Polydicyclopentadiene composite material and preparation method thereof

A technology of polydicyclopentadiene and dicyclopentadiene is applied in the field of polydicyclopentadiene composite materials, which can solve the problems of resin falling off on the surface of glass fiber reinforced plastics, affecting the environment and human health, and rapidly expanding the damaged area, so as to shorten the processing flow. , Overcome water absorption and mildew, improve processing speed and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

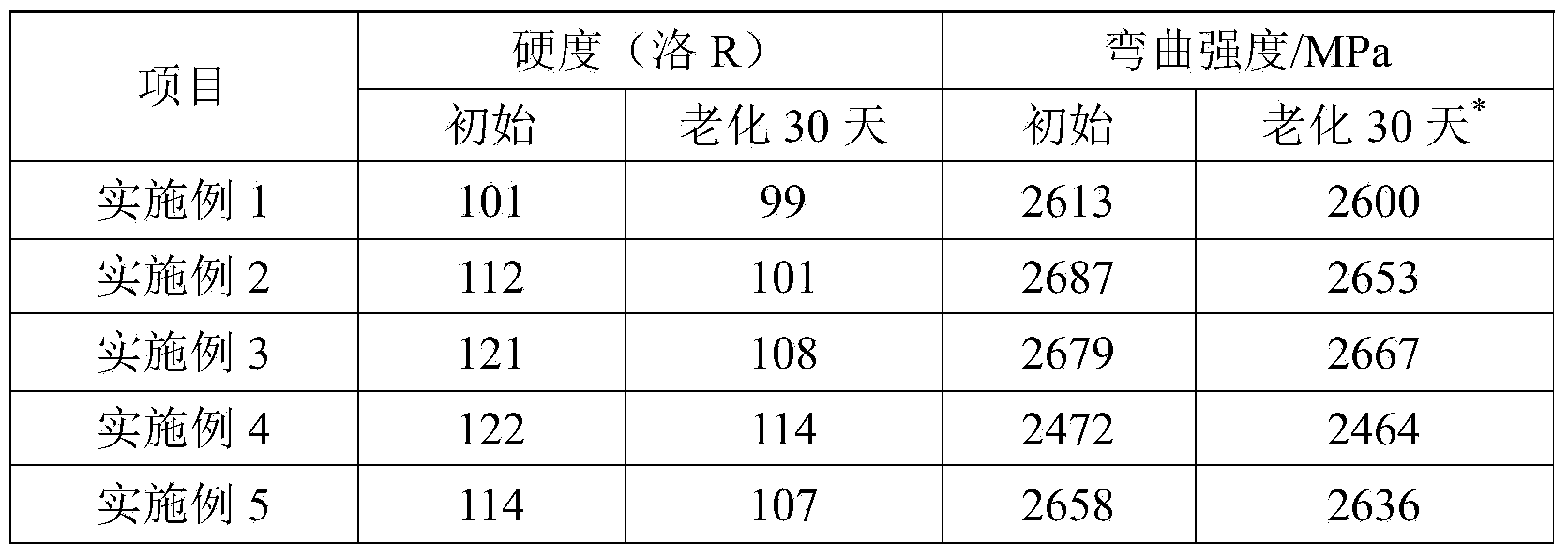

Examples

Embodiment 1

[0036] The polydicyclopentadiene composite material in this example is prepared by reacting the following raw materials: dicyclopentadiene, bis[2,6 di-tert-butyl-4-methylphenoxy] tungsten dichloride and monochlorodi The molar ratio of ethylaluminum is 2000:1:15, the addition amount of 2mm glass fiber, 1500 mesh barite powder, nanometer calcium carbonate powder, 2,6-di-tert-butyl p-cresol and UV-531 is bicyclic 2%, 20%, 10%, 0.5%, 0.1% of the mass of pentadiene.

[0037] The preparation method of polydicyclopentadiene composite material in the present embodiment is:

[0038] (1) Take 50% of the amount from dicyclopentadiene, glass fiber, barite powder, nanometer calcium carbonate powder, 2,6-di-tert-butyl-p-cresol, and UV-531, and di[2,6 Ditert-butyl-4-methylphenoxy] tungsten dichloride mixed under nitrogen protection as component A standby

[0039] (2) Mix the remaining raw materials under nitrogen protection as component B for later use;

[0040] (3) The above-mentioned co...

Embodiment 2

[0043] The polydicyclopentadiene composite material in this example is prepared by reacting the following raw materials: dicyclopentadiene, bis[2,6 di-tert-butyl-4-methylphenoxy] tungsten dichloride and triethyl The molar ratio of aluminum is 3000:1:20, 1mm glass fiber, 2000 mesh molybdenum disulfide, nano calcium carbonate powder, tris(2,4-di-tert-butylphenyl) phosphite, UV-327 added They are 5%, 10%, 7%, 1%, and 1% of the mass of dicyclopentadiene, respectively.

[0044] The preparation method of polydicyclopentadiene composite material in the present embodiment is:

[0045] (1) Take 50% of the amount from dicyclopentadiene, glass fiber, molybdenum disulfide, nanometer calcium carbonate powder, tris(2,4-di-tert-butylphenyl) phosphite, and UV-327, and mix with Bis[2,6-di-tert-butyl-4-methylphenoxy]tungsten dichloride is mixed under nitrogen protection as component A for later use

[0046] (2) Mix the remaining raw materials under nitrogen protection as component B for later...

Embodiment 3

[0050] The polydicyclopentadiene composite material in this example is prepared by reacting the following raw materials: dicyclopentadiene, bis[2,6 di-tert-butyl-4-methylphenoxy] tungsten dichloride and monochlorodi The molar ratio of ethyl aluminum is 4000:1:40, 0.1mm glass fiber, 2500 mesh molybdenum disulfide, nanometer calcium carbonate powder, bis(3,5-di-tert-butyl-4-hydroxyphenyl) sulfide, Tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester and UV-326 are added in amounts of 10%, 10%, 5%, and 1% of the quality of dicyclopentadiene respectively. %, 1%, 3%.

[0051]The preparation method of polydicyclopentadiene composite material in the present embodiment is:

[0052] (1) From dicyclopentadiene, glass fiber, molybdenum disulfide, nanometer calcium carbonate powder, bis(3,5-di-tert-butyl-4-hydroxyphenyl)sulfide, tetrakis(β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, UV-326 respectively take out 50% of the amount, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com