Solar energy heliostat gearing device

A transmission device and heliostat technology, applied in the field of transmission devices, can solve the problems of not being suitable for large-scale manufacturing and popularization, increasing the number of parts and structural dimensions, and high requirements for hydraulic system maintenance, so as to save manpower, save space, and ensure Effects on Safety and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The present invention uses tower type solar energy 100m 2 Take a heliostat drive as an example.

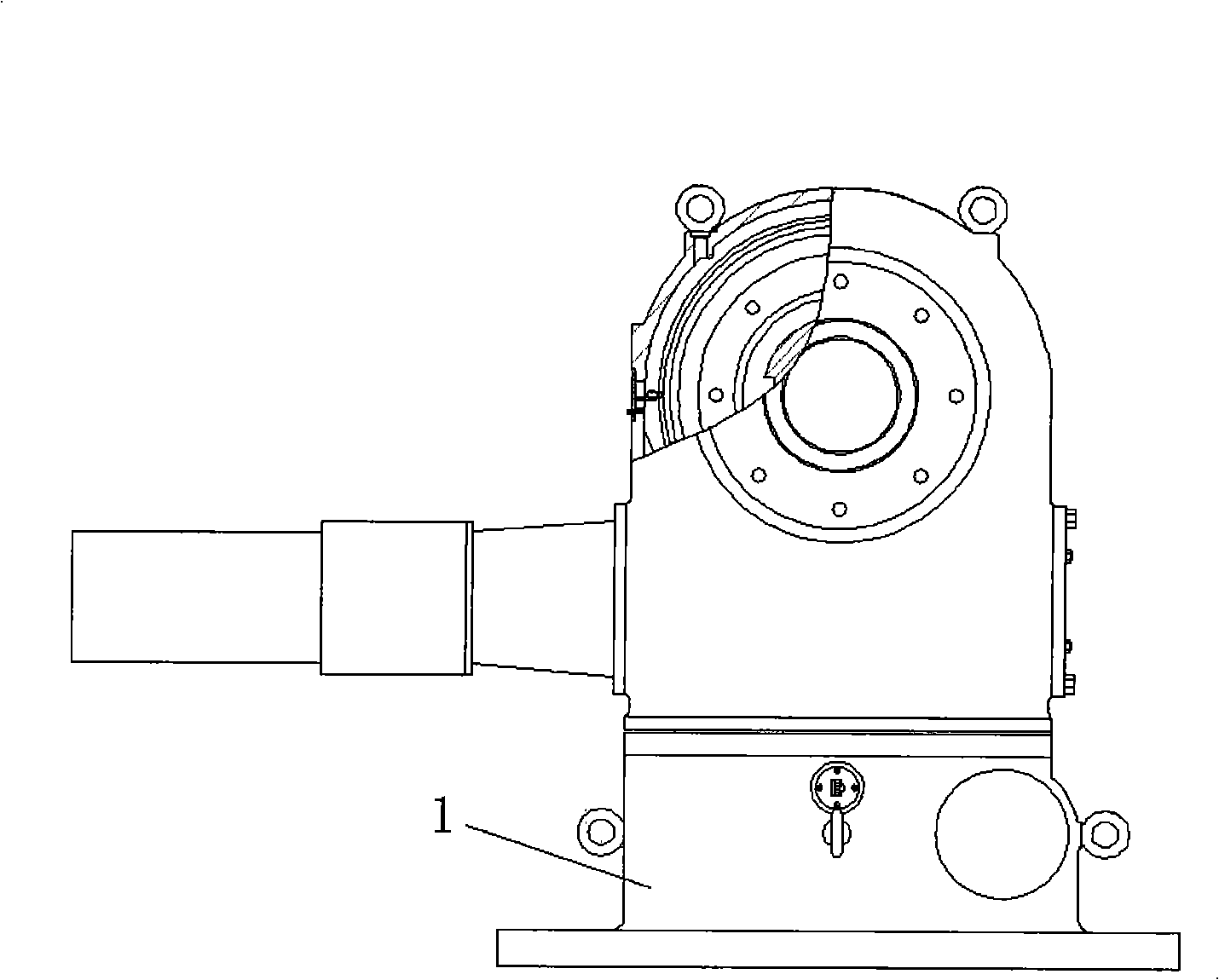

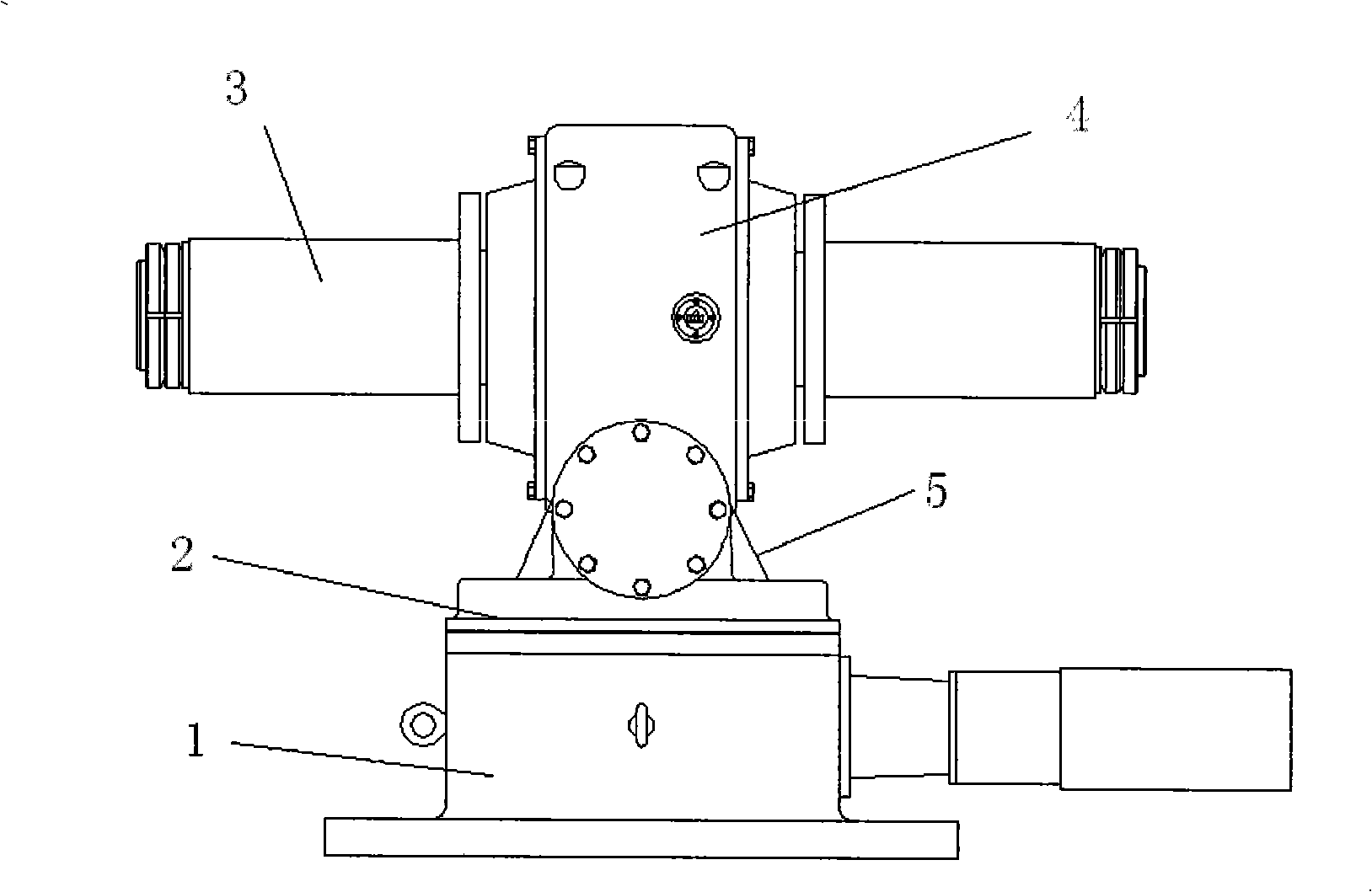

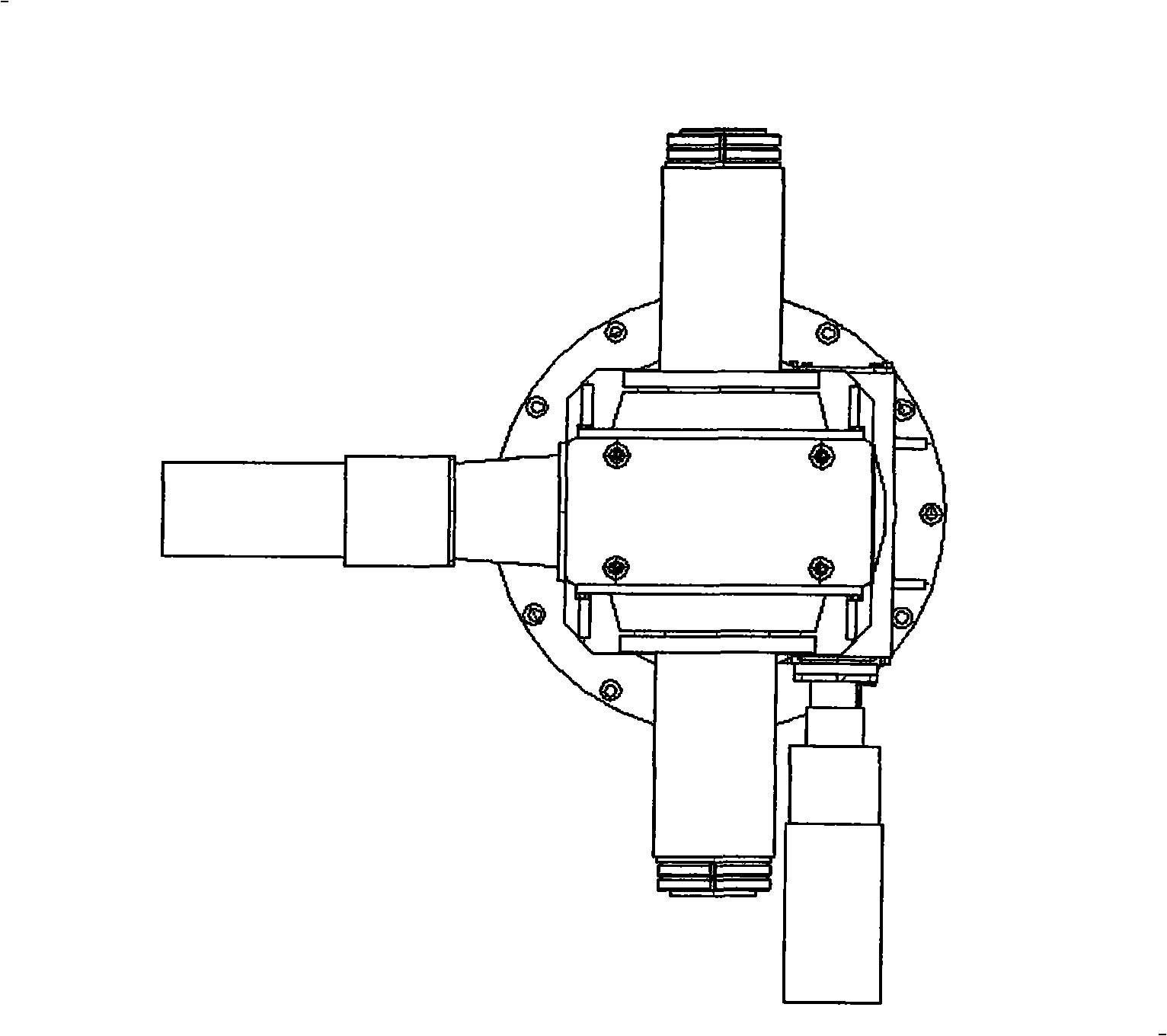

[0028] The overall structure of the solar heliostat transmission device of the present invention is as follows: figure 1 , 2 , as shown in 3, where figure 1 It is the front view of the solar heliostat transmission device of the present invention; figure 2 It is the left view of the solar heliostat transmission device of the present invention; image 3 It is a top view of the appearance of the solar heliostat transmission device of the present invention. The transmission device includes a lower box assembly 1 , a rotating mechanism 2 and an upper box assembly 4 . Among them, the upper box assembly 4 and the lower box assembly 1 are both processed and manufactured from steel materials, and the structure and wall thickness have been stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com