Degradable temporary plugging ball suitable for underground fracturing operation and preparation method thereof

A temporary plugging ball and fracturing technology, applied in the field of degradable temporary plugging balls and their preparation, can solve the problems of secondary pollution of underground reservoirs, difficulty in dissolving, and difficulty in forming pressure-bearing strength, and achieve lasting and stable sealing and pressure-bearing function, good mechanical strength and toughness, and the effect of improving pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

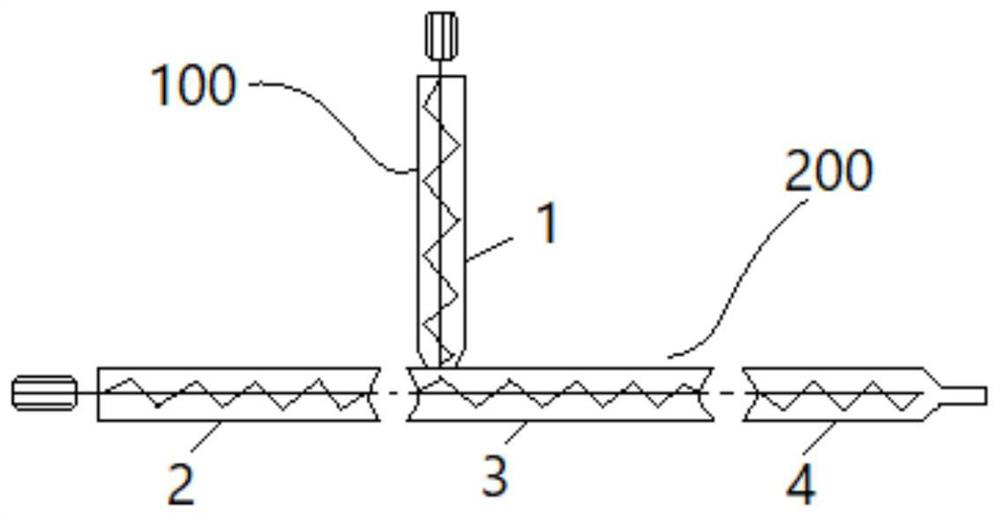

Image

Examples

Embodiment approach

[0070] As an embodiment, the antioxidant is selected from the group consisting of β-(3,5 di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 1,1,3 tris(2-methyl-4 Hydroxy-5-tert-butylphenyl)butane, 2,2'-methylenebis(4-ethyl-6-tert-butylphenol), 1,3,5-tris(3,5-tert-butyl-4- At least one of hydroxybenzyl)trimethylbenzene, 2,2'-methylenebis(4-methyl-6-tert-butylphenol) or 4,4'-di-tert-octyldiphenylamine.

[0071] As an embodiment, the heat stabilizer is an organic tin heat stabilizer, preferably dibutyltin maleate, dibutyltin dilaurate, dibutyltin laurate maleate, di-n-octyltin maleate, dilauric acid at least one of di-n-octyltin di-n-octyltin or bis(isooctylthioglycolate) di-n-octyltin.

[0072] As an embodiment, the anti-hydrolysis agent is bis(2,6-diisopropylphenyl)carbodiimide.

[0073] The preparation method of the degradable temporary blocking ball is as follows:

[0074] Step 1) Preparation of molten polyglycolic acid:

[0075] Step 1-1) Import the purified glycolide ...

Embodiment 1

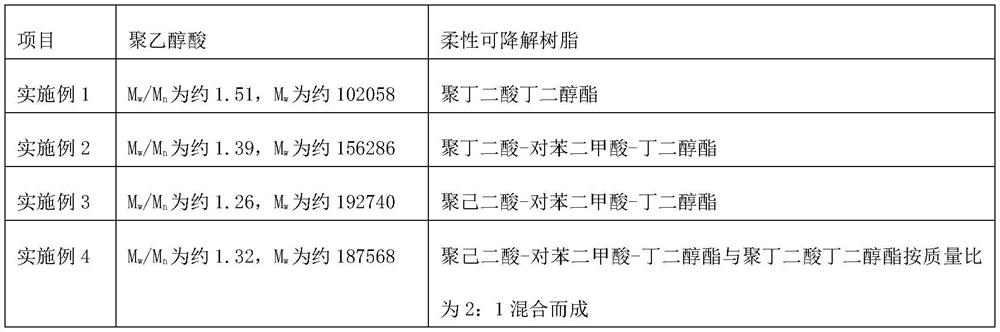

[0104] The formulation components are detailed in the table below.

[0105] The modified zeolite used is prepared by the following method:

[0106] Step i): Add zeolite powder to NaOH solution with a concentration of 10wt%, stir in a water bath at 50°C for 60 minutes, and then separate the solid from the liquid to keep the solid, wash it with deionized water until it is neutral, and place it at 80°C ℃ drying in an oven for 8 hours to obtain pretreated zeolite powder;

[0107] Step ii): adding the pretreated zeolite powder to an ethanol solution containing γ-aminopropyltrimethoxysilane and 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane (from anhydrous Mix ethanol and deionized water at a mass ratio of 1:5), stir in a water bath at 80°C for 2 hours to obtain a suspension, then transfer the suspension to an ultrasonic disperser, and use 400W ultrasonic at 35°C Treat for 2 hours, then centrifuge to retain the solid, wash with absolute ethanol several times, dry in an oven at 80...

Embodiment 2

[0110] The formulation components are detailed in the table below.

[0111] The modified zeolite used is prepared by the following method:

[0112] Step i): Add zeolite powder to NaOH solution with a concentration of 25wt%, stir in a water bath at 60°C for 20 minutes, centrifuge, keep the solid, wash with deionized water until neutral, and place at 80°C dried in a dry oven for 8 hours to obtain pretreated zeolite powder;

[0113] Step ii): adding the pretreated zeolite powder to an ethanol solution containing γ-aminopropyltrimethoxysilane and 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane (from anhydrous Mix ethanol and deionized water at a mass ratio of 1:1), stir in a water bath at 90°C for 1 hour to obtain a suspension, then transfer the suspension to an ultrasonic disperser, and use a 600W ultrasonic wave at 60°C Treat for 1 hour, then centrifuge to retain the solid, wash with absolute ethanol for several times, dry in an oven at 100°C for 10 hours, and grind until 95% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com