Patents

Literature

33results about How to "Molecular weight distribution index is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-solid hydroxyl fluorine-containing acrylic resin and preparation method thereof

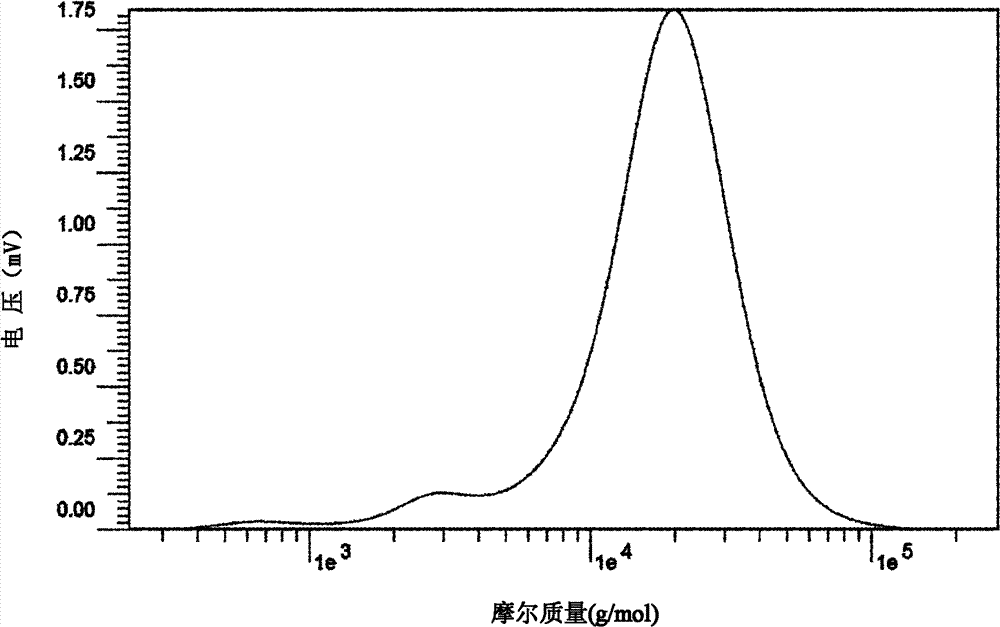

The invention relates to high-solid hydroxyl fluorine-containing acrylic resin and a preparation method thereof. The high-solid hydroxyl fluorine-containing acrylic resin comprises the following components in parts by weight: 10-25 parts of fluorine-containing acrylic ester monomer, 10-30 parts of hydroxyl group-containing acrylic ester monomer, 5-20 parts of methyl acrylic alkyl ester monomer, 5-15 parts of acrylic alkyl ester monomer, 0.3-6 parts of initiator, 0.2-4 parts of chain transfer and 30-50 parts of solvent. According to the hydroxyl fluorine-containing acrylic resin, the solid content reaches up to 75-90 percent, the viscosity is only 900-3,000 mPa.s, the number-average molecular weight is 1,200-6,000, and the molecular weight distribution index is 1.4-2.5; and the resin has the advantages of superior performance, high transparency, no odor of mercaptan, low VOC (Volatile Organic Compound) content, a fluorine carbon group included on a polymer chain and superior corrosion resistance of the resin and can be applied to the fields such as heavy anticorrosive coatings, marine antifouling coatings, aircraft surface coatings, anti-doodling coatings, exterior wall coatings of high weathering resistance and the like.

Owner:SOUTHEAST UNIV

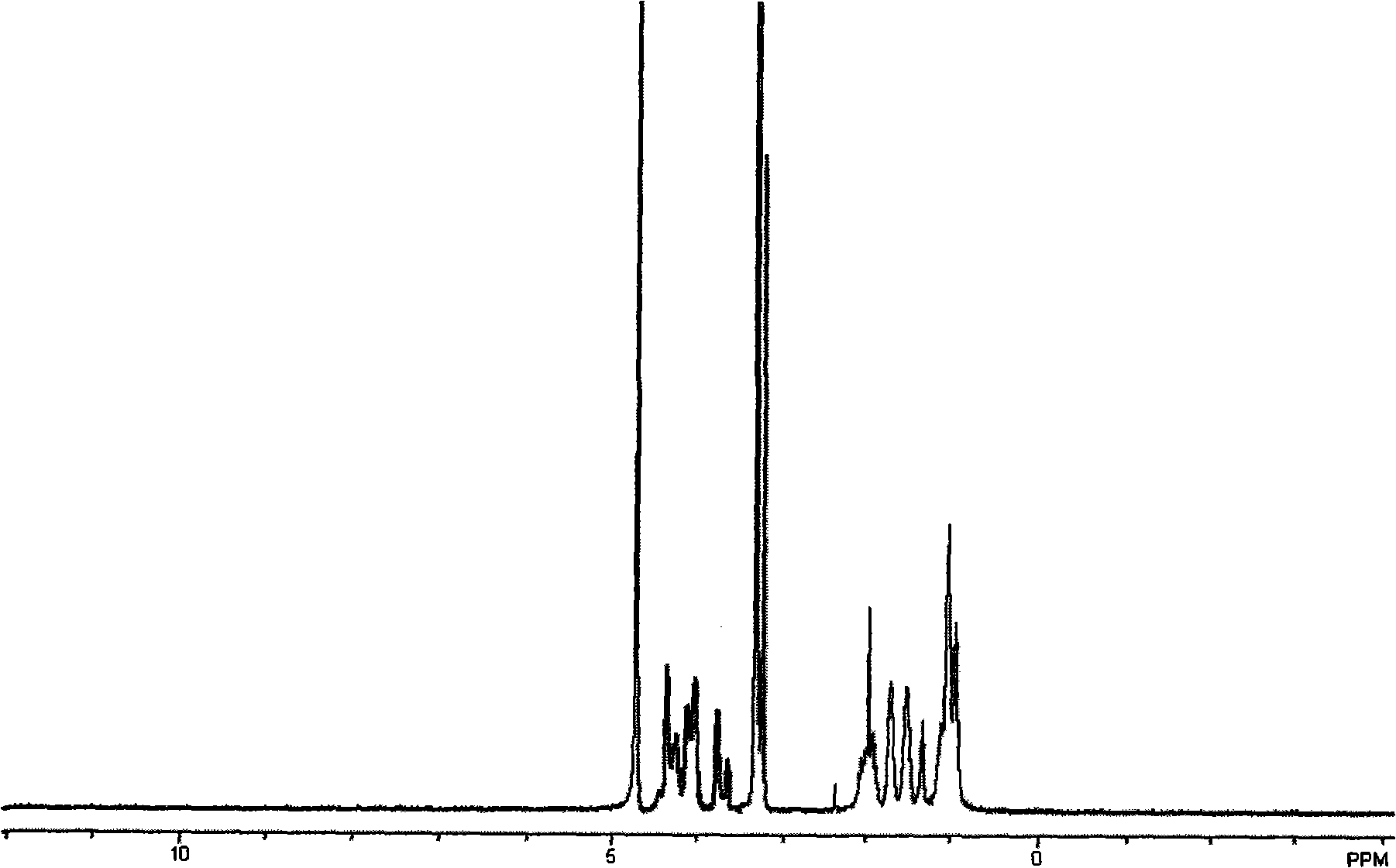

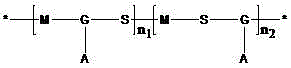

Biocompatibile monodisperse nano polymer carrier and its preparation and medicine-carrying method

InactiveCN101259279AGood biocompatibilityGood blood compatibilityOrganic active ingredientsPharmaceutical non-active ingredientsPhosphorylcholineCarrier system

The invention relates to a monodisperse nano-polymer carrier with biological compatibility and a method for preparation and carrying drug thereof. Firstly, a reversible addition fragmentation chain transfer (RAFT) polymerization method is used for preparing amphiphilic block copolymers with smaller polydispersity index, wherein the hydrophilic segment is methylacryoyloxyethyl phosphorylcholine (MPC) and the hydrophobic segment is n-butyl methacrylate (BMA). Then through the method of solvent evaporation, the amphiphilic block copolymers are used for preparing nano-polymer micelle, drugs are encapsulated in the micelle through physical action, thus obtaining the monodisperse nano-polymer carrier system with good biological compatibility.

Owner:SOUTHEAST UNIV

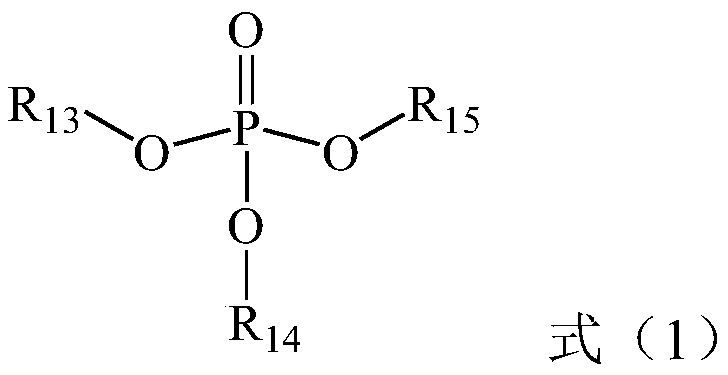

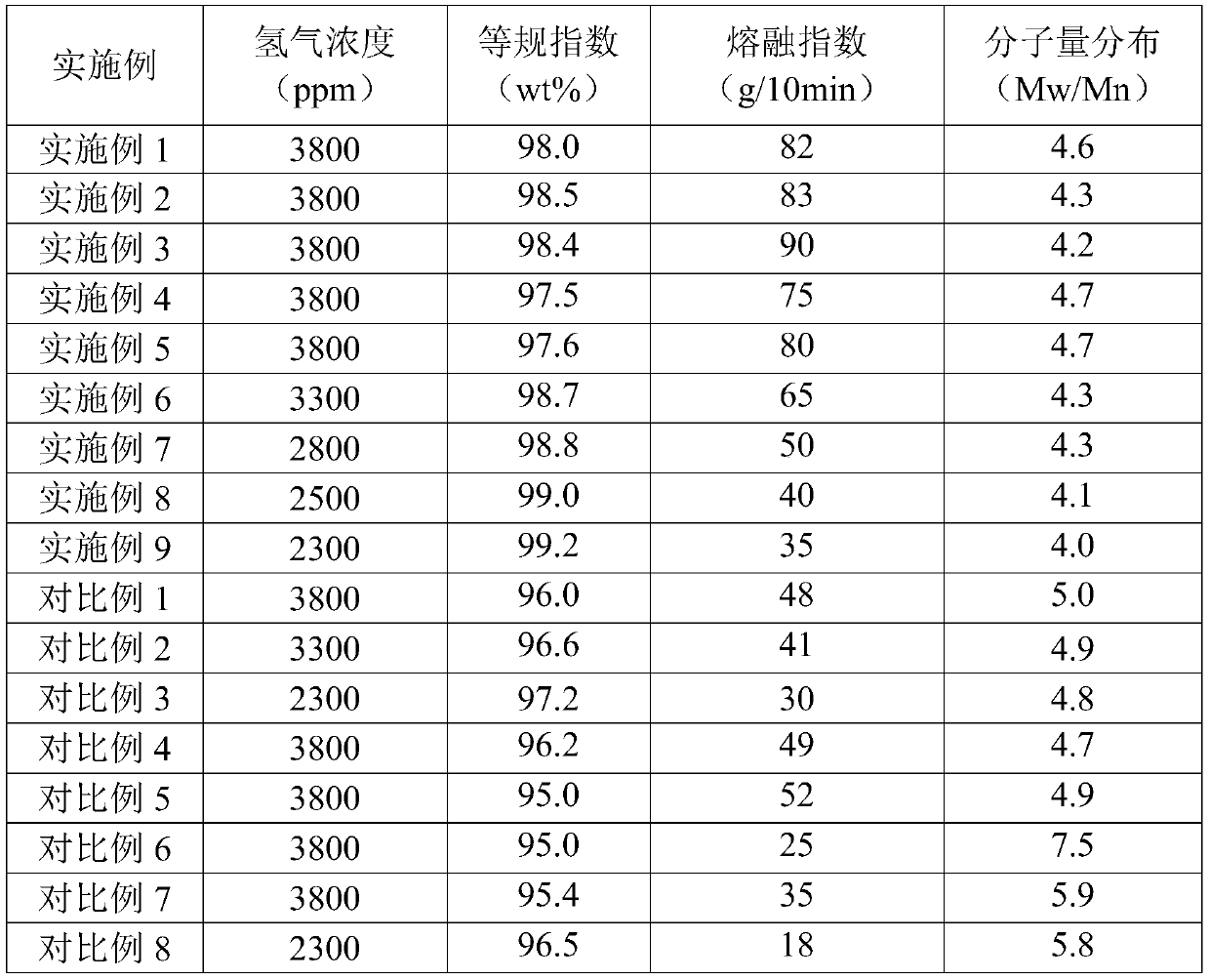

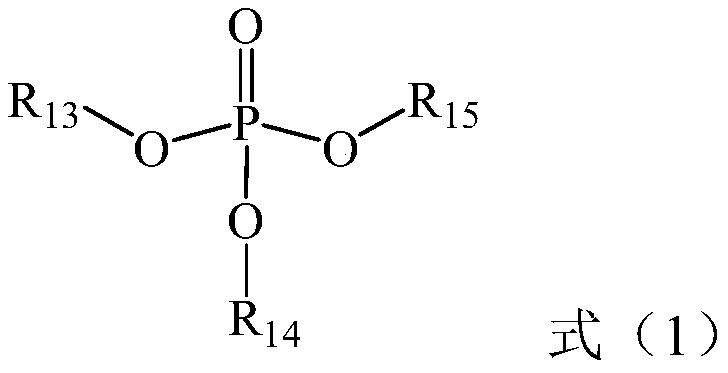

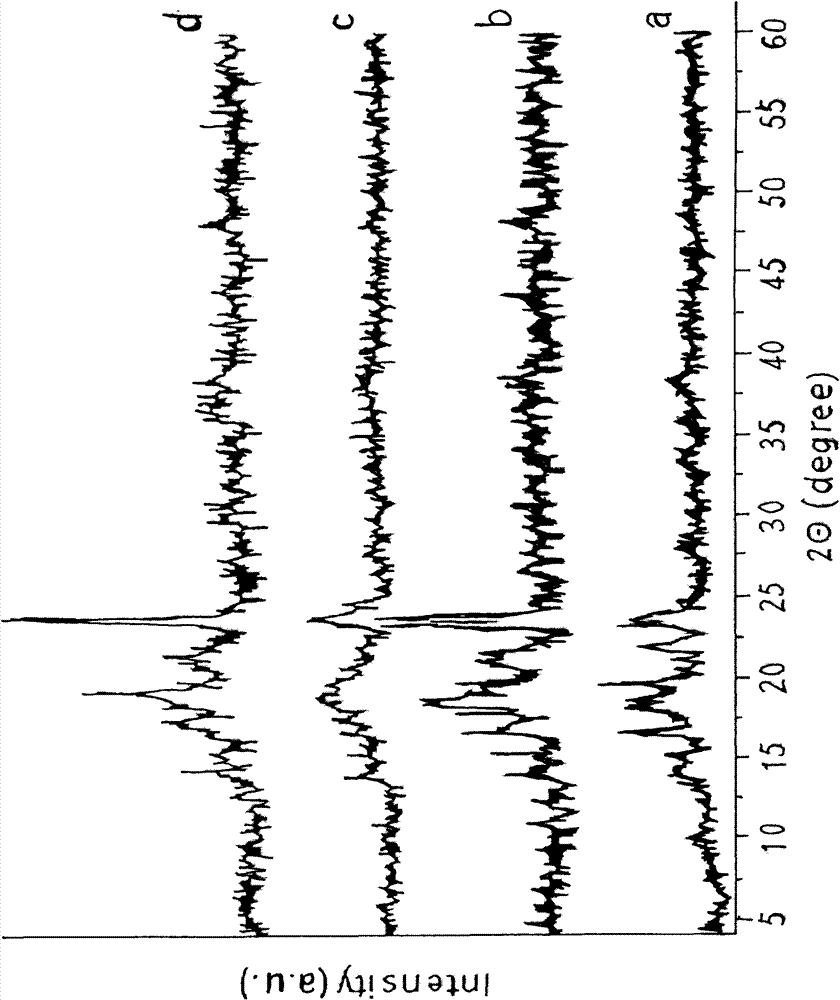

Polypropylene, preparation method and applications thereof

ActiveCN107629155AHigh isotactic indexHigh melt flow indexMonocomponent polypropylene artificial filamentNon-woven fabricsPolymer scienceElectron donor

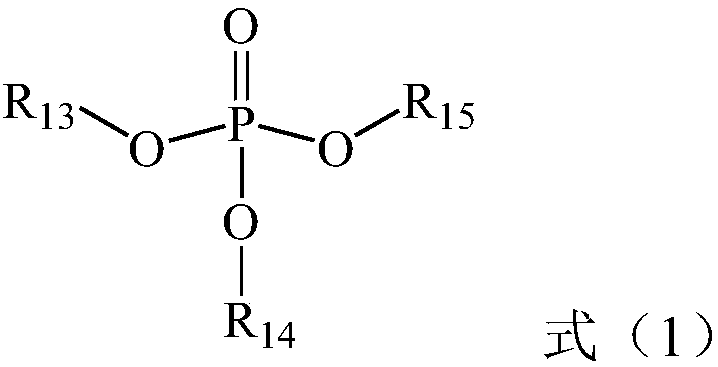

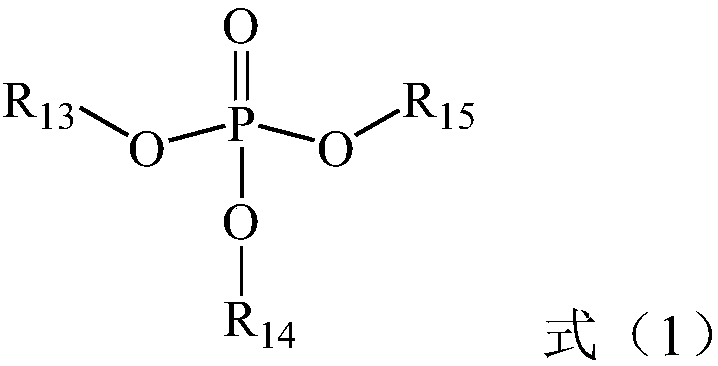

The invention relates to the field of olefin polymerization, and particularly provides polypropylene, a preparation method and applications thereof, wherein the polypropylene has a melt flow index MFRof more than 30 g / 10 min, has an isotactic index of 96-99.5 wt%, and has a molecular weight distribution index MW / Mn of 3-5.5. The preparation method comprises: polymerizing propylene in the presenceof a catalyst under an olefin polymerization condition to obtain a polypropylene product, wherein the catalyst contains a catalyst component, an alkyl aluminum compound, and optionally an external electron donor, the catalyst component contains the product obtained by carrying out a reaction on a magnesium source, a titanium source and an internal electron donor, the internal electron donor contains a phosphate compound and a diether compound, and the phosphorus content (calculated as the phosphorus element) in the catalyst component is not more than 0.06 wt%. According to the present invention, the polypropylene integrates characteristics of high isotactic index, high melt flow index and narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

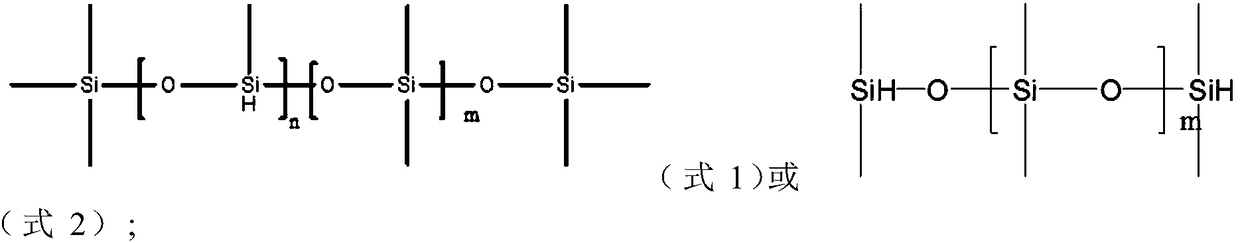

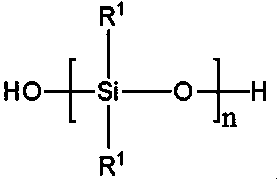

Preparation method of graft modified silicone oil

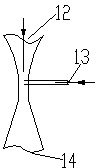

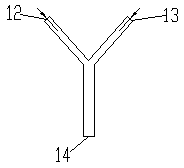

InactiveCN108178834AMolecular weight distribution index is smallSolve the problem of molecular weight too broadMicroreactorHydrogen

The invention relates to a preparation method of graft modified silicone oil. Low-hydrogen silicone oil, allyl polyether, a catalyst and a buffering agent are introduced into a microreactor and subjected to a reaction at 60-160 DEG C under 0-20 bar for 20-1000 s, and the graft modified silicone oil is prepared. By means of the improved preparation method, content of residual monomers is reduced to5% or lower, the problem of too wide molecular weight of a polymer is solved, polydispersity index of the polymer is smaller than 1.2, reaction time is shortened substantially, and side effects are avoided effectively. The production process is simple to operate, low in energy consumption and environmentally friendly, product quality is improved, and little waste is produced.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

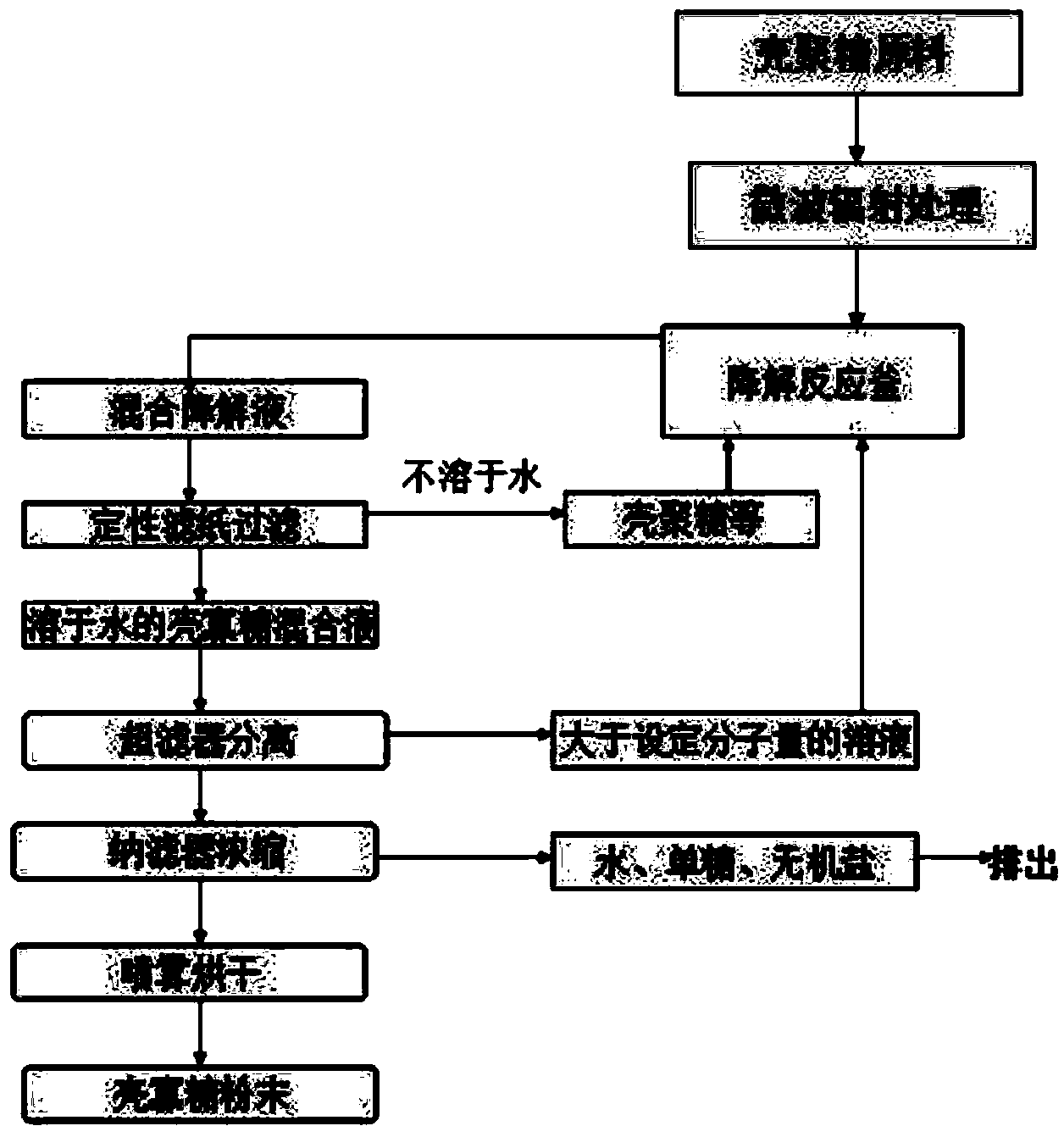

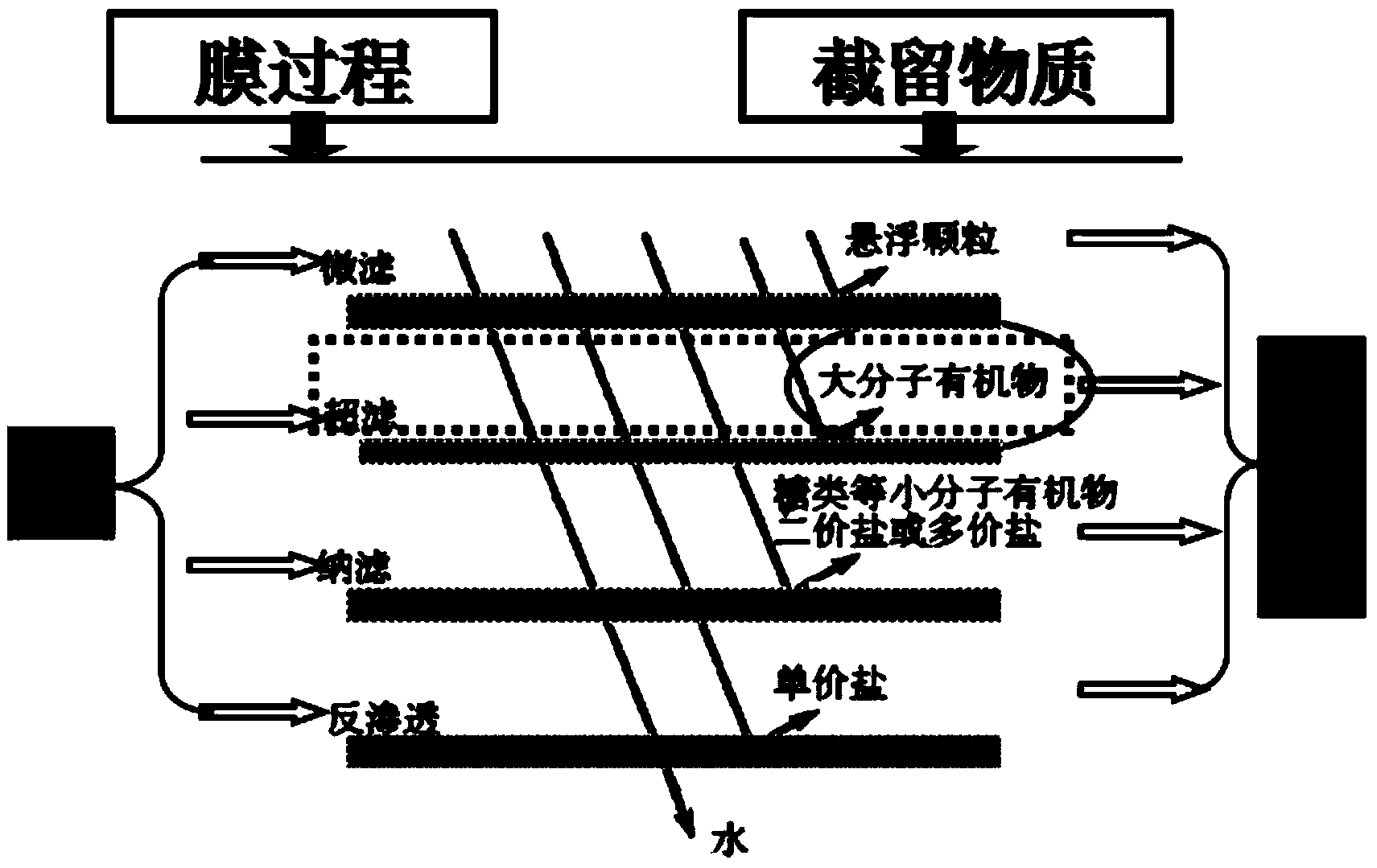

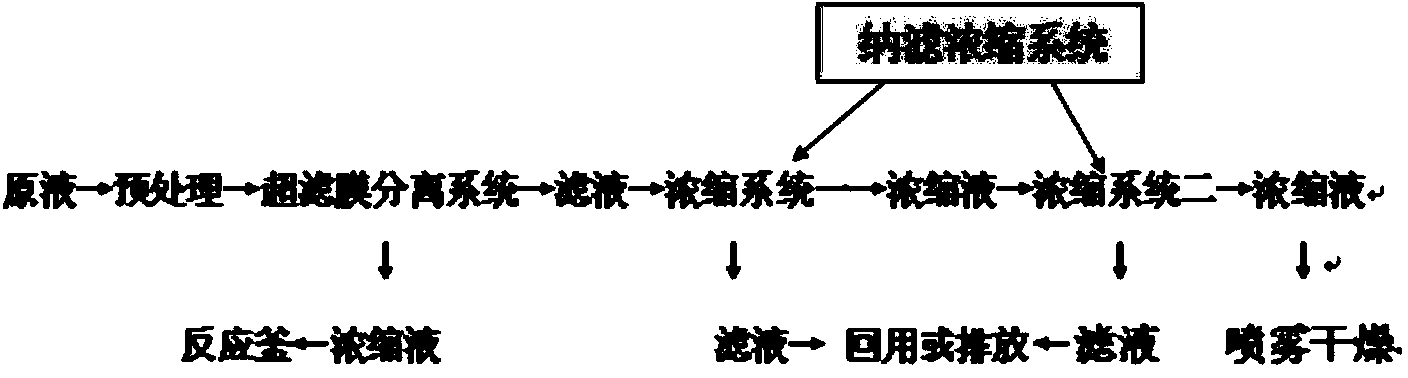

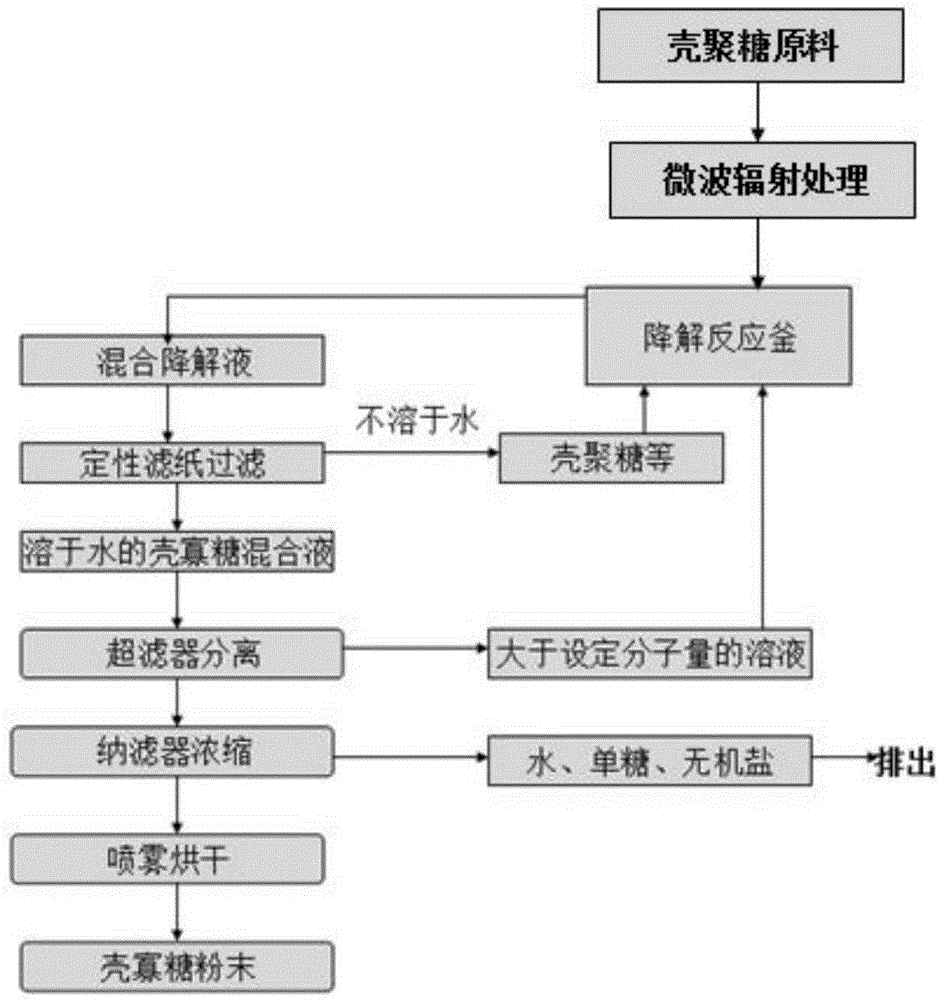

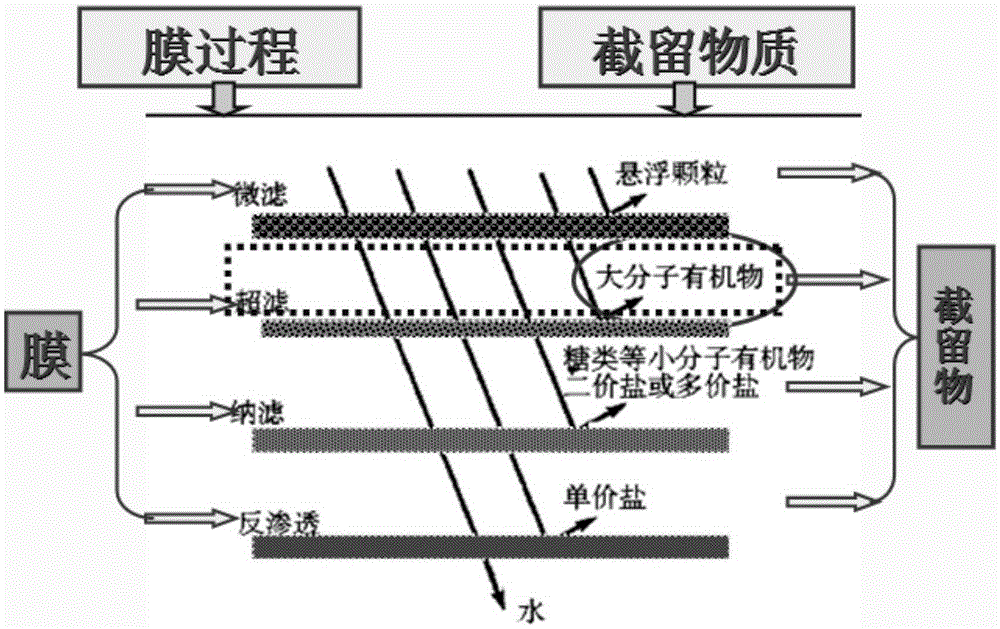

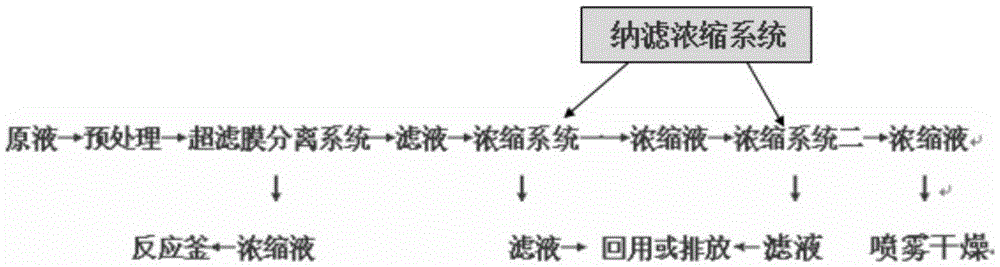

Method for preparing water-soluble chitosan oligosaccharide by adopting ultrafiltration and nanofiltration

ActiveCN103641936AImprove degradation efficiencyHeating fastSugar derivativesSugar derivatives preparationUltrafiltrationSeparation technology

The invention relates to a method for preparing water-soluble chitosan oligosaccharide by adopting ultrafiltration and nanofiltration. The method comprises the following steps: (1) preparing a chitosan oligosaccharide solution by using microwave hydrogen peroxide to perform compound degradation on chitosan; (2) separating out an active oligosaccharide concentrated solution by adopting an ultrafiltration and nanofiltration separation technology; (3) performing spray drying to obtain a chitosan oligosaccharide powder finished product. According to the method provided by the invention, the integrated production of reaction and separation of the finished product is realized, and the secondary degradation of active oligosaccharide is prevented. As the process realizes continuous operation, no other reaction byproducts are generated in the production process, and no pollutants are produced; compared with the preparation method in the prior art, the method has the advantages of advanced production process, simple generation process steps, low investment in production facilities, low cost, environmental friendliness, energy saving, and capability of rapidly realizing industrial production.

Owner:上海长欧生物科技有限公司

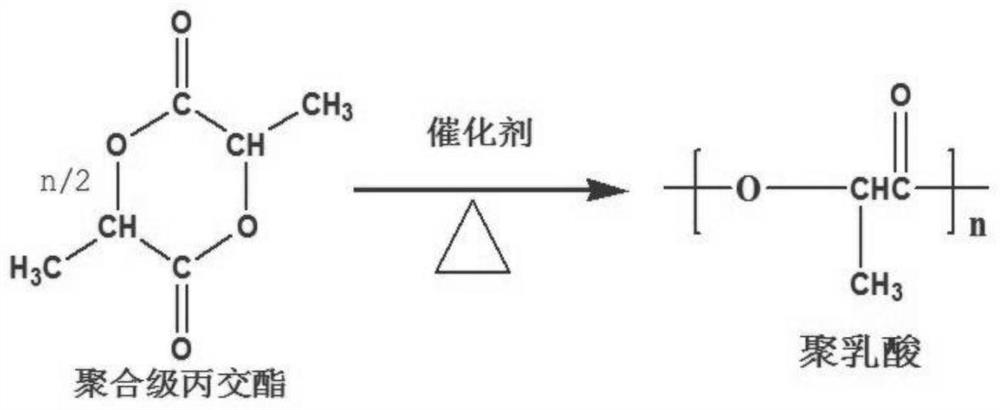

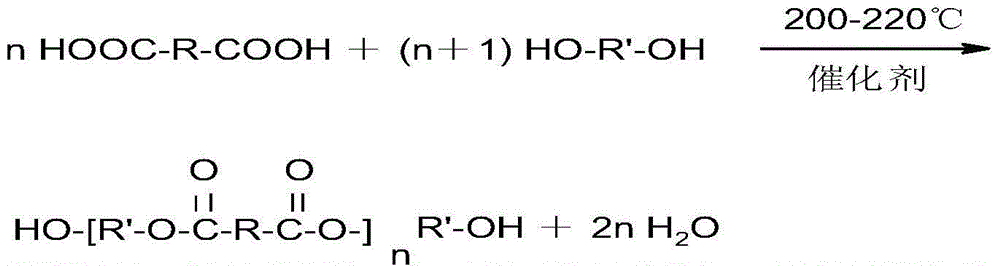

Preparation method of medical biodegradable polymer material polylactate geycollic acid

ActiveCN110283305AAdjustable weight average molecular weightShort reaction timeBiodegradable polymerMonomer

The invention provides a preparation method of medical biodegradable polymer material polylactate geycollic acid (PLGA). A mass polymerization method is adopted for manufacturing the polylactate geycollic acid (PLGA), the production technology is simple, conditions needed by the reaction are low, the reaction speed is high, and the reaction time is short; a catalytic system adopting an organic metal compound as a main catalyst and adopting a substance containing reactive hydrogen as an initiator is adopted as an efficient catalytic system, the reaction time is shorter compared with a single catalyst, the weight-average molecular weight of the product is adjustable, the lowest molecular weight distribution index can reach 1.40, the catalytic activity is high, and the PLGA is non-toxic basically; the reaction product is precipitated three times, unreacted monomers and low-molecular-weight by-products can be removed, the molecular weight distribution index is lowered, and the product purity is improved.

Owner:SHANDONG GUYUCHUN BIOTECHNOLOGY CO LTD

Preparation method of acrylonitrile copolymer spinning solution with low molecular weight distribution

ActiveCN103014894AMolecular weight distribution index is smallQuality improvementMonocomponent synthetic polymer artificial filamentSpinning solutions preparationPolymer scienceAcrylonitrile

The invention discloses a preparation method of an acrylonitrile copolymer spinning solution with low molecular weight distribution. According to the invention, in a solution polymerization process between acrylonitrile monomers and comonomers, the weight-average molecular weight and number-average molecular weight of a copolymer are regulated in a continuous or intermittent cooling manner so as to reduce the molecular weight distribution index of the copolymer. Compared with other methods, the preparation method is simple and feasible and is stronger in process operability, the molecular weight distribution index of an acrylonitrile copolymer obtained according to the method can be controlled to be 2.3-2.8, and an acrylonitrile copolymer solution can be used as a high-performance polyacrylonitrile-based carbon fiber spinning solution after residual monomers and air bubbles are removed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Modified (methyl) acrylate resin and preparation method

The invention discloses modified (methyl) acrylate resin. The resin contains a (methyl) acrylate chain link, an unsaturated double bond and carboxylic group, an unsaturated double bond and epoxy group and an organic silicon group containing double bonds. The modified (methyl) acrylate resin can be solidified through various methods, has the characteristics of high hardness, high toughness, no adhesion, strong adhering force, good wear resistance and the like, and can be applied to fields such as coating, ink and adhesive. The invention further relates to a preparation method of the material.

Owner:CHINA LUCKY FILM CORP +1

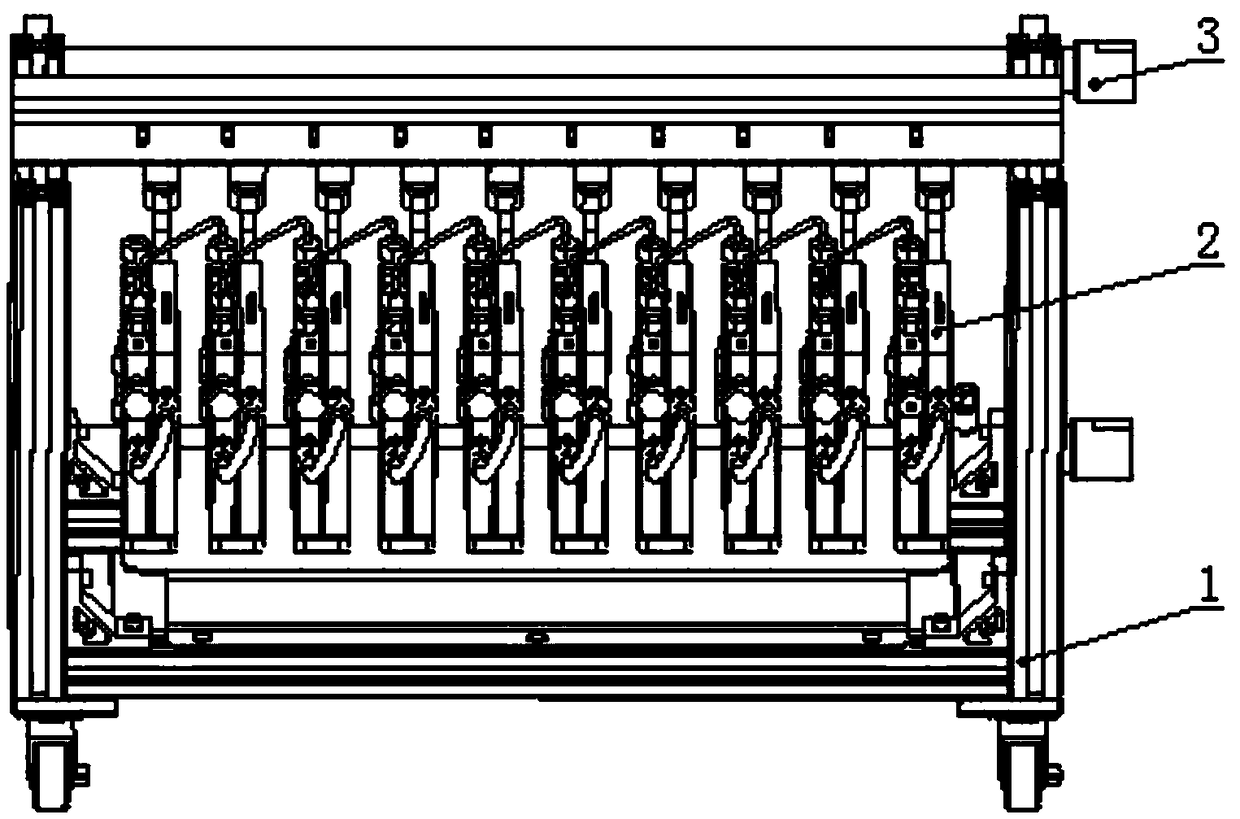

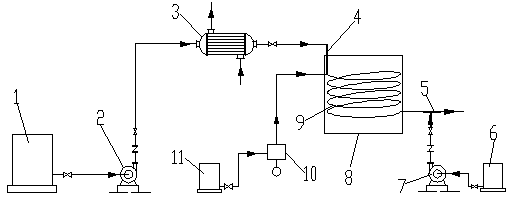

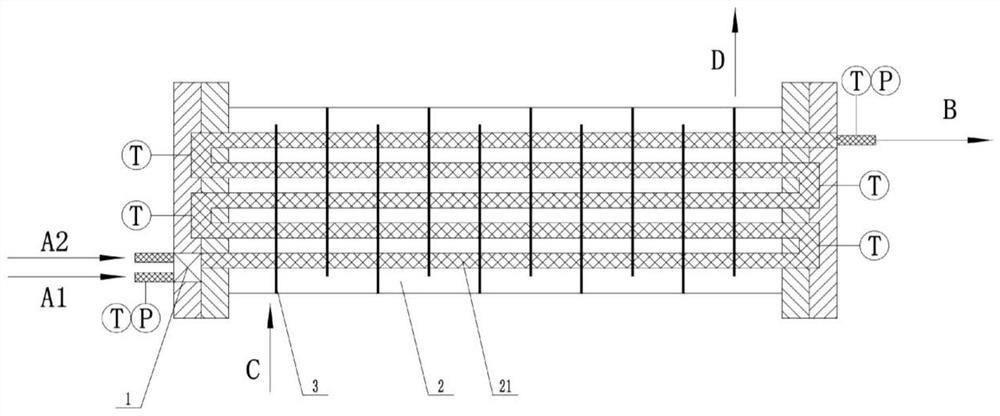

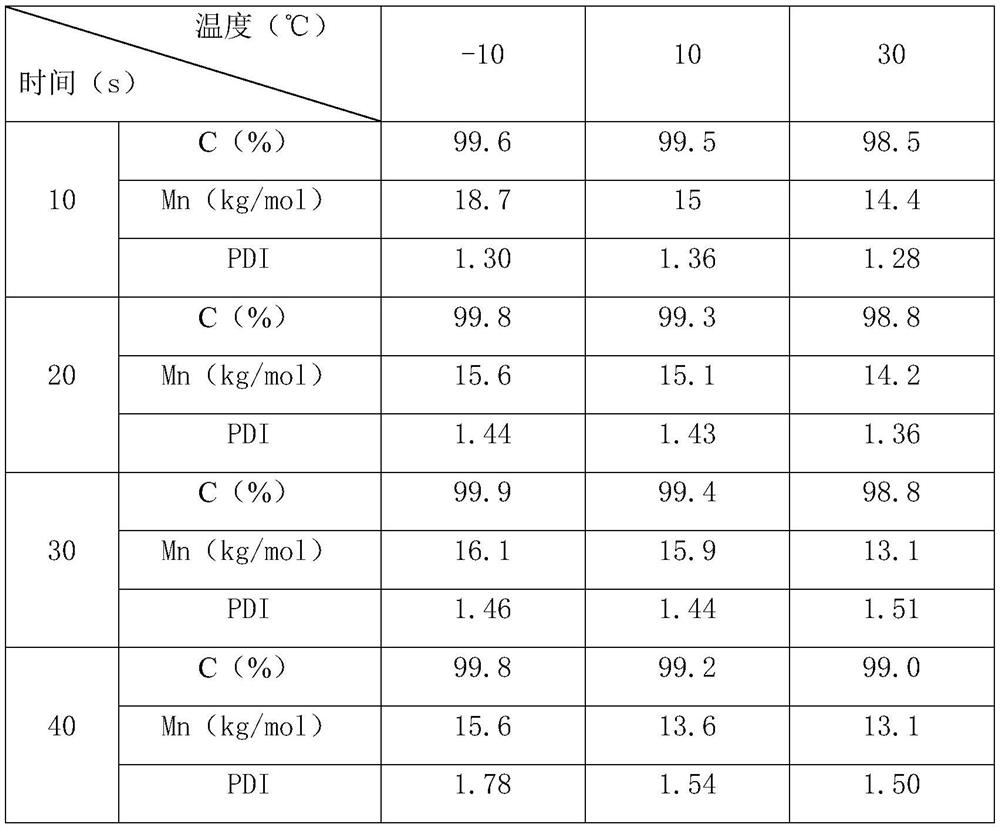

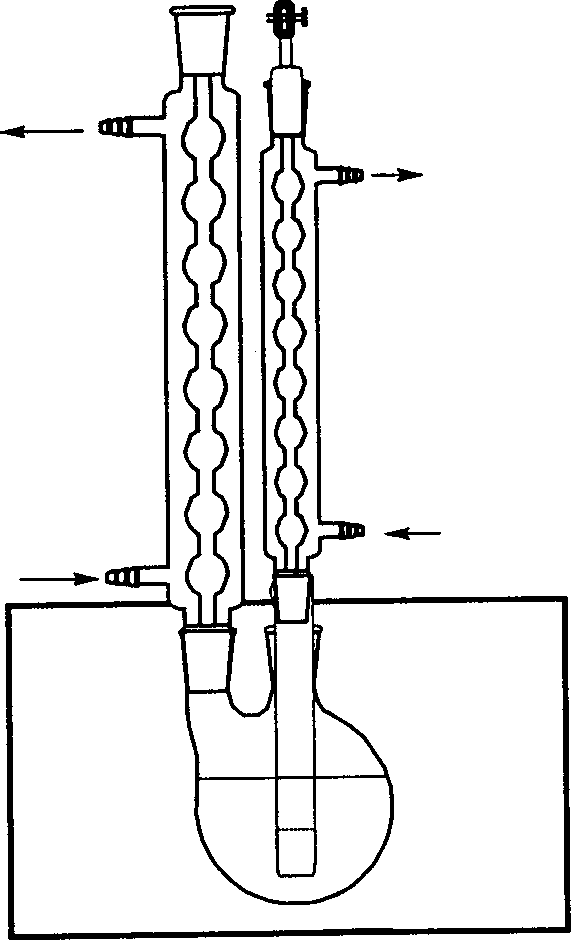

Preparation system and preparation method for polyisobutylene

The invention discloses a preparation system and a preparation method for polyisobutylene. The system comprises an isobutylene storage tank, a catalyst storage tank, a termination agent storage tank, a rapid mixer, a static mixing tube type polymerization reactor and a rapid reaction termination mixer. The isobutylene storage tank is connected to an isobutylene cooler through a pipeline and a raw material delivery pump. The isobutylene cooler is in pipeline connection with a raw material inlet of the rapid mixer. The catalyst storage tank is connected to the catalyst inlet of the rapid mixer through a pipeline and a catalyst metering pump. The outlet of the rapid mixer is communicated with the inlet of the static mixing tube type polymerization reactor, the outlet of which is communicated with the reaction feed inlet of the rapid reaction termination mixer. The termination agent storage tank is connected to the termination agent inlet of the rapid reaction termination mixer through a pipeline and a termination agent delivery pump. The static mixing tube type polymerization reactor is located in a constant temperature brine bath groove. The system provided by the invention has the advantages of uniform reaction temperature, narrow molecular weight distribution of polyisobutylene, and controllable molecular weight, etc.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Near-infrared light regulated methacrylate monomer polymerization method

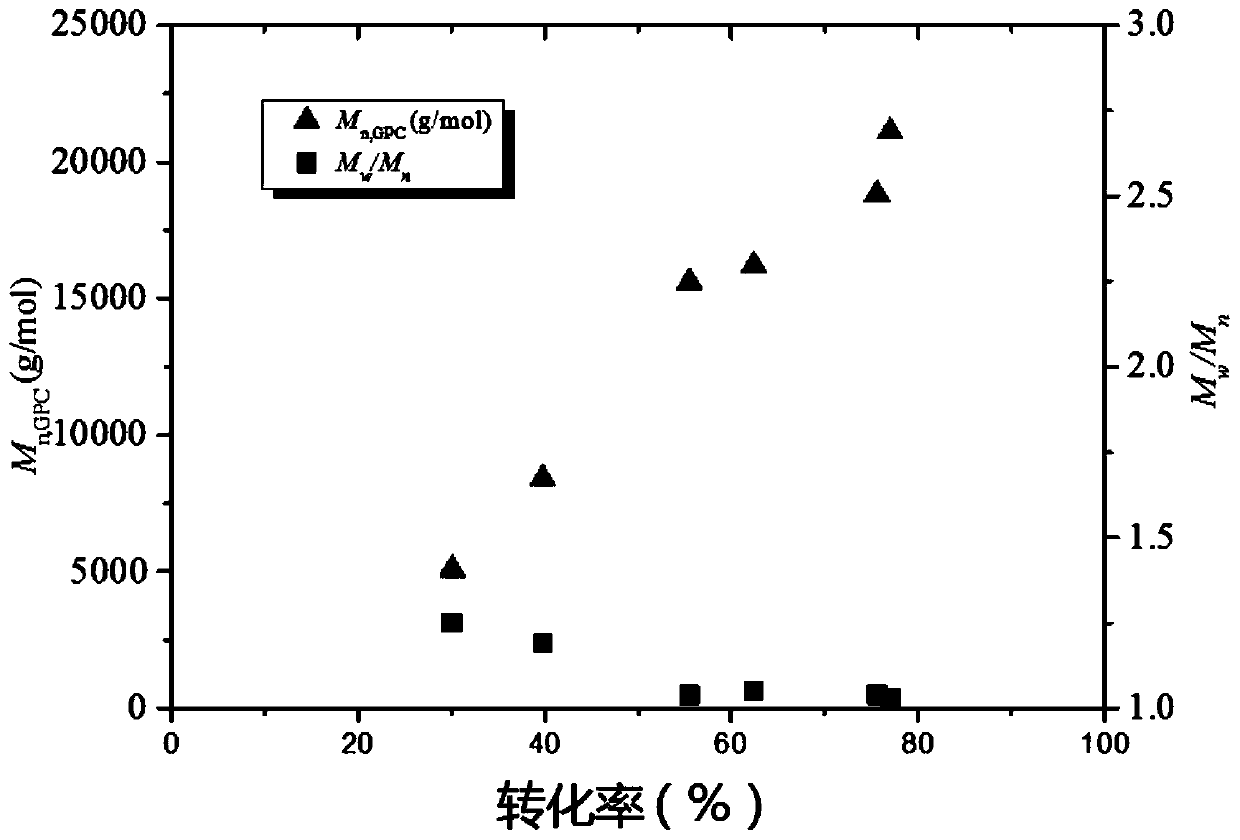

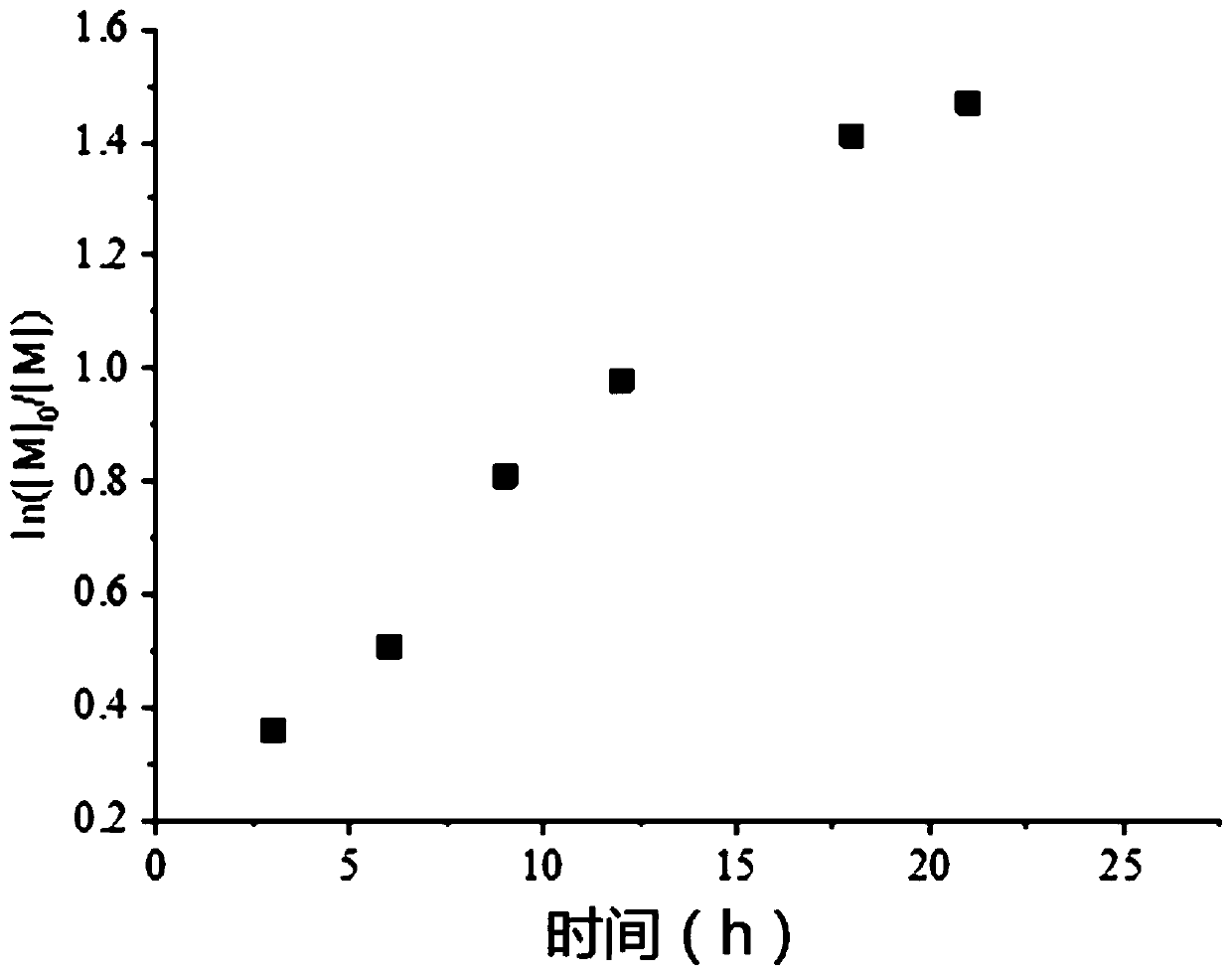

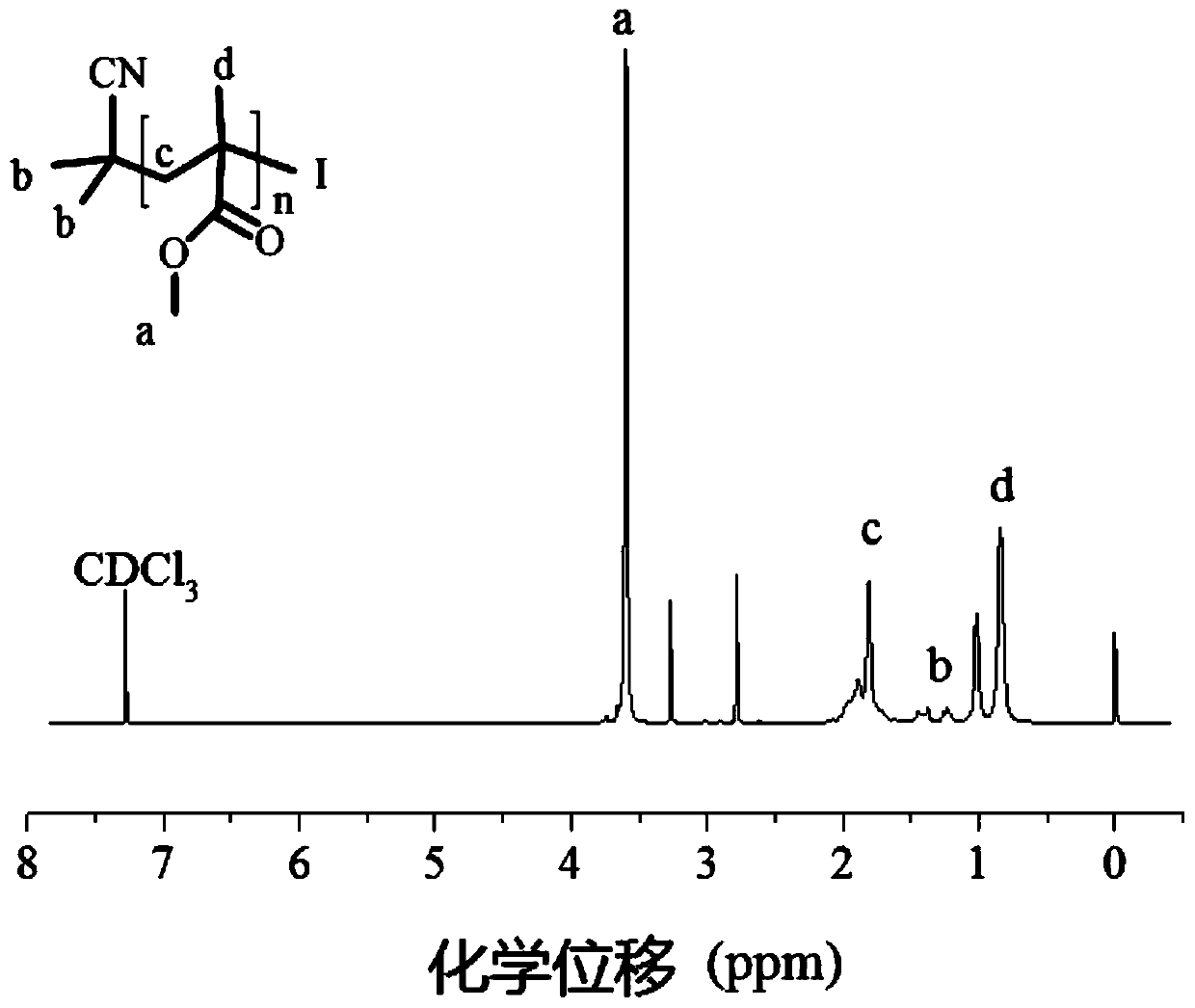

InactiveCN110128577ARealization of "Living" Radical Polymerization by Light Controlled Iodine TransferImprove conversion rateOrganic solventSolvent

The invention relates to a near-infrared light regulated methacrylate monomer polymerization method. The method comprises the following steps: dissolving a methacrylate monomer and an initiator in anorganic solvent, reacting the obtained solution at 20-30 DEG C under lights with a wavelength of 660-730 nm, and obtaining a polymethacrylate polymer after the completion of the reaction, wherein theinitiator is an iodo compound. The method of the invention has the advantages of simple polymerization component, mild reaction conditions, wide application range of the monomer, high designability ofthe molecular weight, and realization of the active free radical polymerization of the methacrylate monomer without a catalyst.

Owner:SUZHOU UNIV

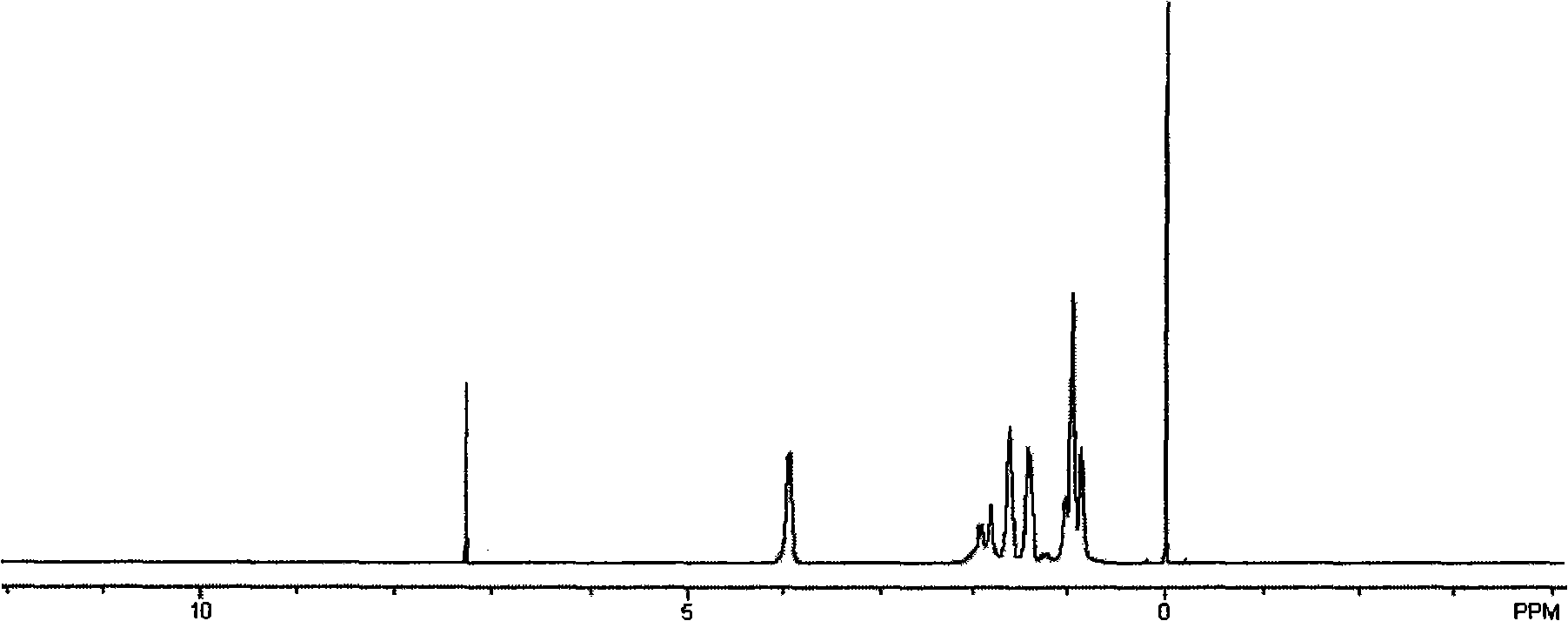

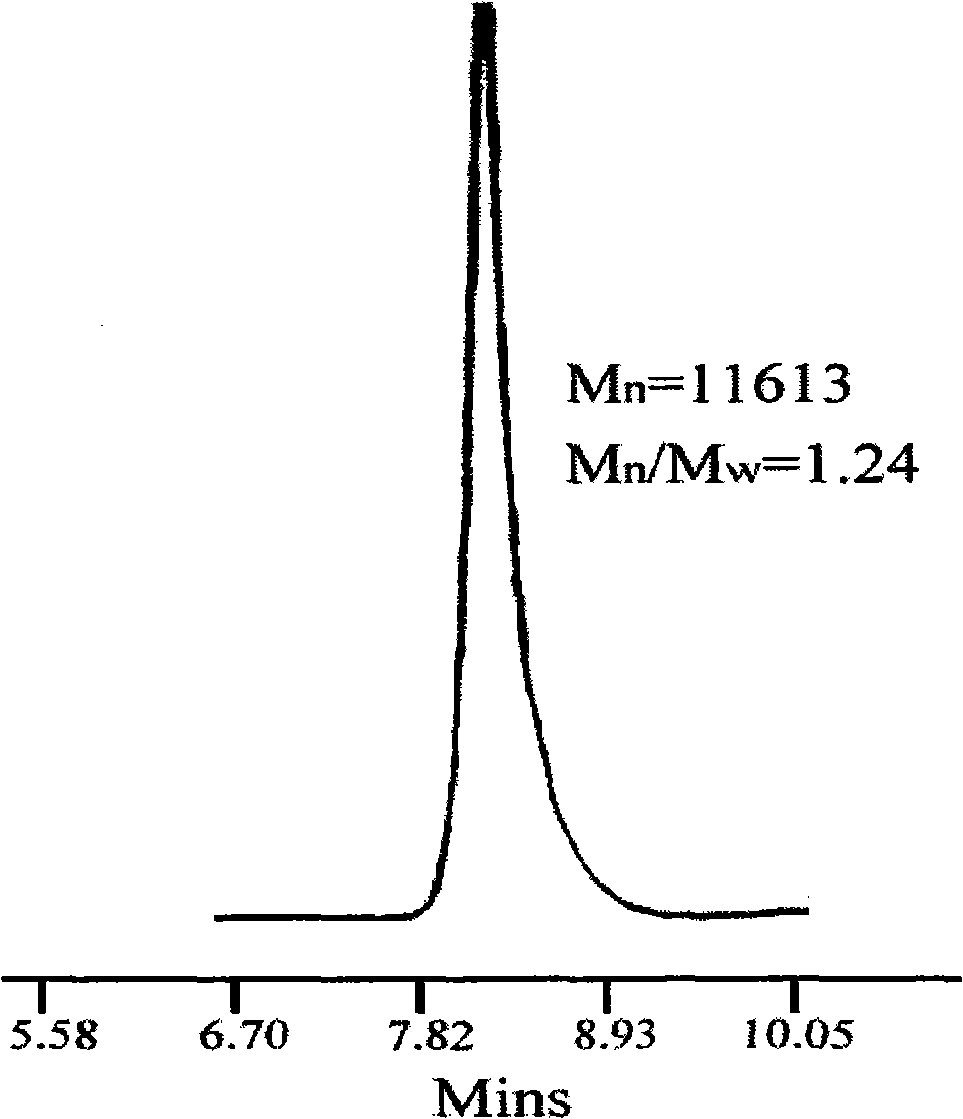

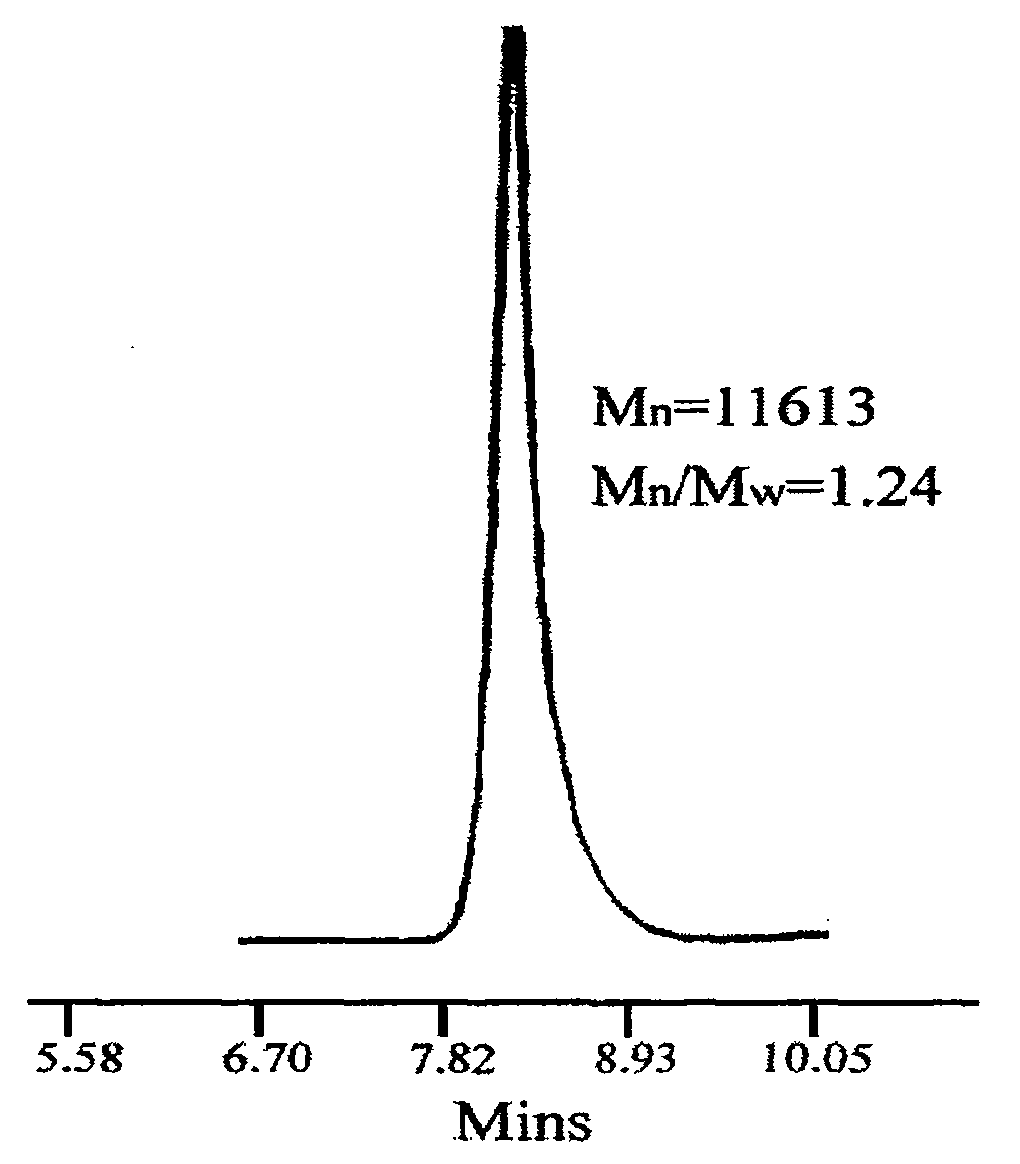

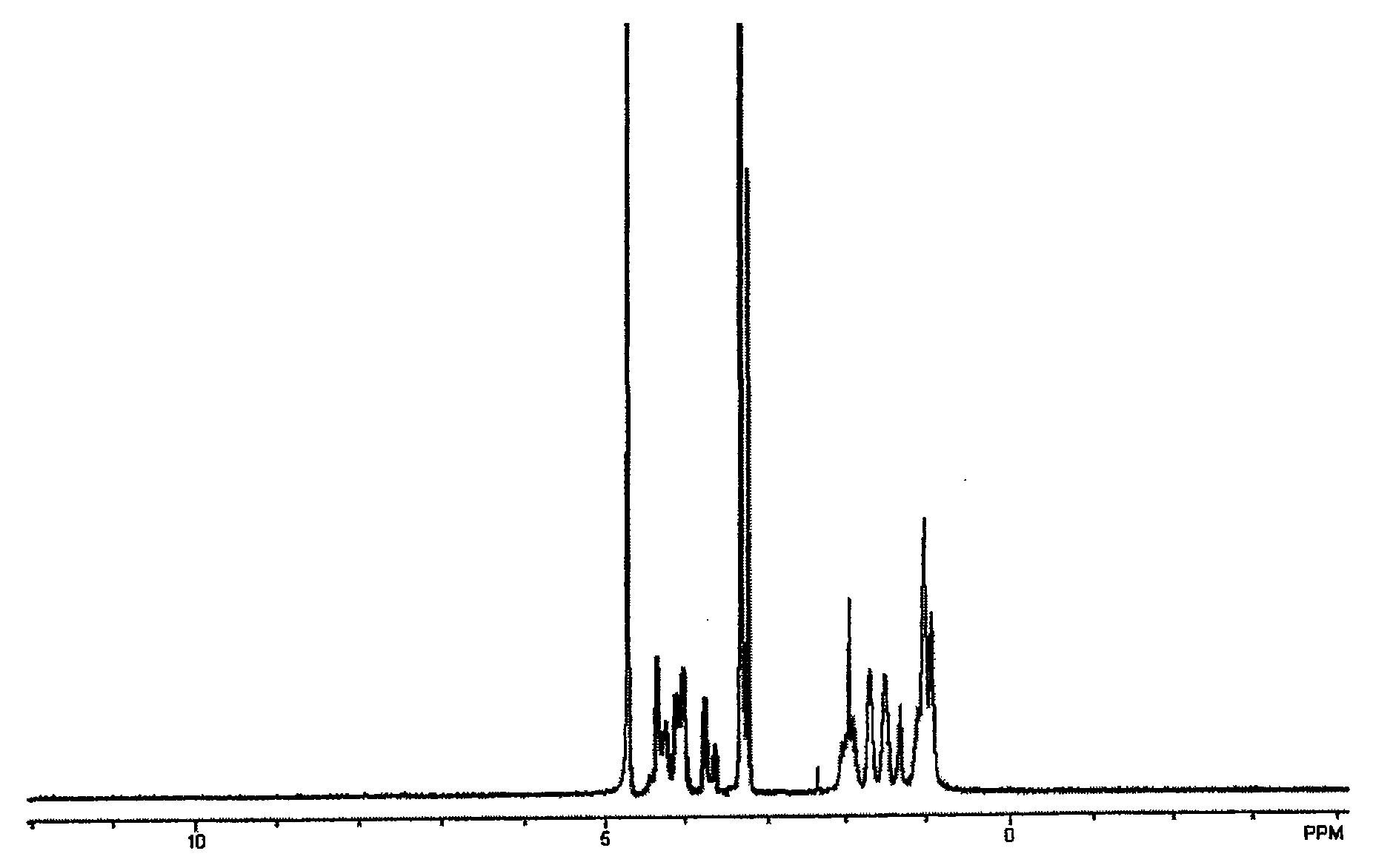

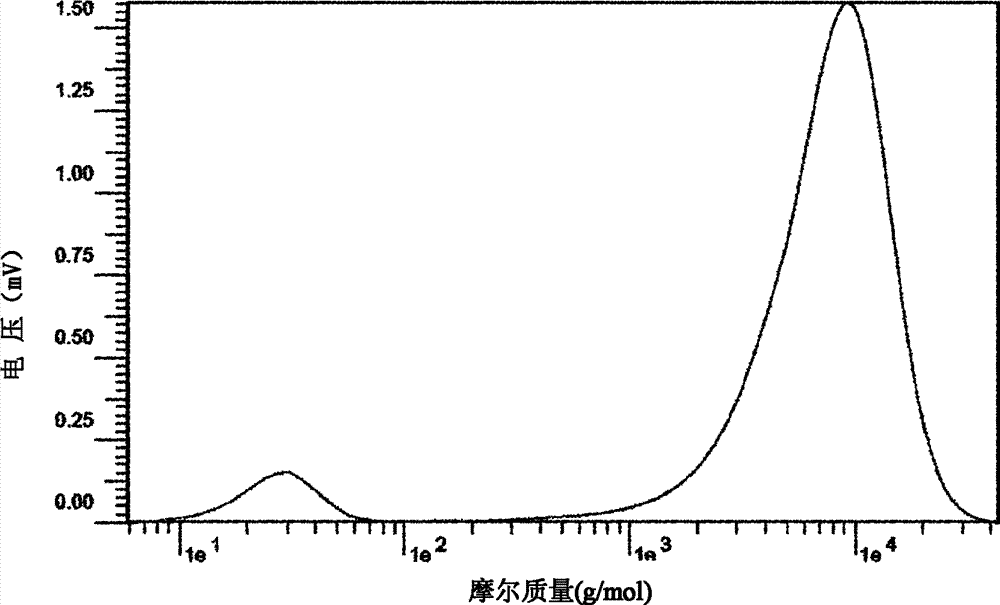

Bio-compatible monodisperse nano polymer carrier and its preparation and medicine-carrying method

InactiveCN100563716CMolecular weight distribution index is smallIncrease critical micelle concentrationOrganic active ingredientsPharmaceutical non-active ingredientsPhosphorylcholineBiocompatibility Testing

Biocompatible monodisperse nanopolymer carrier and methods for its preparation and drug loading. First, an amphiphilic block copolymer with a small molecular weight distribution index was prepared by reversible addition-fragmentation chain transfer (RAFT) polymerization, in which the hydrophilic segment was methacryloyloxyethylphosphorylcholine (MPC ), and the hydrophobic segment is n-butyl methacrylate (BMA). Then, the above-mentioned amphiphilic block copolymer is used to prepare nanometer polymer micelles by a solvent evaporation method, and drugs are encapsulated in the micelles by physical action to obtain a monodisperse nanometer polymer drug-carrying system with good biocompatibility.

Owner:SOUTHEAST UNIV

Imitated nylon modified fibre of dyeable polypropylene

InactiveCN101333691AImprove liquidityImprove flexibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureEthyleneDyeing

The invention relates to an imitated nylon differential fiber of dyeable polypropylene fiber for dyeing, which comprises: 80 to 90 percent of polypropylene, 9 to 11 percent of dyeable master batch, 0.3 to 0.7 percent of cooling auxiliary agent and 4.0 to 5.0 percent of polyethylene. The fiber has the advantages that: firstly, the polypropylene fiber has the flexibility, tensile property and elasticity as nylon through modifying the polypropylene fiber; and secondly, the dyeability of the modified polypropylene fiber is realized.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

Preparation method of acrylonitrile copolymer spinning solution with low molecular weight distribution

ActiveCN103030736AMolecular weight distribution index is smallQuality improvementMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention discloses a preparation method of an acrylonitrile copolymer spinning solution with low molecular weight distribution. According to the preparation method, in a solution polymerization process of an acrylonitrile monomer and a comonomer, the acrylonitrile monomer is supplemented once or multiple times within certain reaction time to adjust a weight-average molecular weight and a number-average molecular weight of a copolymer so as to reduce a molecular weight distribution index of the copolymer. Compared with other methods, the preparation method is simple and easy to implement in process; the molecular weight distribution index of the acrylonitrile copolymer prepared by using the method can be controlled between 2.5 and 3.0; and after residual monomers and bubbles of an acrylonitrile copolymer solution are removed, the acrylonitrile copolymer solution can be used as a spinning solution of high-performance polyacrylonitrile-based carbon fibers.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

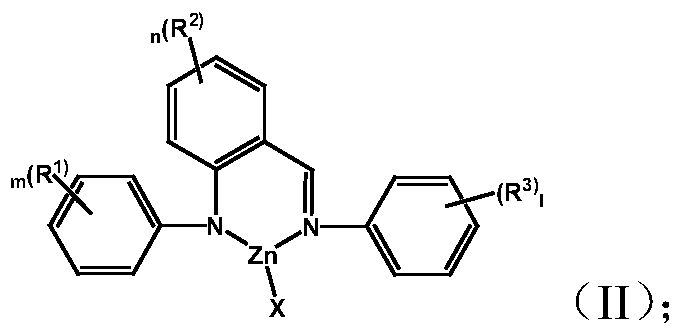

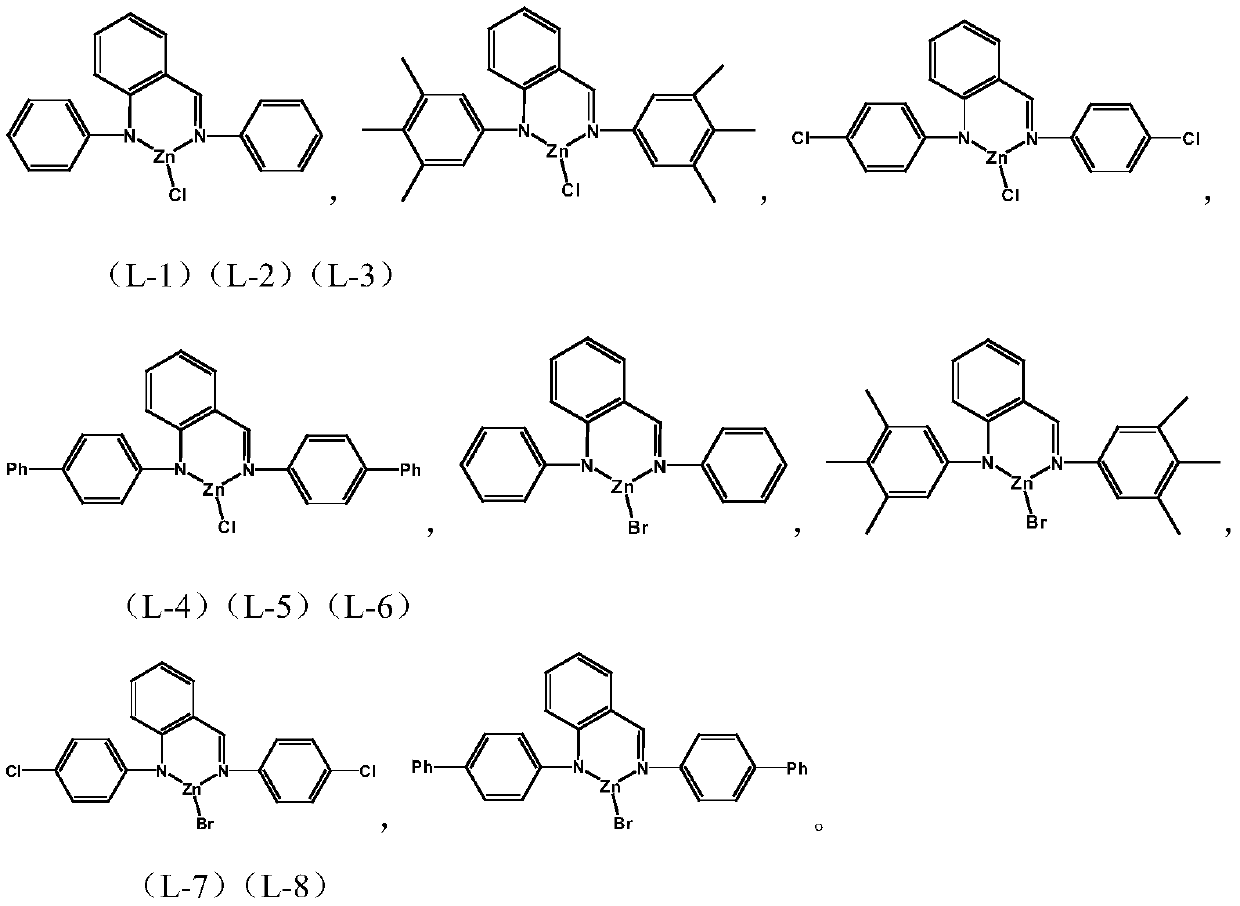

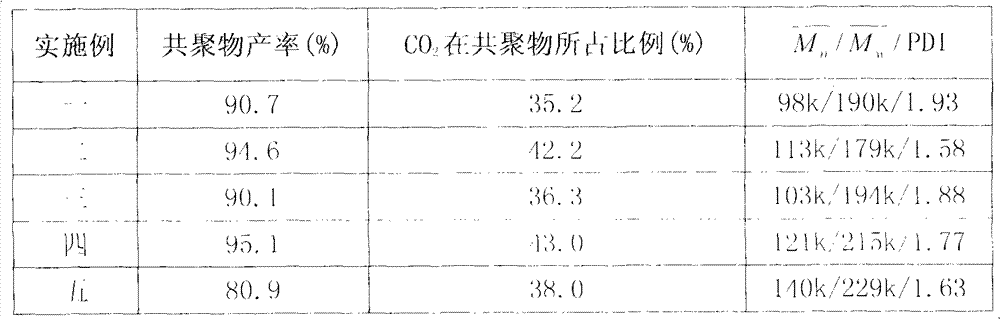

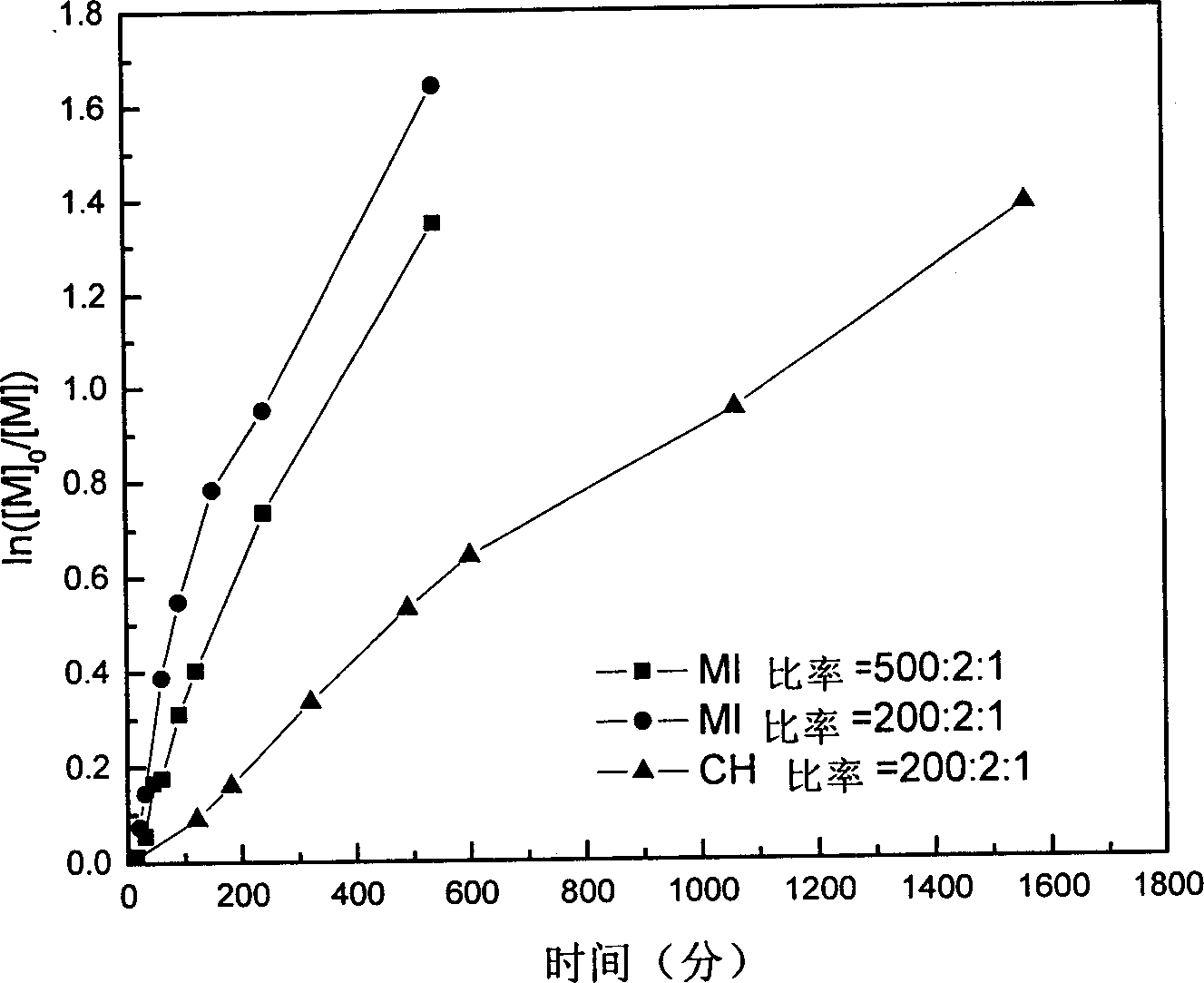

Double-metal cyanide catalyst for copolymerization of carbon dioxide and epoxide and preparation method of double-metal cyanide catalyst

The invention provides a double-metal cyanide catalyst for copolymerization of carbon dioxide and epoxide. The structural formula is M1a [M2 (CN) bLc] dXi, and the catalyst is obtained by mixing a complex M1LX of metal M1, cyanide of metal M2 and metal salt M1eXf and performing reaction under mechanical ball milling, wherein M1LX is a compound with a structure as shown in the following formula (II) which is described in the specification, M2 is selected from one of Co<2+>, Co<3+>, Fe<2+>, Fe<3+>, Cd<2+> and Mn<3+>, and X is selected from one or more of F<->, Cl<->, Br<->, I<->, NO3<->, SO4<2->or organic carboxylate anions. The preparation method of the catalyst is simple, convenient and green, the catalyst is high in catalytic efficiency, good in activity and good in stability, and in a carbon dioxide / epoxide copolymerization reaction, higher catalytic activity and higher selectivity of a polymer product and polycarbonate chain links on a polymer main chain can be embodied in a polymerization reaction under the conditions of relatively lower catalyst concentration and higher initiator concentration.

Owner:合肥普力先进材料科技有限公司

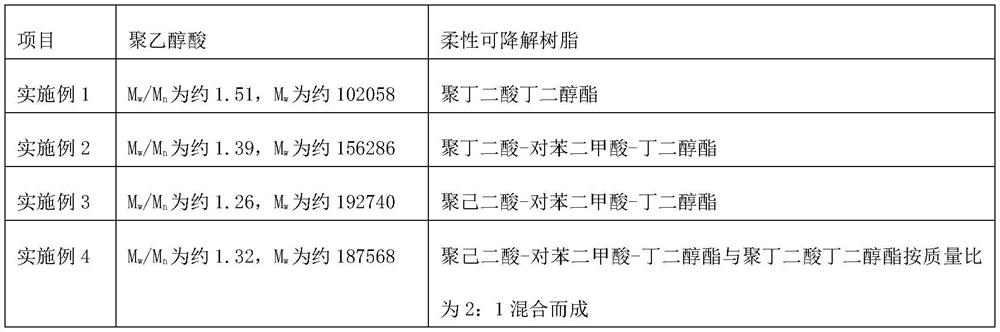

Degradable temporary plugging ball suitable for underground fracturing operation and preparation method thereof

ActiveCN113773823AEasy to crackPromote degradationDrilling compositionDomestic articlesPolymer sciencePlasticizer

The invention relates to a degradable temporary plugging ball suitable for underground fracturing operation. The degradable temporary plugging ball comprises the following raw material components in parts by weight: 70-90 parts of polyglycolic acid, 10-30 parts of a flexible degradable resin, 4-8 parts of a compatilizer, 2-5 parts of a plasticizer, 0.5-2 parts of a chain extender, 15-30 parts of a functional filler, 0.2-1.6 parts of an antioxidant, 2-4 parts of a heat stabilizer and 0.1-1 part of an anti-hydrolysis agent. Compared with the prior art, the polyglycolic acid and the flexible degradable resin are compounded, and the functional filler is supplemented, so that the material system has relatively high mechanical strength and certain flexibility, the heat-resistant stability of the material system can be effectively improved, and the prepared temporary plugging ball can still keep relatively stable plugging and pressure-bearing effects under a high-temperature condition, and has good degradability.

Owner:内蒙古浦景聚合材料科技有限公司

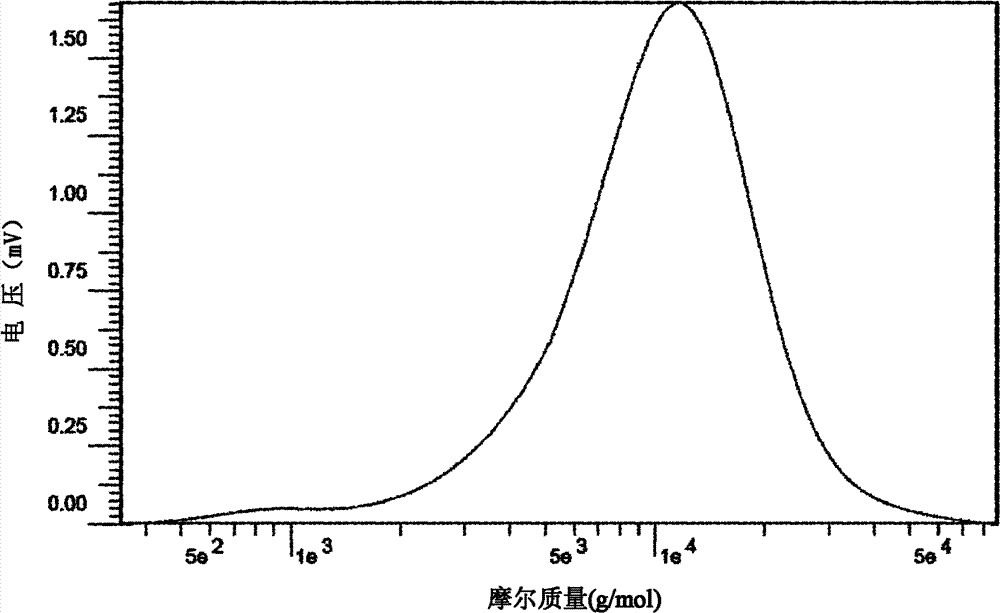

Method for preparing micromolecule pectin

ActiveCN102161712BMolecular weight distribution index is smallPharmaceutical non-active ingredientsDispersityPolymer science

Owner:SICHUAN YINGRUI PHARMA TECH CO

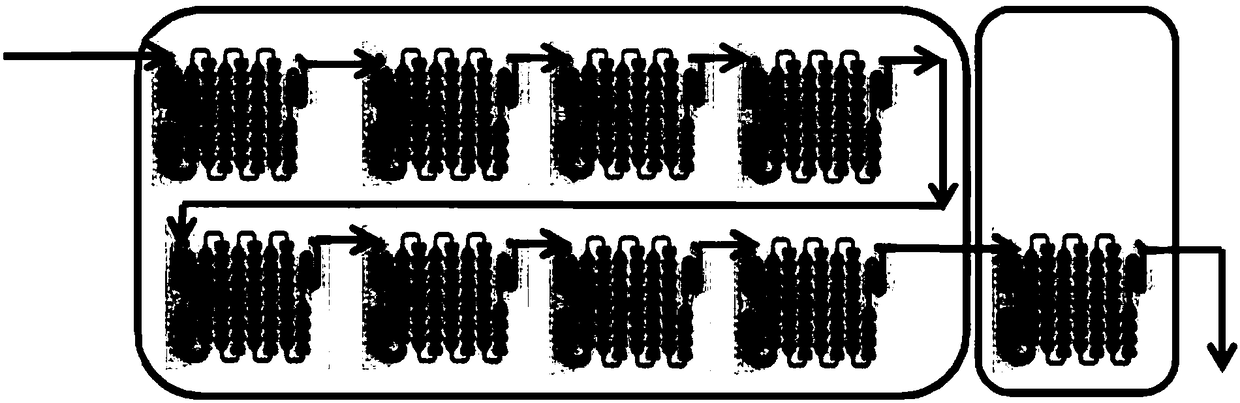

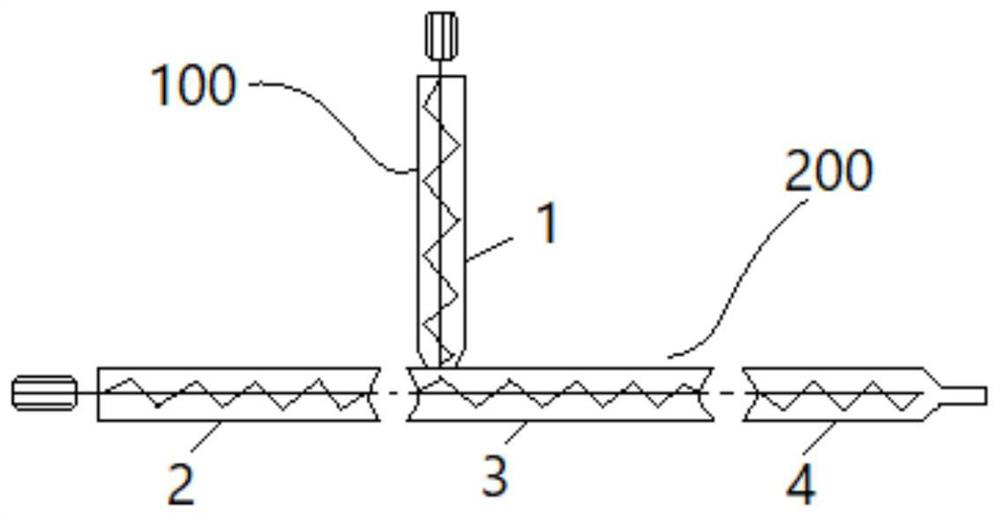

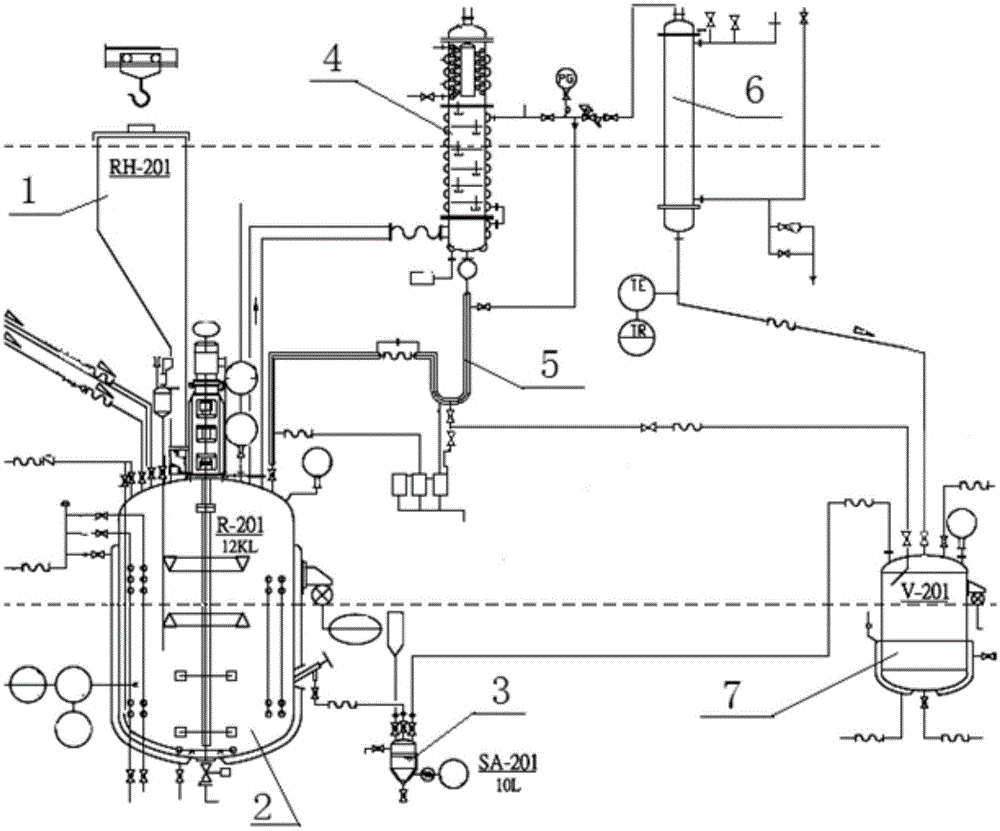

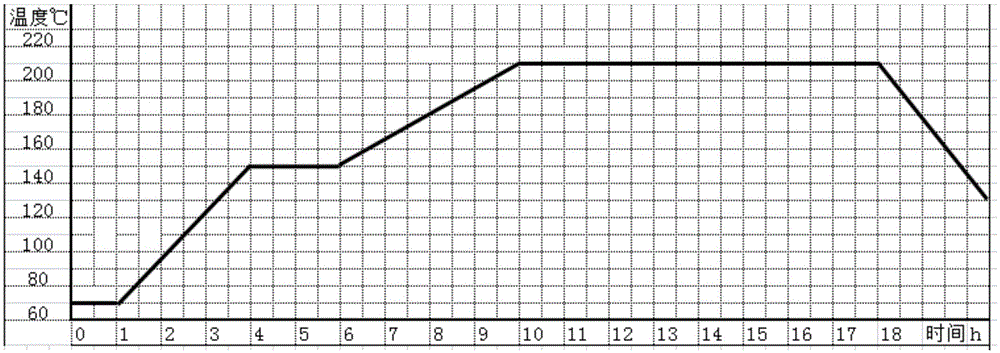

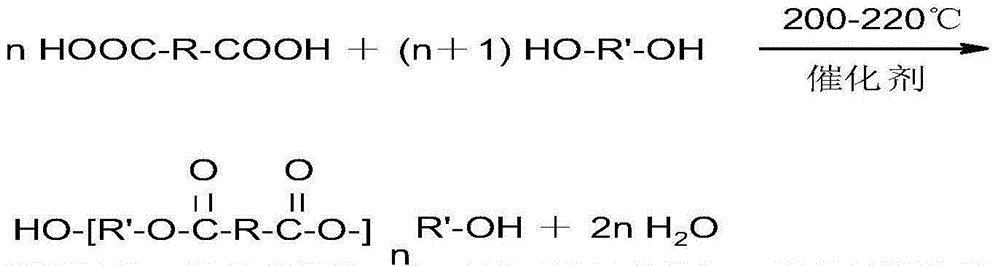

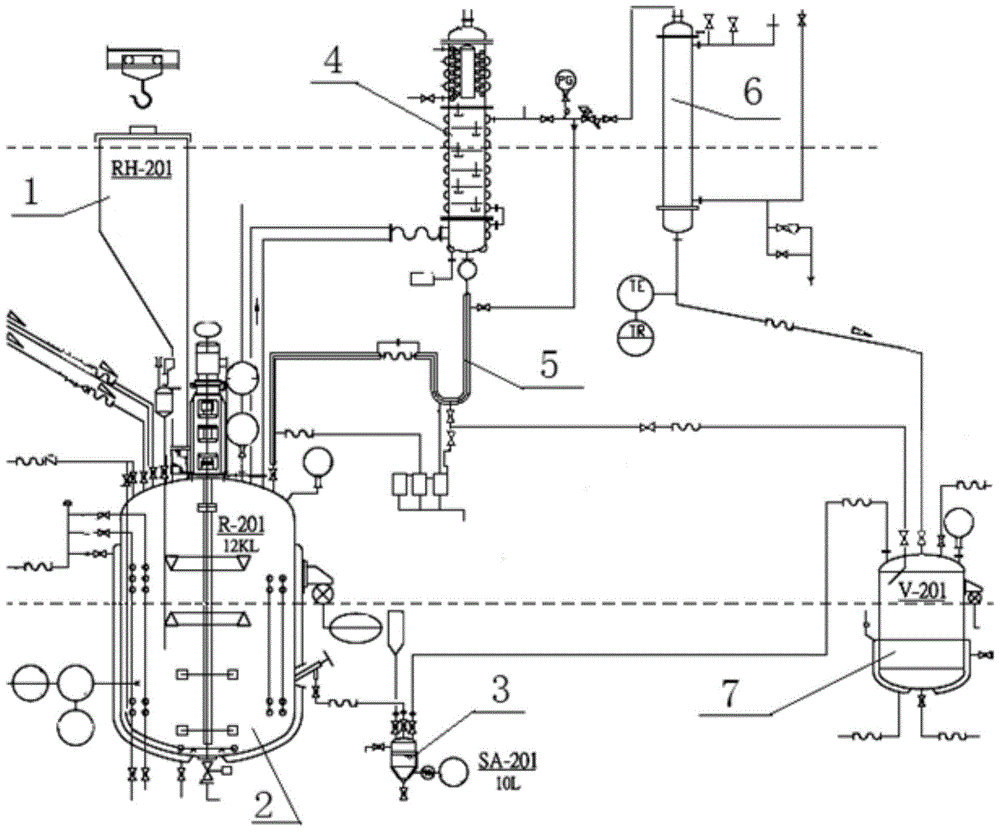

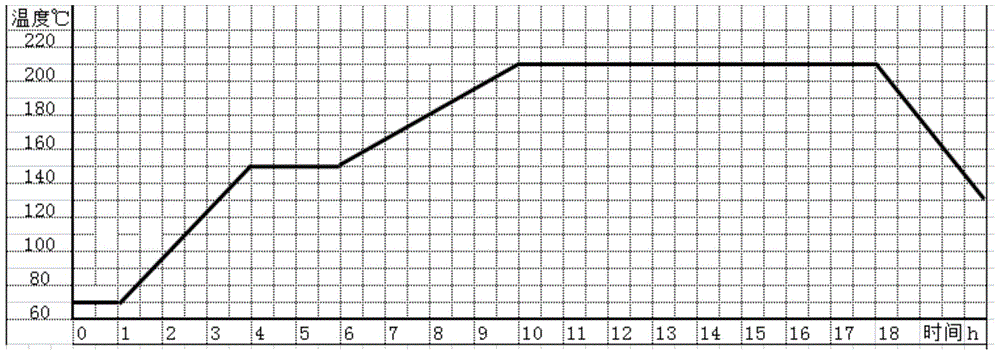

Fractionators narrowing polyester polyol molecular weight distribution

A fractionators narrowing polyester polyol molecular weight distribution is disclosed. A wastewater collection tank (7) is installed adjacent to a polyester reaction vessel (2), also a reflux pipe is connected between the upper end of the polyester reaction vessel (2) and the lower end of a dephlegmator (4), the reflux-pipe segment is provided with a U-shaped pipe (5), the communication bottom end of the U-shaped pipe (5) is connected with the wastewater collection tank (7), and the bottom of a condenser is connected with the wastewater collection tank (7); the dephlegmator (4) is connected with the condenser (6), the polyester reaction vessel (2) is connected with the dephlegmator (4), a return valve is arranged at the pipeline connecting the U-shaped pipe (5) with the polyester reaction vessel (2). The product quality is improved, alcohol removal labor hour is saved, the processing time of 6 KL of the raw material is shortened within 1 h from original 3-5 h, micromolecule alcohols are rapidly efficiently removed, polyester polyol molecular weight distribution is properly narrowed, and the molecular weight distribution index is relatively small. The cobalt-platinum colour is relatively low, and the acid value is relatively low and is within 0.1 mg KOH / g.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

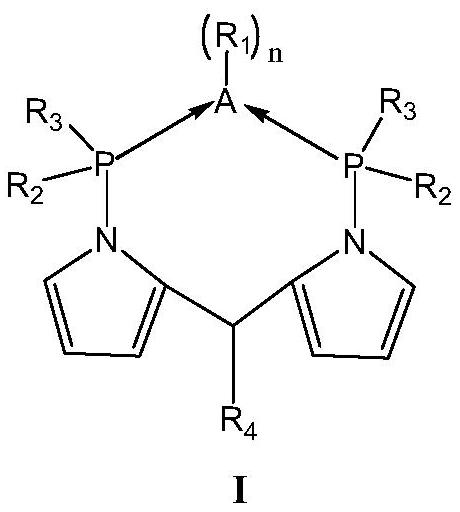

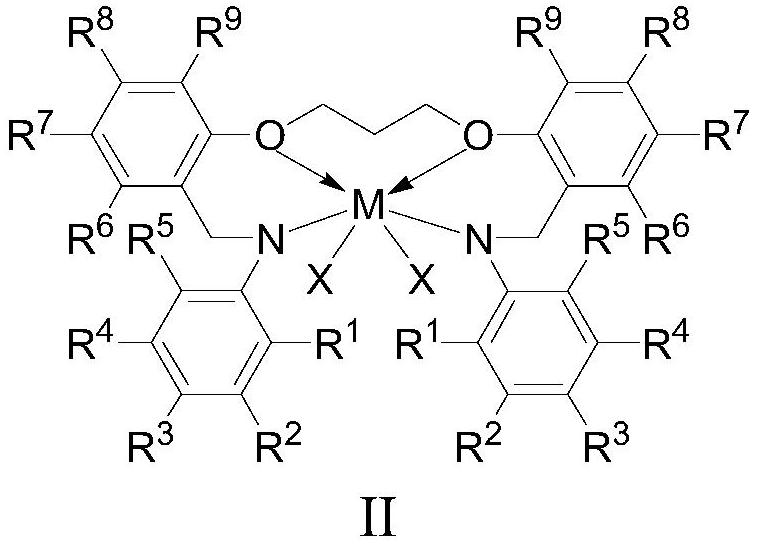

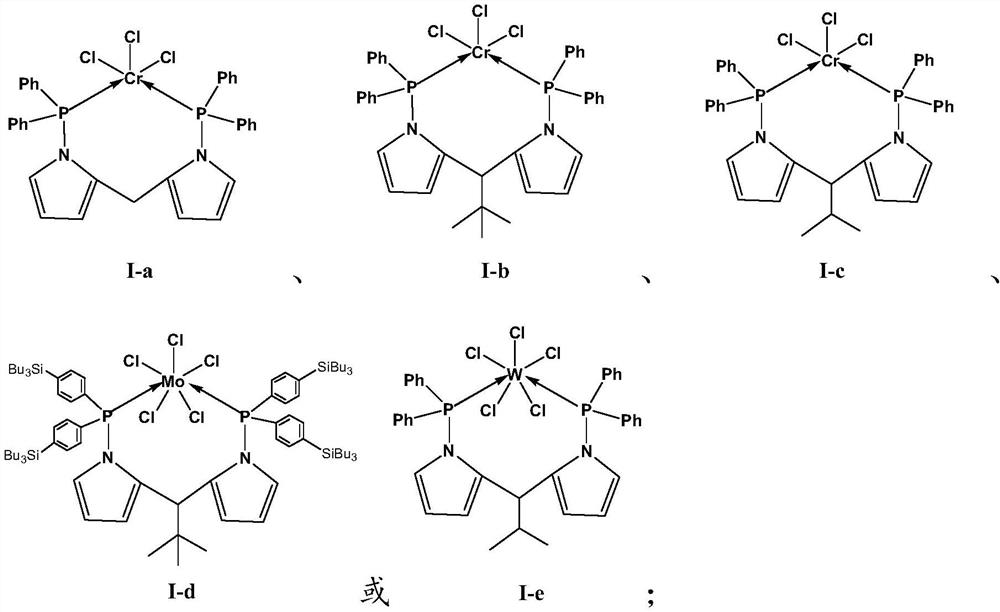

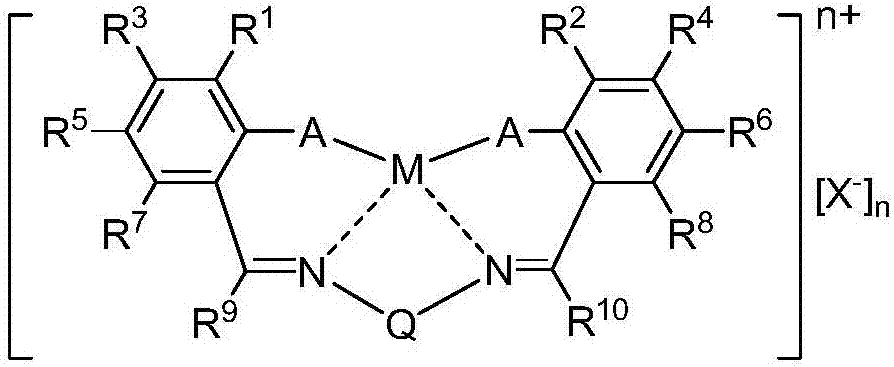

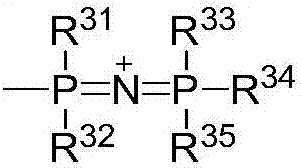

Cascade catalytic system and method for preparing LLDPE by using system

The invention relates to a catalyst composition for preparing LLDPE by cascade catalysis, a catalytic polymerization system for preparing LLDPE by cascade catalysis comprising the catalyst composition, a method for preparing LLDPE by using the polymerization system, and LLDPE prepared by the method. The catalyst combination comprises a first catalyst, a second catalyst and a cocatalyst, wherein the first catalyst is a pyrrolophosphine metal complex represented by a formula I, the second catalyst is an arylamino ether metal complex represented by a formula II, and the cocatalyst is selected from at least one of alkylaluminoxane, alkylaluminium or modified alkylaluminoxane. The LLDPE prepared by using the catalyst composition is relatively high in molecular weight, narrow in molecular weightdistribution and excellent in performance.

Owner:WANHUA CHEM GRP CO LTD

A kind of method adopting ultrafiltration and nanofiltration to prepare water-soluble chitosan oligosaccharide

ActiveCN103641936BImprove degradation efficiencyHeating fastSugar derivativesSugar derivatives preparationUltrafiltrationSeparation technology

The invention relates to a method for preparing water-soluble chitosan oligosaccharide by adopting ultrafiltration and nanofiltration. The method comprises the following steps: (1) preparing a chitosan oligosaccharide solution by using microwave hydrogen peroxide to perform compound degradation on chitosan; (2) separating out an active oligosaccharide concentrated solution by adopting an ultrafiltration and nanofiltration separation technology; (3) performing spray drying to obtain a chitosan oligosaccharide powder finished product. According to the method provided by the invention, the integrated production of reaction and separation of the finished product is realized, and the secondary degradation of active oligosaccharide is prevented. As the process realizes continuous operation, no other reaction byproducts are generated in the production process, and no pollutants are produced; compared with the preparation method in the prior art, the method has the advantages of advanced production process, simple generation process steps, low investment in production facilities, low cost, environmental friendliness, energy saving, and capability of rapidly realizing industrial production.

Owner:上海长欧生物科技有限公司

Method for synthesizing polylactic acid by adopting large-channel continuous flow microreactor

The invention belongs to the technical field of organic synthesis, and particularly discloses a method for synthesizing polylactic acid by adopting a large-channel continuous flow microreactor, and the method comprises the following steps of: dissolving lactide in an organic solvent, then injecting a lactide solution and a non-metal organic catalyst into the large-channel continuous flow microreactor, and carrying out polymerization reaction to synthesize the polylactic acid. According to the method, the non-metal organic catalyst is combined with the continuous flow microreactor, so that the continuous material ratio, the reaction temperature and the reaction time can be precisely controlled, the reaction realizes rapid mixing and mass transfer, and the obtained product is good in reproducibility, stable in quality, high in monomer conversion rate, high in polymerization degree and low in molecular weight distribution index, and can be controlled to meet the high requirement of 1.1-1.3, the yellow index is low, expanded production in industrial reaction is facilitated, and the problems of high synthesis reaction temperature, many side reactions, long residence time, low production efficiency and the like of polylactic acid in the prior art can be effectively solved.

Owner:上海东庚化工技术有限公司

A preparation method of biodegradable polymer material polyethylene lactide for medicine

ActiveCN110283305BAdjustable weight average molecular weightShort reaction timePtru catalystBulk polymerization

The invention provides a preparation method of medical biodegradable polymer material polylactate geycollic acid (PLGA). A mass polymerization method is adopted for manufacturing the polylactate geycollic acid (PLGA), the production technology is simple, conditions needed by the reaction are low, the reaction speed is high, and the reaction time is short; a catalytic system adopting an organic metal compound as a main catalyst and adopting a substance containing reactive hydrogen as an initiator is adopted as an efficient catalytic system, the reaction time is shorter compared with a single catalyst, the weight-average molecular weight of the product is adjustable, the lowest molecular weight distribution index can reach 1.40, the catalytic activity is high, and the PLGA is non-toxic basically; the reaction product is precipitated three times, unreacted monomers and low-molecular-weight by-products can be removed, the molecular weight distribution index is lowered, and the product purity is improved.

Owner:SHANDONG GUYUCHUN BIOTECHNOLOGY CO LTD

A kind of aluminum trichloride catalyst system and its method for producing low molecular weight polyisobutylene

ActiveCN105149005BSimple preparation processNo chemical reaction processOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOligomerOrganic matter

The invention discloses an aluminum trichloride catalyst system and a method for producing low-molecular-weight polyisobutene with the same and relates to a catalyst system and a method for producing polyisobutene with the same. The aluminum trichloride catalyst system is prepared from raw materials in parts by weight as follows: 5-50 parts of anhydrous aluminium trichloride powder and 50-95 parts of an isobutylene oligomer. The aluminum trichloride catalyst system is free of foreign organic matters and environmental pollution; the aluminum trichloride catalyst system has high adaptability to the raw materials and is used for polymerization production of the low-molecular-weight polyisobutene from an isobutylene-containing mixed C4 raw material, the required low-molecular-weight polyisobutene can be obtained, the low-molecular-weight polyisobutene product is high in purity and free of other organic matter residues, and an isobutylene oligomer byproduct can also be obtained.

Owner:SHANDONG HONGRUI NEW MATERIAL TECH

Fractionator for Narrowing the Molecular Weight Distribution of Polyester Polyols

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

A kind of polypropylene and its preparation method and application

ActiveCN107629155BHigh isotactic indexHigh melt flow indexMonocomponent polypropylene artificial filamentNon-woven fabricsPolymer sciencePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Imitated nylon modified fibre of dyeable polypropylene

InactiveCN101333691BImprove liquidityImprove flexibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureEthyleneDyeing

The invention relates to an imitated nylon differential fiber of dyeable polypropylene fiber for dyeing, which comprises: 80 to 90 percent of polypropylene, 9 to 11 percent of dyeable master batch, 0.3 to 0.7 percent of cooling auxiliary agent and 4.0 to 5.0 percent of polyethylene. The fiber has the advantages that: firstly, the polypropylene fiber has the flexibility, tensile property and elasticity as nylon through modifying the polypropylene fiber; and secondly, the dyeability of the modified polypropylene fiber is realized.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

Method for preparing double metal cyanide catalyst

The invention belongs to the field of chemical engineering, and particularly provides a method for preparing a double metal cyanide catalyst. The method comprises the following steps of: mixing water soluble metal salt and water soluble metal cyanide, and then carrying out mechanical ball milling to ensure that the water soluble metal salt and the water soluble metal cyanide undergo a mechanical chemical reaction; and removing the product, cleaning with a mixed solution, separating the precipitate, and drying the precipitate under a vacuum condition to obtain the double metal cyanide catalyst. The method is easy, can be used for synthesizing the double metal cyanide catalyst under a mechanical ball milling condition. The process is simple, consumes less time, has low usage of organic compounding ingredient and low cost, can greatly save raw materials and reduce energy consumption, and is suitable for industrial production and application.

Owner:HAINAN UNIVERSITY

Preparation method of acrylonitrile copolymer spinning solution with low molecular weight distribution

ActiveCN103014894BMolecular weight distribution index is smallQuality improvementMonocomponent synthetic polymer artificial filamentSpinning solutions preparationPolymer scienceAcrylonitrile

The invention discloses a preparation method of an acrylonitrile copolymer spinning solution with low molecular weight distribution. According to the invention, in a solution polymerization process between acrylonitrile monomers and comonomers, the weight-average molecular weight and number-average molecular weight of a copolymer are regulated in a continuous or intermittent cooling manner so as to reduce the molecular weight distribution index of the copolymer. Compared with other methods, the preparation method is simple and feasible and is stronger in process operability, the molecular weight distribution index of an acrylonitrile copolymer obtained according to the method can be controlled to be 2.3-2.8, and an acrylonitrile copolymer solution can be used as a high-performance polyacrylonitrile-based carbon fiber spinning solution after residual monomers and air bubbles are removed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of modified (meth)acrylate resin and preparation method thereof

The invention discloses modified (methyl) acrylate resin. The resin contains a (methyl) acrylate chain link, an unsaturated double bond and carboxylic group, an unsaturated double bond and epoxy group and an organic silicon group containing double bonds. The modified (methyl) acrylate resin can be solidified through various methods, has the characteristics of high hardness, high toughness, no adhesion, strong adhering force, good wear resistance and the like, and can be applied to fields such as coating, ink and adhesive. The invention further relates to a preparation method of the material.

Owner:CHINA LUCKY FILM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com