Polydicyclopentadiene/polystyrene interpenetrating polymer network and preparation method thereof

A polydicyclopentadiene, interpenetrating polymer technology, applied in the polydicyclopentadiene/polystyrene interpenetrating polymer network, the field of preparation of the interpenetrating polymer network, to increase flame retardancy, stretch The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

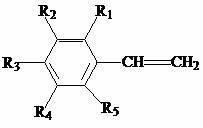

Image

Examples

Embodiment 1

[0024] The polydicyclopentadiene-polystyrene interpenetrating polymer network of this embodiment is composed of the following components in weight percent: 98.99 parts of polydicyclopentadiene, 1 part of styrene and 0.01 part of divinylbenzene.

[0025] The preparation method of polydicyclopentadiene-polystyrene interpenetrating polymer network of the present invention comprises the following steps:

[0026] (1) Dissolve 1 gram of styrene and 0.01 gram of divinylbenzene in 98.99 grams of dicyclopentadiene at 40°C and stir evenly. After the degassing reaction, use nitrogen protection for later use;

[0027] (2) Under the protection of nitrogen, divide the above solution into two parts A and B, and add 0.647 grams of molybdenum catalyst (the amount added is 1 / 1000 of the molar number of dicyclopentadiene) and 0.01 grams of benzene peroxide to part A Formyl initiator; add 1.8 grams of diethylaluminum chloride (20 times the number of moles of the tungsten catalyst in part A) to pa...

Embodiment 2

[0030]The polydicyclopentadiene-polystyrene interpenetrating polymer network of this embodiment is composed of the following components in weight percentage: 88 parts of polydicyclopentadiene, 10 parts of styrene and 2 parts of divinylbenzene.

[0031] The preparation method of polydicyclopentadiene-polystyrene interpenetrating polymer network of the present invention comprises the following steps:

[0032] (1) Add 10 grams of styrene and 2 grams of divinylbenzene to 88 grams of dicyclopentadiene at 50°C and stir evenly. After the degassing reaction, use nitrogen protection for later use;

[0033] (2) Under the protection of nitrogen, divide the above solution into two parts A and B, and add 0.3837 grams of molybdenum catalyst (the addition amount is 1 / 1500 of the molar number of dicyclopentadiene) and 0.12 grams of dicyclopentadiene to part A Cumene initiator; Add 1.07 grams of diethyl aluminum chloride (20 times the molar number of tungsten catalyst in A part) in part B;

...

Embodiment 3

[0036] The polydicyclopentadiene-polystyrene interpenetrating polymer network of this embodiment is composed of the following components in weight percent: 60 parts of polydicyclopentadiene, 35 parts of styrene and 5 parts of divinylbenzene.

[0037] The preparation method of polydicyclopentadiene-polystyrene interpenetrating polymer network of the present invention comprises the following steps:

[0038] (1) Add 35 grams of styrene and 5 grams of divinylbenzene to 60 grams of dicyclopentadiene at 50°C and stir evenly. After the degassing reaction, use nitrogen protection for later use;

[0039] (2) Under the protection of nitrogen, divide the above solution into two parts A and B, and add 0.2615 grams of molybdenum catalyst (the amount added is 1 / 1500 of the molar number of dicyclopentadiene) and 0.4 grams of azobis Isobutyronitrile initiator; Add 0.729 grams of diethyl aluminum chloride (20 times the molar number of tungsten catalyst in A part) in part B;

[0040] (3) Mix p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com