Multi-walled carbon nanotube/barium titanate/polydicyclopentadiene composite material based on front-end ring-opening metathesis polymerization and preparation method thereof

A technology of multi-walled carbon nanotubes and ring-opening metathesis polymerization is applied in the field of MWCNTs/BT/PDCPD composite materials, which can solve the problems of low glass transition temperature and poor dielectric properties, and achieve high dielectric constant and dielectric properties. Low loss and content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

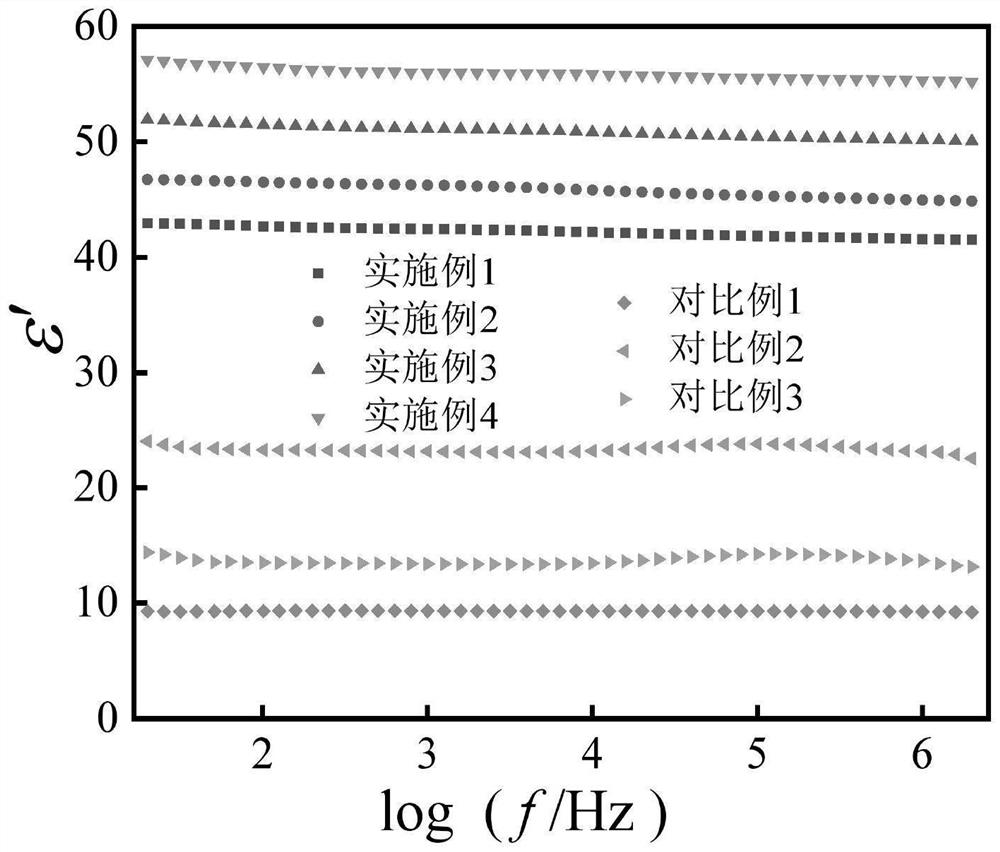

[0048] The MWCNTs / BT / PDCPD composite material in this example contains the following raw materials: DCPD and ENB solution 92.7wt%, wherein the mass ratio of dicyclopentadiene and 5-ethylidene-2-norbornene is 95:5. Catalyst 0.06wt%, inhibitors TBP, TMP, TEP total 0.24wt%. 2wt% for NA-MWCNTs and 5wt% for NA-BT.

[0049] The preparation method of the MWCNTs / BT / PDCPD composite material of the present embodiment comprises the following steps:

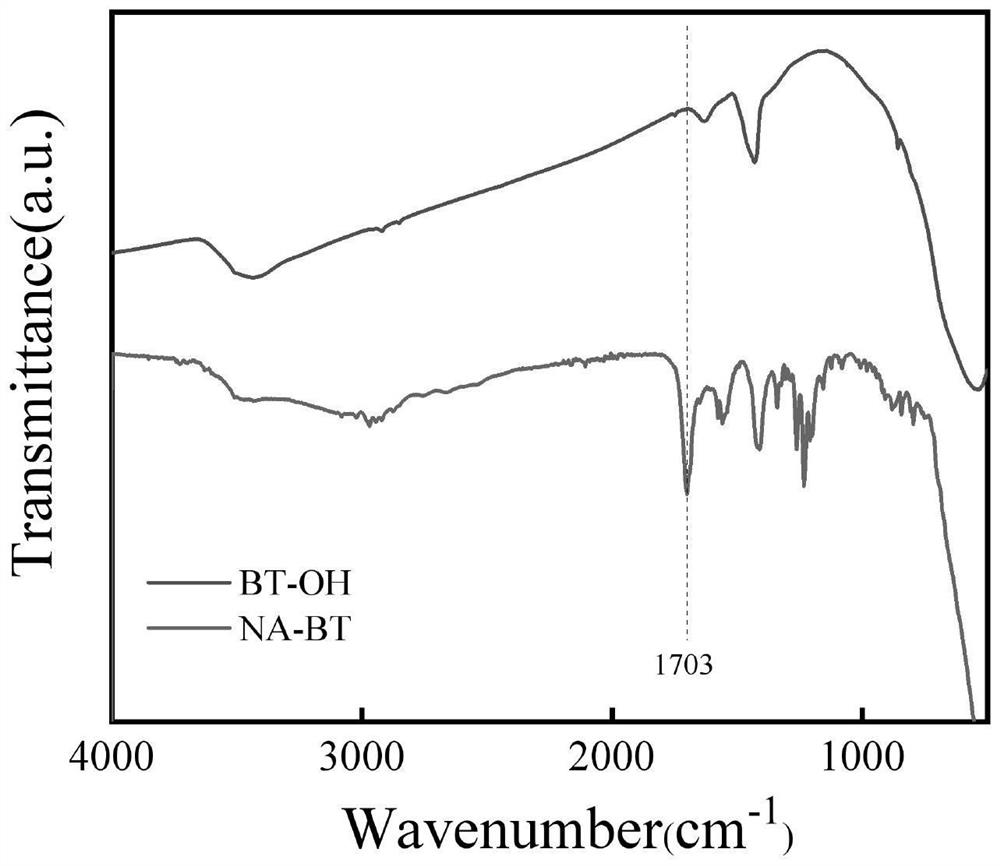

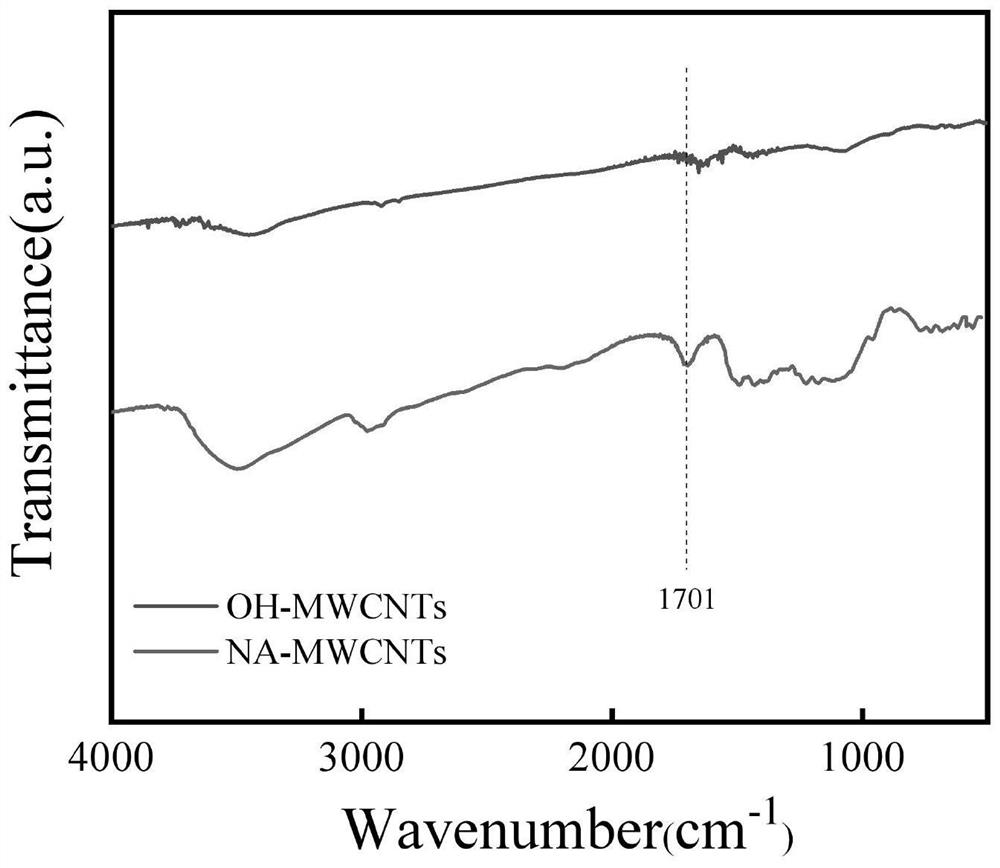

[0050] (1) Add norbornene diacid anhydride to a cleaned three-necked flask, dissolve it with an appropriate amount of toluene, then add hydroxybarium titanate or hydroxycarbon nanotubes, and stir and react at 90°C for 10h. Suction filtration and drying to obtain norbornene-functionalized barium titanate NA-BT or norbornene-functionalized carbon nanotubes NA-MWCNTs.

[0051] (2) Weigh 0.06wt% catalyst GC2 and 0.24wt% inhibitor, dissolve in ENB, then add DCPD, and mix again to obtain DCPD / ENB solution.

[0052] (3) Weigh 2wt% NA-MWCNTs and ...

Embodiment 2

[0055] The MWCNTs / BT / PDCPD composite material in this example contains the following raw materials: DCPD and ENB solution 89.76wt%, wherein the mass ratio of dicyclopentadiene and 5-ethylidene-2-norbornene is 96:4. Catalyst 0.06wt%, inhibitors TBP, TMP, TEP total 0.18wt%. 5 wt% for NA-MWCNTs and 5 wt% for NA-BT.

[0056] The preparation method of the MWCNTs / BT / PDCPD composite material of the present embodiment comprises the following steps:

[0057] (1) Add norbornene diacid anhydride to a cleaned three-necked flask, dissolve it with an appropriate amount of toluene, then add hydroxybarium titanate or hydroxycarbon nanotubes, and stir and react at 90°C for 10h. Suction filtration and drying to obtain norbornene-functionalized barium titanate NA-BT or norbornene-functionalized carbon nanotubes NA-MWCNTs.

[0058] (2) Weigh 0.06wt% catalyst GC2 and 0.18wt% inhibitor, dissolve in ENB, then add DCPD, and mix again to obtain DCPD / ENB solution.

[0059] (3) Weigh 5 wt% of NA-MWCN...

Embodiment 3

[0062] The MWCNTs / BT / PDCPD composite material in this example contains the following raw materials: DCPD and ENB solution 87.7wt%, wherein the mass ratio of dicyclopentadiene and 5-ethylidene-2-norbornene is 95:5. Catalyst 0.06wt%, inhibitors TBP, TMP, TEP total 0.24wt%. NA-MWCNTs is 2wt%, and NA-BT is 10wt%.

[0063] The preparation method of the MWCNTs / BT / PDCPD composite material of the present embodiment comprises the following steps:

[0064] (1) Add norbornene diacid anhydride to a cleaned three-necked flask, dissolve it with an appropriate amount of toluene, then add hydroxybarium titanate or hydroxycarbon nanotubes, and stir and react at 90°C for 10h. Suction filtration and drying to obtain norbornene-functionalized barium titanate NA-BT or norbornene-functionalized carbon nanotubes NA-MWCNTs.

[0065] (2) Weigh 0.06wt% catalyst GC2 and 0.24wt% inhibitor, dissolve in ENB, then add DCPD, and mix again to obtain DCPD / ENB solution.

[0066] (3) Weigh 2wt% NA-MWCNTs and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com