Polymer molecule brush supported catalyst as well as synthesis method and application of catalyst

A technology of supported catalyst and synthesis method, applied in the field of polymer supported catalyst and polymer synthesis, can solve the problems of waste of environment, pollution, cumbersome separation and purification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

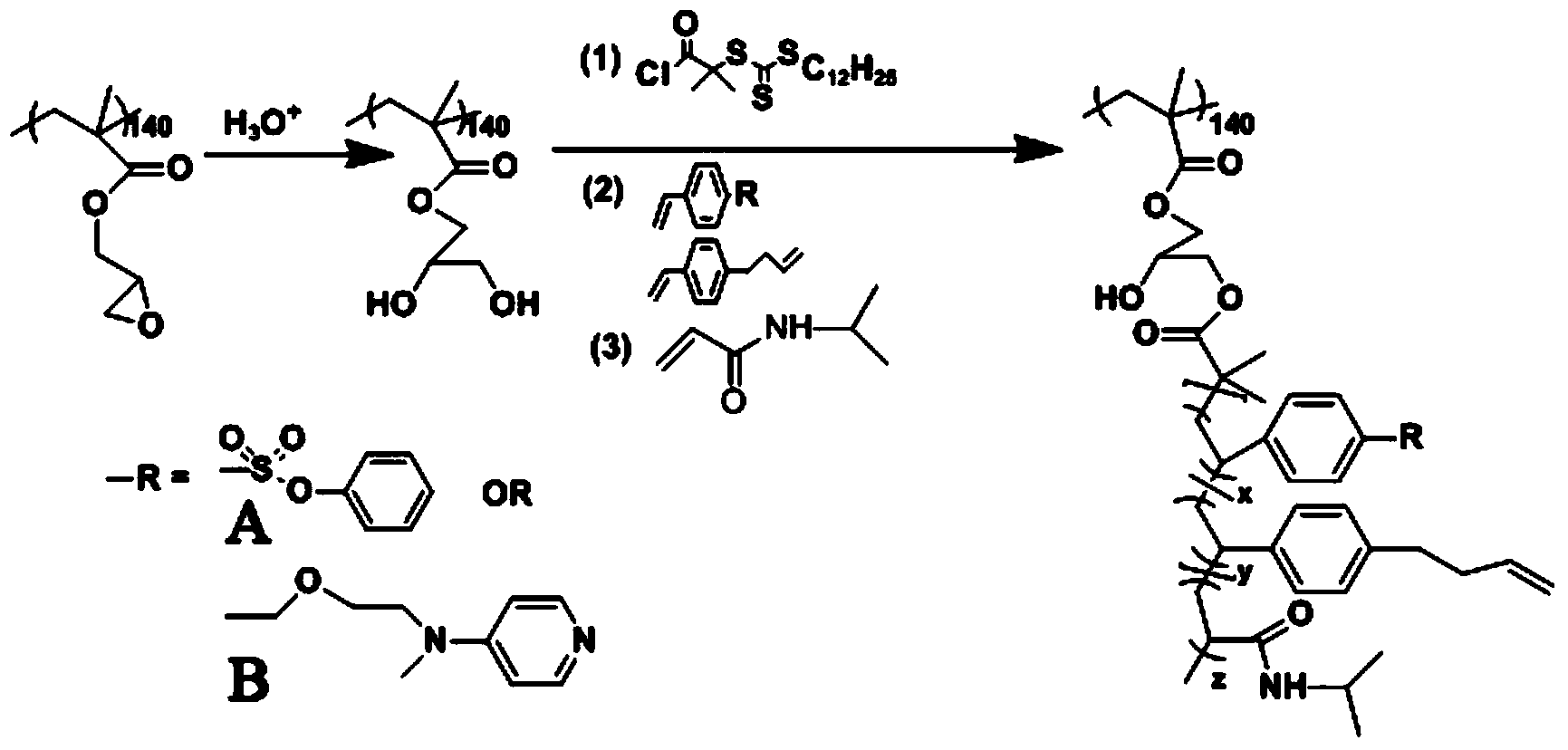

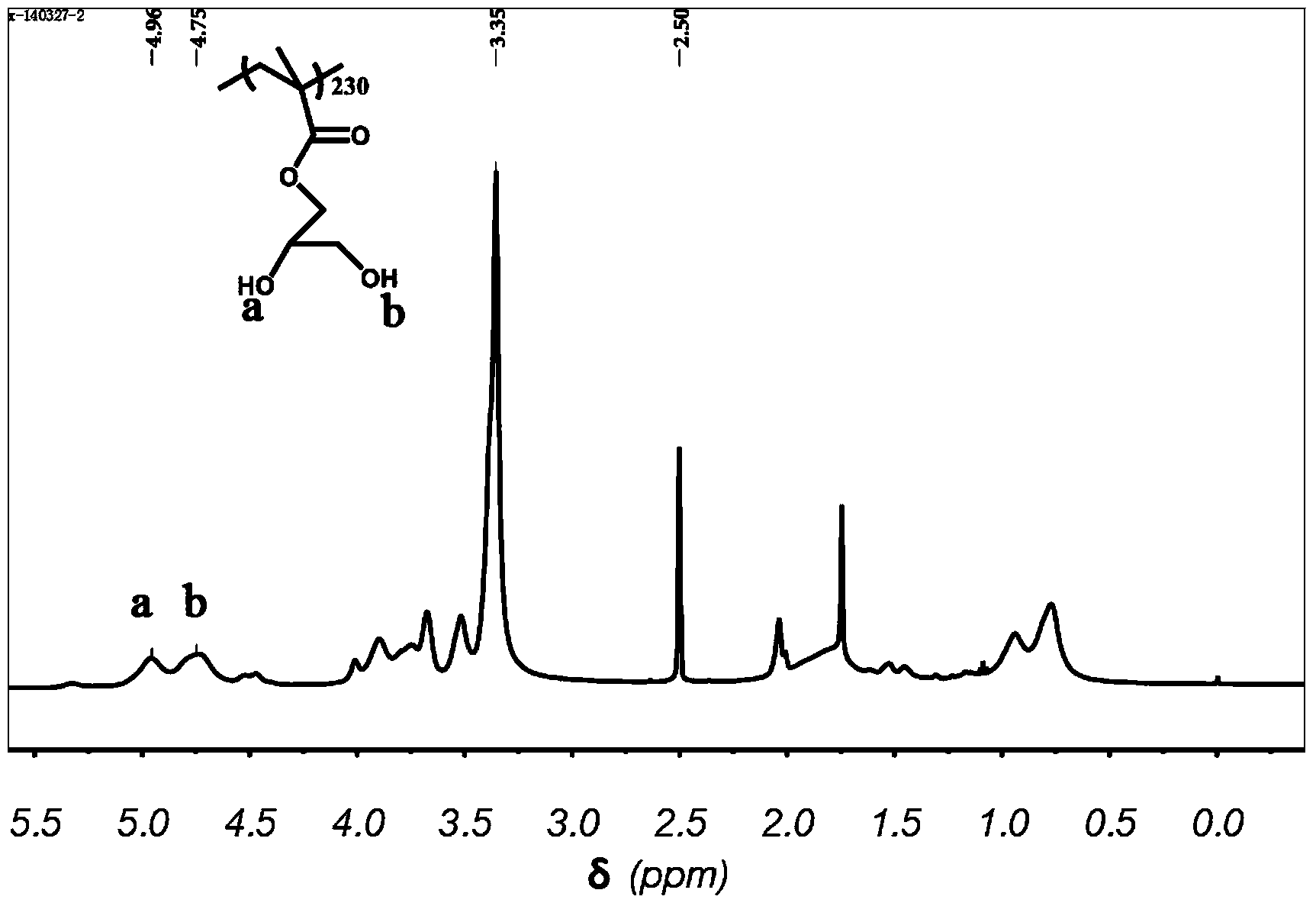

[0032] The synthetic method of the polymer molecular brush of the present invention comprises the following steps:

[0033] (1) Using glycidyl methacrylate (GM) as a monomer, the main chain of polyglycidyl methacrylate (PGM) was synthesized by reversible addition-fragmentation chain transfer polymerization (RAFT), and the main chain of polyglycidyl methacrylate (PGM) was hydrolyzed. The epoxy group is converted into a hydroxyl group; then a RAFT chain transfer agent is installed at the end of the hydroxyl group; then the catalytic functional monomer and 4-butenyl styrene are randomly copolymerized and grafted to the molecular backbone; in order to increase its solubility and increase steric hindrance, and then a layer of N-isopropylacrylamide (NIPAAm) was added to the outside; the precursor of the polymer molecular brush was obtained;

[0034] (2) the molecular brush precursor obtained above is catalyzed and cross-linked with the first-generation Grubbs catalyst; after the cro...

Embodiment 1

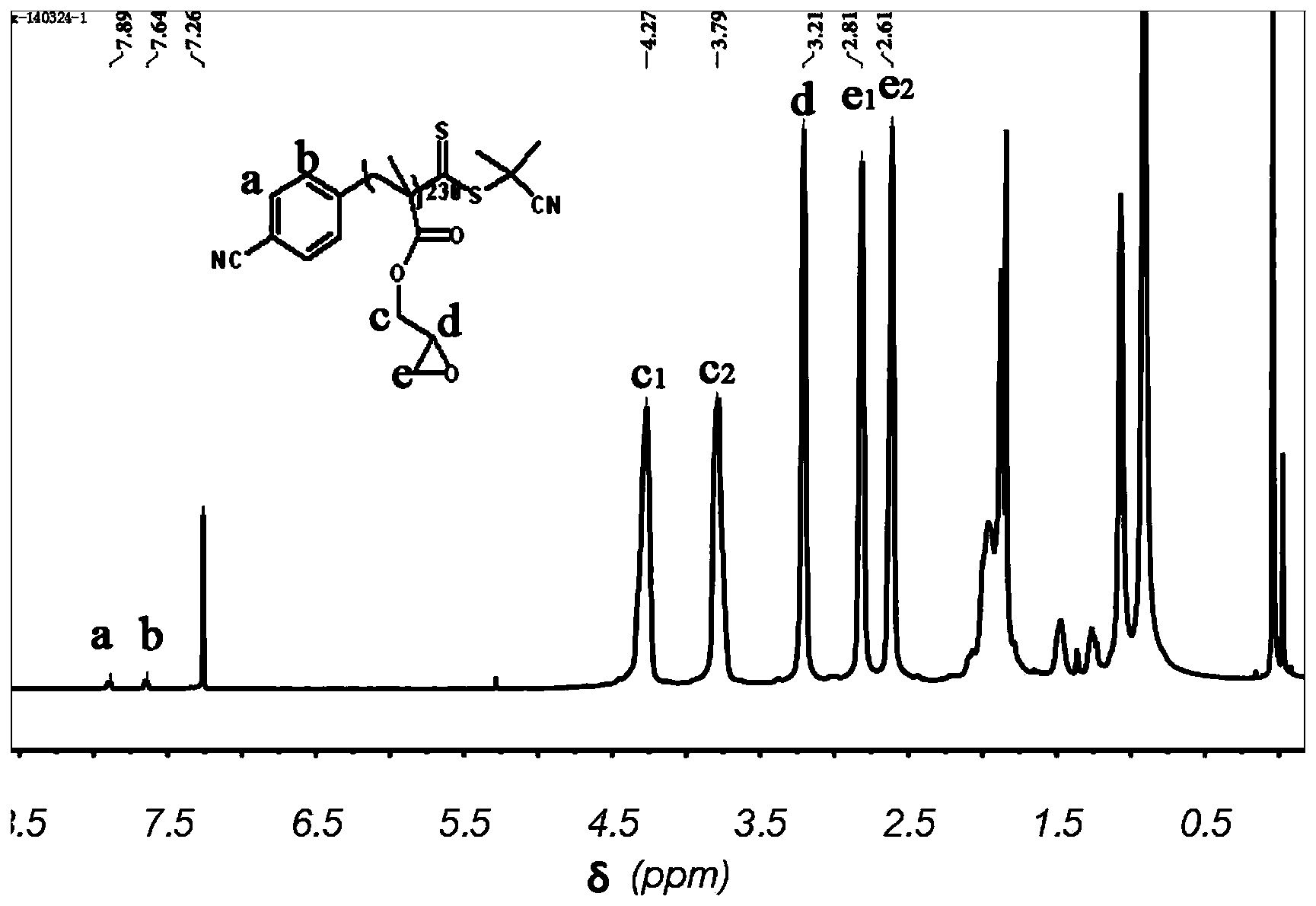

[0051] Example 1: RAFT modification of the main chain

[0052] Add 4.55g RAFT reagent to a dry 100ml round bottom flask This was dissolved by adding 10 ml of dry dichloromethane. With the bubbler connected, slowly add 10 ml of oxalyl chloride (C 2 O 2 Cl 2 ), and reacted for 2h after the addition. After the reaction was completed, the oil was pumped for 6 hours, and the dry dichloromethane and the remaining oxalyl chloride were removed. The hydrolyzed backbone (500 mg) (PGM-OH) was dissolved in dry 40 ml DMF and slowly added to the reaction vial. Reaction for 24h. After the reaction was completed, a yellow precipitate was formed. is the target synthesis product. The DMF was removed by pouring, and the remaining solid was dissolved in dichloromethane and precipitated in methanol to remove impurities such as unreacted RAFT reagent. Repeat three times to ensure that impurities are removed. Finally dried under vacuum for 24h. Obtain the precursor yellow viscous solid 7...

Embodiment 2

[0053] Example 2: Catalytic application of cross-linked organic acid polymer molecular brushes and cross-linked organic base polymer molecular brushes

[0054] M1 (5mg) and M2 (14mg) were dissolved in 0.5ml DMSO, benzaldehyde acetal (4.6mg) and ethyl cyanoacetate (13.5mg) were added to the reaction solution in turn, and 10ulH was added while stirring. 2 O. After heating to 70° C. and reacting for 48 hours, the conversion rate of benzaldehyde acetal was 100%, and the yield of the final product was 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com