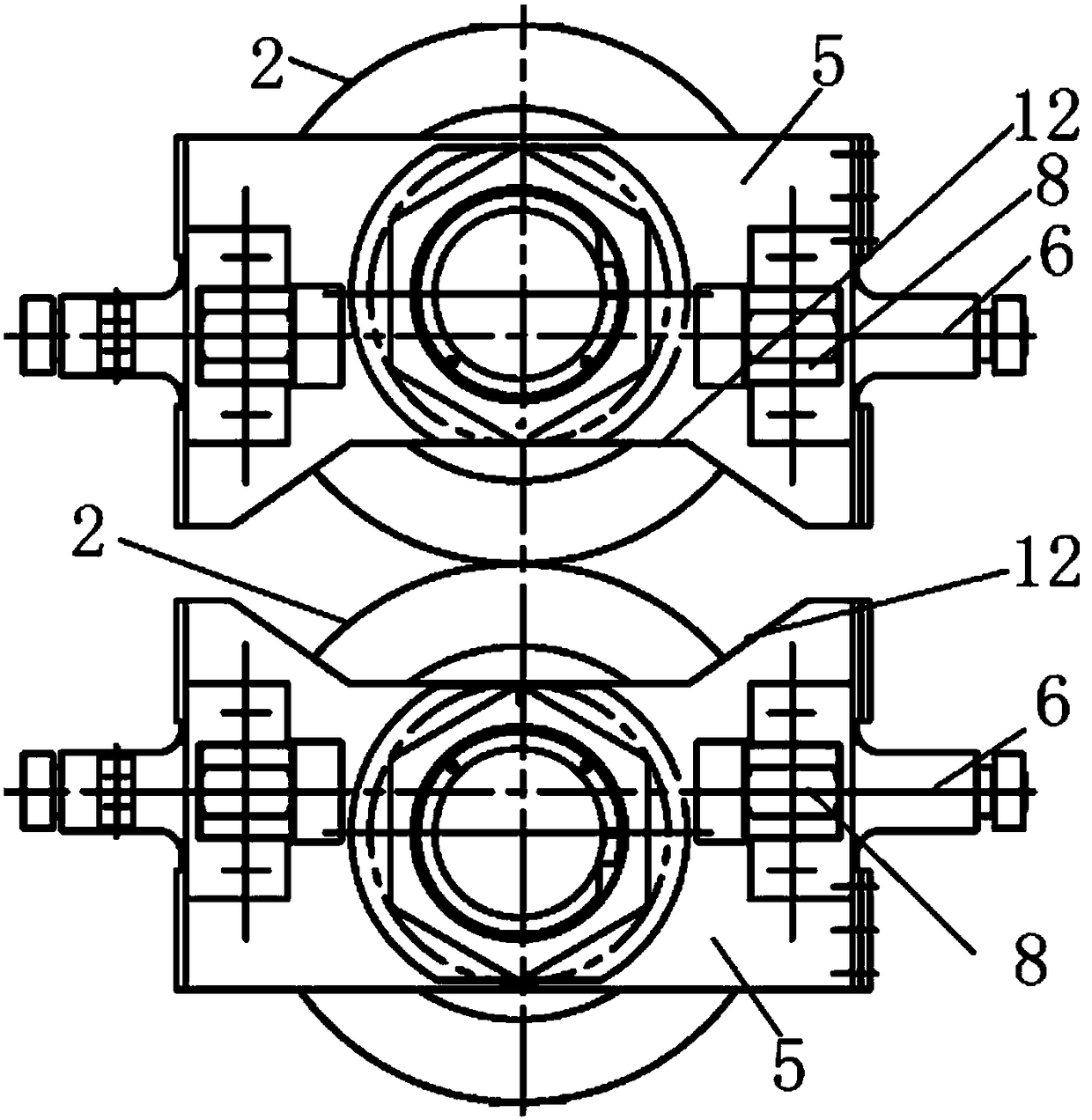

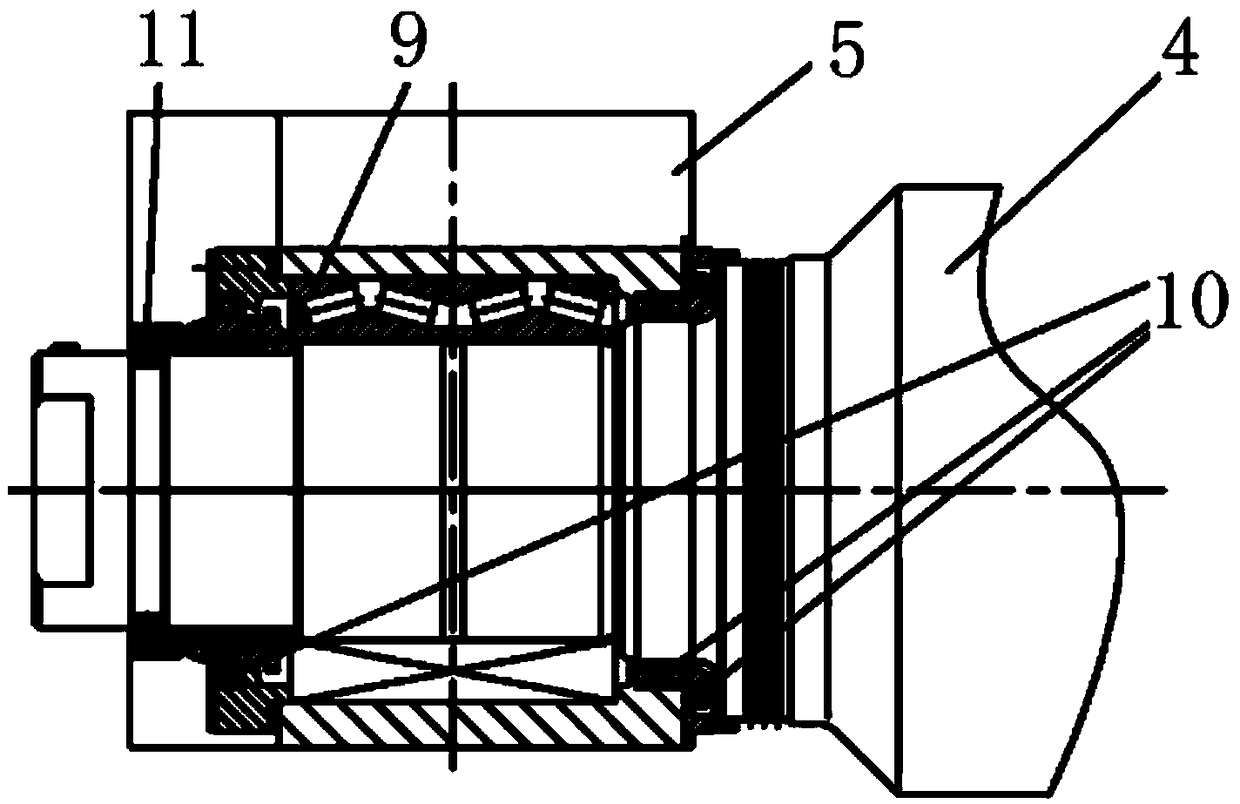

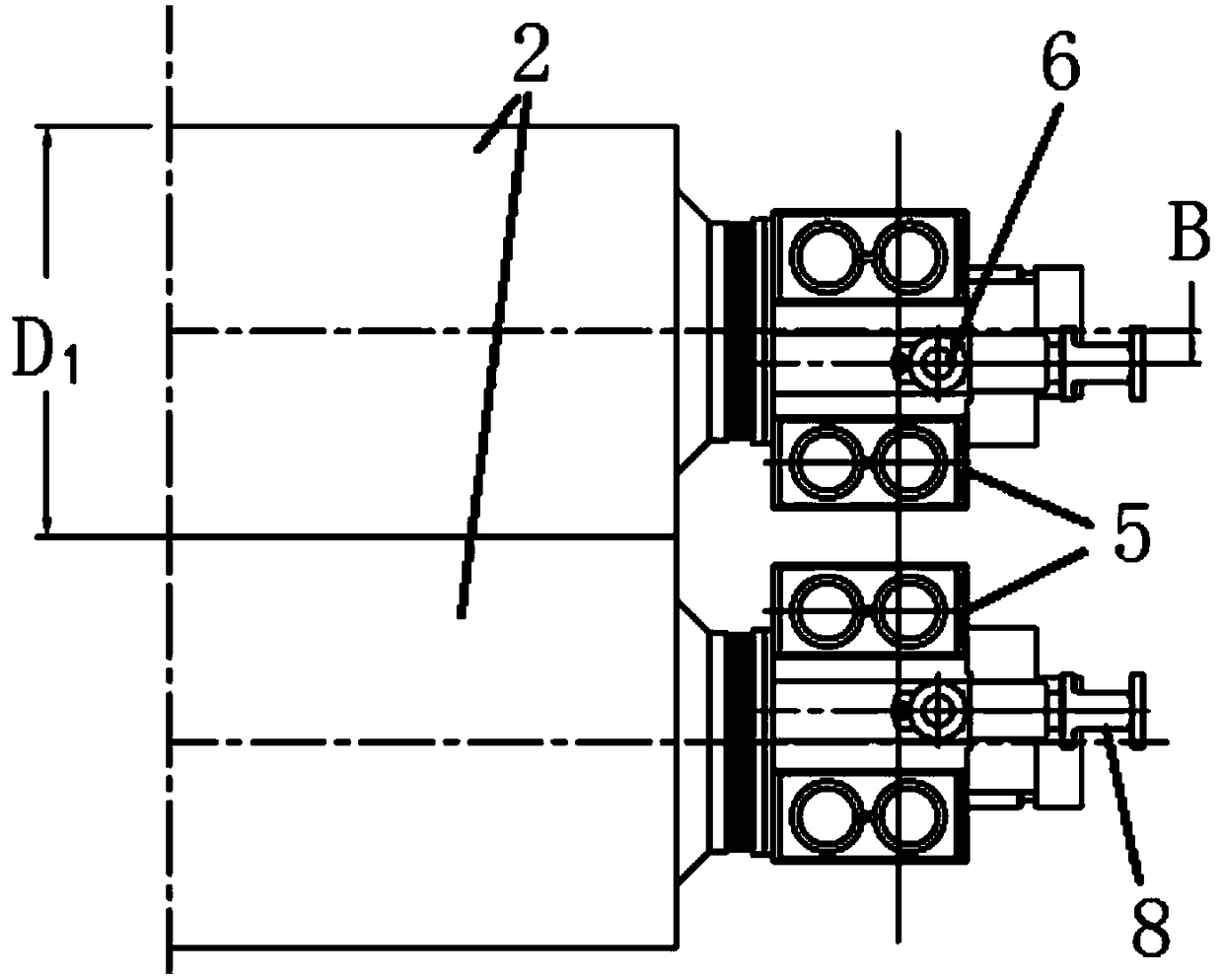

[0021] Such as figure 1 , figure 2 , the structure of the present invention is to include two pairs of bearing seats 5 arranged symmetrically up and down (each pair of bearing seats 5 includes a symmetrical one on the left and right sides, two pairs of four bearing seats 5 in total), and the axis lines of the two pairs of bearing seats 5 are parallel setting (the upper pair of bearing housings 5 are coaxially arranged, and the lower pair of bearing housings 5 are coaxially arranged), each bearing housing 5 is equipped with a work roll bearing 9, and the work roll bearings 9 are self-aligning rollers Bearings, each work roll bearing 9 is provided with a sealing ring 10 and a retaining ring 11 on both sides, and the two pairs of bearing housings 5 at the upper and lower positions pass through the work roll bearing 9 to have a work roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com