Method for preparing polyolefin through metal-catalyzed ring-opening metathesis polymerization

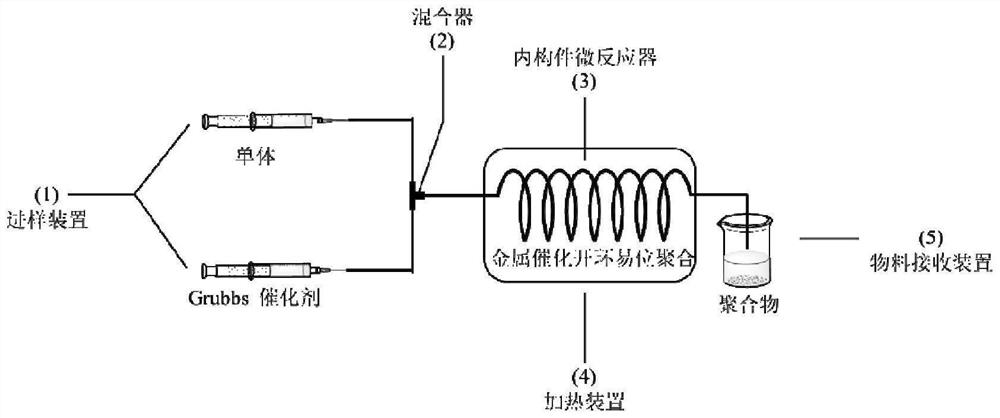

A technology of ring-opening metathesis polymerization and metal catalysis, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve the problems of poor controllability of the polymerization process, weakening Poiseuille flow, increasing Fluid turbulence and other problems can be achieved to reduce the molecular weight distribution index of the product, shorten the mixing time, and realize the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

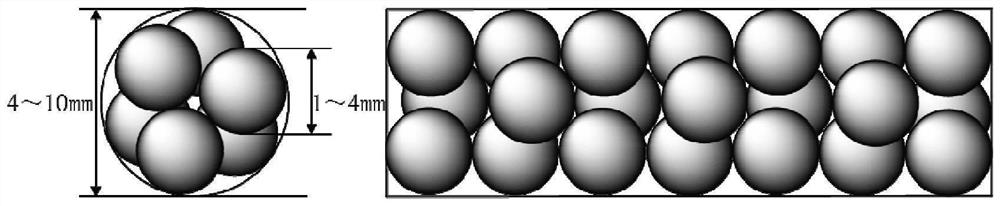

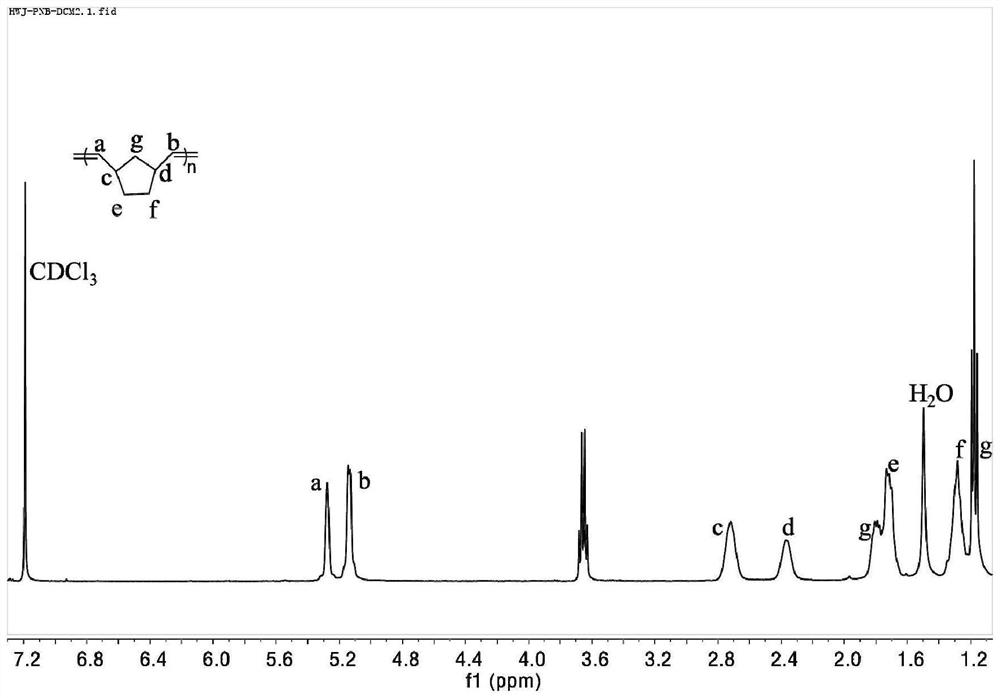

[0041] Fill glass beads with a diameter of 2mm into a glass reaction tube with an inner diameter of 4.00mm, so that the retention volume is 4.00mL; use a microchannel tube with an inner diameter of 1mm and a length of 400mm to connect the syringe and the T-type mixer (the retention volume is 0.31 mL), the T-type mixer is connected to the microreactor of the internal member, and a microchannel tube with an inner diameter of 1 mm and a length of 636 mm is used to connect the receiving device (the retention volume is 0.5 mL). Flush the pipes with tetrahydrofuran solvent that has been re-evaporated and dried. Add 2.5mmol (235.4mg) norbornene and 10mL tetrahydrofuran to two 50mL Schlenk round-bottomed flasks after high-temperature baking to make monomer solution A; and 50μmol (42.44mg) Grubbs second-generation catalyst and 10mL tetrahydrofuran Catalyst solution B, after shaking and mixing, move it into two syringes A and B in the material sampling device respectively. Set the inje...

Embodiment 2

[0043]Fill the quartz beads with a diameter of 1mm into the PTFE reaction tube with an inner diameter of 4.00mm, so that the retention volume is 4.00mL; use a microchannel tube with an inner diameter of 1mm and a length of 400mm to connect the syringe and the T-type mixer (the retention volume is 0.31 mL), the T-type mixer is connected to the microreactor of the internal member, and a microchannel tube with an inner diameter of 1 mm and a length of 636 mm is used to connect the receiving device (the retention volume is 0.5 mL). Flush the pipes with tetrahydrofuran solvent that has been re-evaporated and dried. Add 2.5mmol (235.4mg) norbornene and 10mL tetrahydrofuran to two 50mL Schlenk round-bottomed flasks after high-temperature baking to make monomer solution A; and 50μmol (42.44mg) Grubbs second-generation catalyst and 10mL tetrahydrofuran Catalyst solution B, after shaking and mixing, move it into two syringes A and B in the material sampling device respectively. Set the...

Embodiment 3

[0045] Fill ceramic beads with a diameter of 1mm into a rubber reaction tube with an inner diameter of 4.00mm, so that the retention volume is 40.0mL; use a microchannel tube with an inner diameter of 1mm and a length of 400mm to connect the syringe and the T-type mixer (the retention volume is 0.31 mL), the T-type mixer is connected to the microreactor of the internal member, and a microchannel tube with an inner diameter of 1 mm and a length of 636 mm is used to connect the receiving device (the retention volume is 0.5 mL). Flush the pipes with tetrahydrofuran solvent that has been re-evaporated and dried. Add 12.5mmol (1177.0mg) norbornene and 50mL tetrahydrofuran into two 50mL Schlenk round-bottomed flasks after high-temperature baking respectively to make monomer solution A; Form catalyst solution B, shake and mix well, and then move into two syringes A and B in the material sampling device respectively. Set the injection flow rate of the sampling device A and B to 4mL / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com