Organophosphorus based tungsten complex and preparation method and application thereof

A tungsten complex and organic phosphine technology, applied in the field of polymer synthesis, can solve the problems of being unsuitable for industrial production, harsh use conditions, poor stability, etc., and achieve the effects of good promotion and application prospects, low preparation cost, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

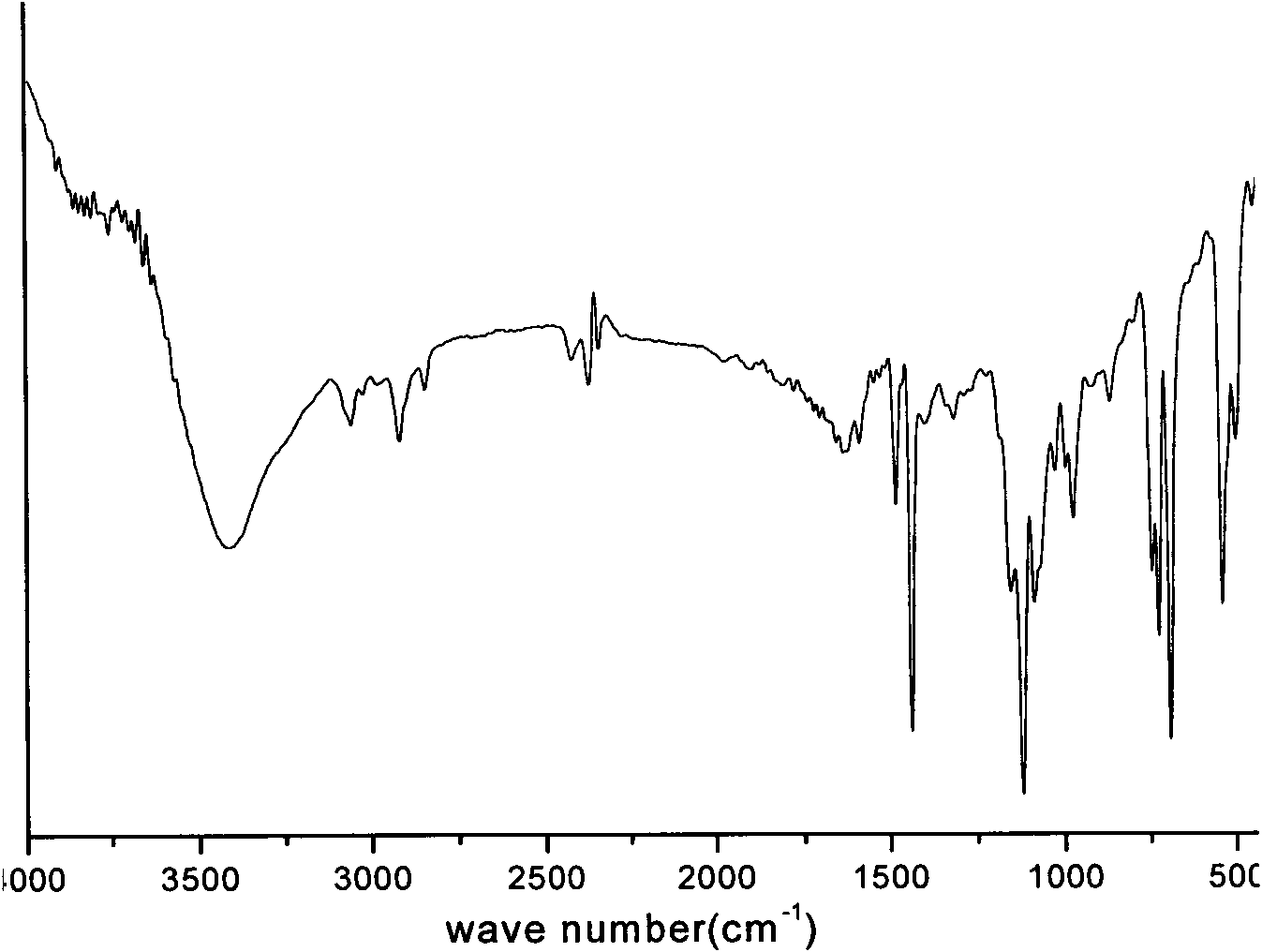

Image

Examples

Embodiment 1

[0031] The structural formula of the organophosphine-based tungsten complex in this embodiment is as follows: [W(OPPh 3 ) 2 ]Cl 6 .

[0032] The preparation method of the organophosphine-based tungsten complex of this embodiment is as follows:

[0033] 1. Take 10g of sodium tungstate hydrate (Na 2 WO 4 ·2H 2 O) In an Erlenmeyer flask, slowly add distilled water at 50℃ and keep stirring until it just dissolves. Under continuous stirring, slowly add concentrated hydrochloric acid until no more yellow precipitate is formed. Add 2ml of concentrated hydrochloric acid, and then continue. Reacted for 8 hours; the precipitate was filtered and washed repeatedly with a large amount of distilled water until the pH value was neutral, and the obtained solid was vacuum dried at 50°C for 4 hours to obtain yellow tungstic acid (H 2 WO 4 ) 6.8g solid powder;

[0034] 2. Weigh 6g of the solid tungstic acid powder obtained in step 1, add 150 mL of concentrated hydrochloric acid under continuous stirrin...

Embodiment 2

[0037] The structural formula of the organophosphine-based tungsten complex in this embodiment is as follows: [W(PPh 3 ) 2 ]Cl 6 .

[0038] The preparation method of the organophosphine-based tungsten complex of this embodiment is as follows:

[0039] 1. Take 12g of hydrated sodium tungstate (Na 2 WO 4 ·2H 2 O) In an Erlenmeyer flask, slowly add distilled water at 60℃ and keep stirring until it just dissolves. Under continuous stirring, slowly add concentrated hydrochloric acid until no more yellow precipitate is formed. Add 2ml of concentrated hydrochloric acid, and then continue. Reacted for 9 hours; the precipitate was filtered and washed repeatedly with distilled water until the pH was neutral. The solid obtained was vacuum dried at 50°C for 4 hours to obtain yellow tungstic acid (H 2 WO 4 ) 8.28g of solid powder.

[0040] 2. Weigh 8 g of the solid tungstic acid powder obtained in step 1, add 160 mL of concentrated hydrochloric acid under continuous stirring, raise the temperatur...

Embodiment 3

[0043] The structural formula of the organophosphine-based tungsten complex in this embodiment is as follows: {W[P(PhC 3 H 7 ) 3 ] 2 }Cl 6 .

[0044] The preparation method of the organophosphine-based tungsten complex of this embodiment is as follows:

[0045] 1. Take 15g of hydrated sodium tungstate (Na 2 WO 4 ·2H 2 O) In an Erlenmeyer flask, slowly add distilled water at 70℃ and keep stirring until it just dissolves. Under continuous stirring, slowly add concentrated hydrochloric acid until no more yellow precipitate is formed. Add 2ml of concentrated hydrochloric acid, and then continue. Reacted for 10 hours; the precipitate was filtered and washed repeatedly with distilled water until the pH value was neutral. The resulting solid was vacuum dried at 50°C for 4 hours to obtain yellow tungstic acid (H 2 WO 4 ) 11g of solid powder.

[0046] 2. Weigh 10g of the solid powder of tungstic acid obtained in step 1, add 158.33mL of concentrated hydrochloric acid under stirring, raise the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com