Flame retardant, preparation method as well as modified polydicyclopentadiene and preparation method

A technology of polydicyclopentadiene and dicyclopentadiene is applied in the field of flame retardant materials to achieve the effects of good flame retardant performance, simple process, easy control and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

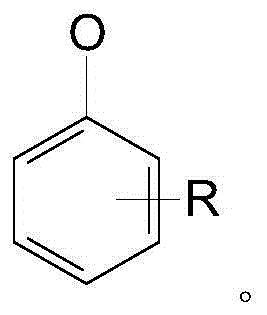

[0040] The chemical structural formula of the present embodiment flame retardant is:

[0041]

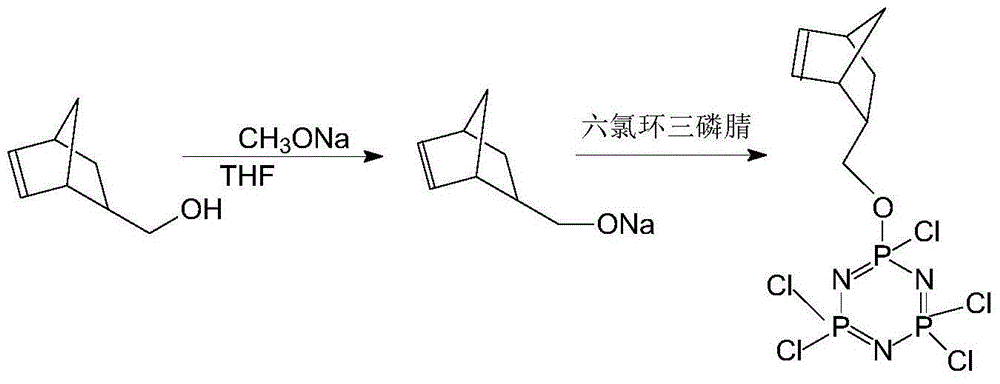

[0042] The preparation method of the flame retardant in this example, the specific operation steps are as follows: under the protection of nitrogen, add norbornene methanol and sodium methoxide of the same amount into 200mL tetrahydrofuran, stir and react at 70°C for 1 hour, and then cool the reaction system After reaching room temperature, add hexachlorocyclotriphosphazene with norbornene methanol and other substances, then heat up to 100°C, react for 3 hours, cool to room temperature, add water to wash until neutral, and dry the organic layer with anhydrous sodium sulfate After filtration, the solvent was distilled off, and the product was mononorbornenylmethoxy pentachlorocyclotriphosphazene with a content of 84%.

[0043] The flame retardant-modified polydicyclopentadiene composite material of this embodiment is obtained by blending and polymerizing dicyclopentadiene and a fl...

Embodiment 2

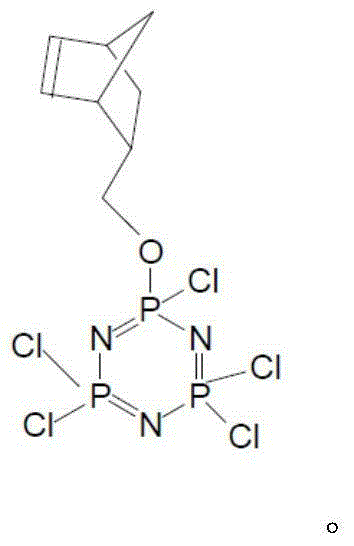

[0049] The chemical structural formula of the present embodiment flame retardant is:

[0050]

[0051] The preparation method of the flame retardant in this example is as follows, and the specific operation steps are as follows: under the protection of nitrogen, add norbornene methanol and sodium methoxide in an equivalent amount to 200ml tetrahydrofuran, and stir and react at 80°C for 2 hours. After cooling to room temperature, add hexachlorocyclotriphosphazene with norbornene methanol and other substances, then heat up to 90°C, react for 5 hours, cool to room temperature, add water to wash until neutral, and wash the organic layer with anhydrous sodium sulfate After drying, filter and distill off the solvent, the product is mononorbornenylmethoxy pentachlorocyclotriphosphazene with a content of 90.5%.

[0052] The flame retardant-modified polydicyclopentadiene composite material in this embodiment is formed by blending and polymerizing dicyclopentadiene and a flame retard...

Embodiment 3

[0058] The chemical structural formula of the present embodiment flame retardant is:

[0059]

[0060]The preparation method of the flame retardant in this example is as follows. The specific operation steps are as follows: under the protection of nitrogen, add norbornene methanol and sodium methoxide in an equivalent amount to 200ml of tetrahydrofuran, stir and react at 90°C for 4 hours, and then react After cooling the system to room temperature, add hexachlorocyclotriphosphazene with norbornene methanol and other substances, then raise the temperature to 80°C, react for 6 hours, cool to room temperature, add water to wash until neutral, and wash the organic layer with anhydrous sulfuric acid After drying with sodium, filter and distill off the solvent, the product is mononorbornenylmethoxy pentachlorocyclotriphosphazene with a content of 93.5%.

[0061] The flame retardant-modified polydicyclopentadiene composite material in this embodiment is formed by blending and poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com