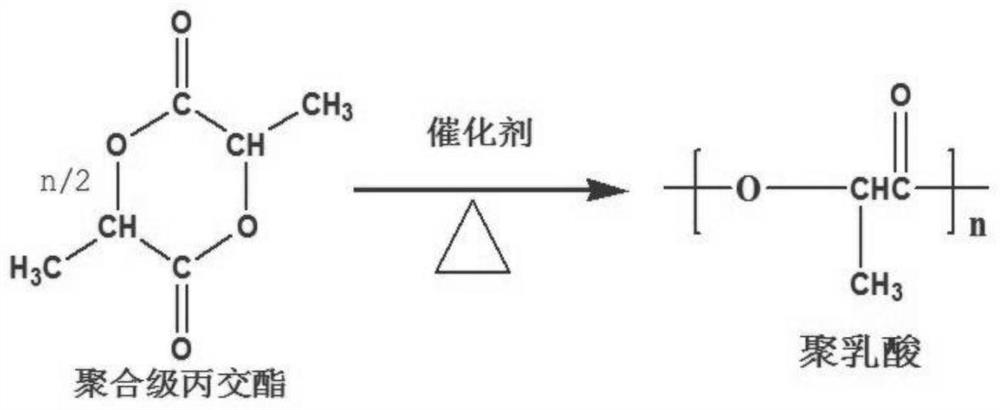

Method for synthesizing polylactic acid by adopting large-channel continuous flow microreactor

A micro-reactor and large-channel technology, applied in the field of organic synthesis, can solve the problems of many side reactions, large molecular weight distribution index, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

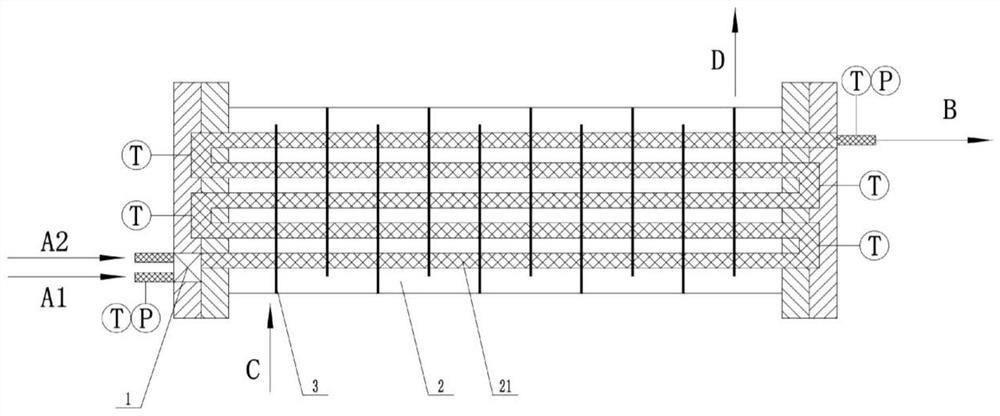

Method used

Image

Examples

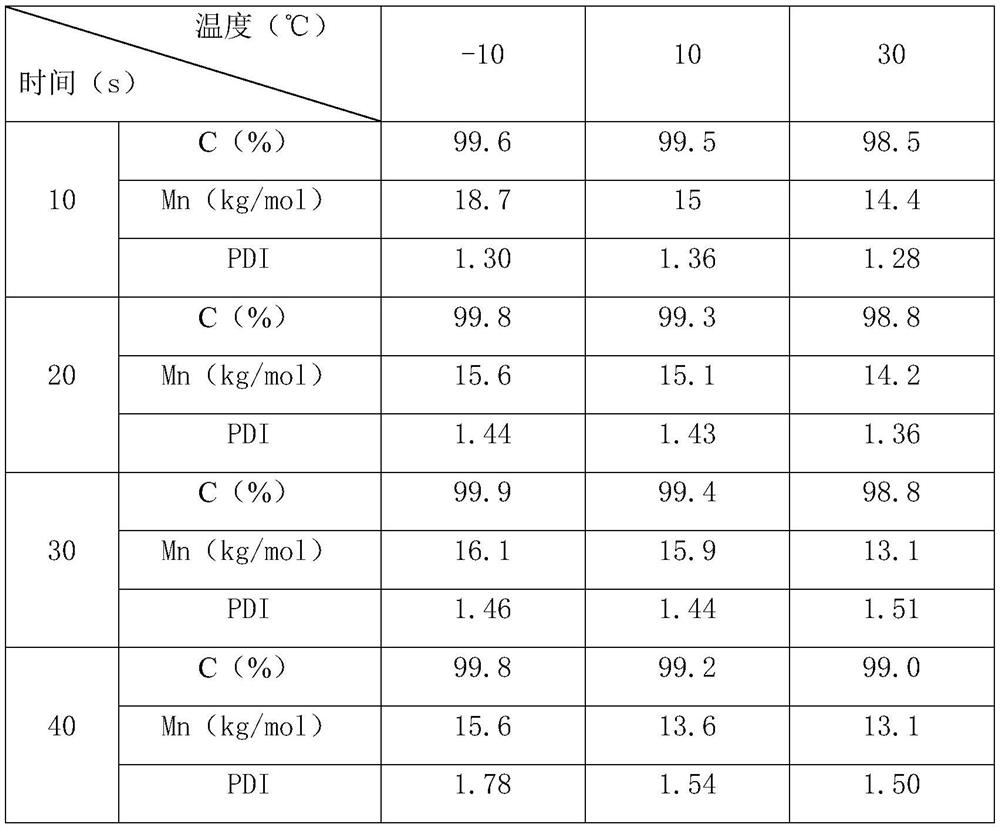

Embodiment 1

[0037] The loading capacity of catalyst is 1.2mol% of monomer, at reaction temperature-10 ℃, 10 ℃, 30 ℃, residence time 10s, 20s, 30s, 40s, measure its conversion rate C (%), number average molecular weight Mn ( kg / mol) and molecular weight distribution index PDI. The specific data are shown in Table 1:

[0038] Table 1

[0039]

Embodiment 2

[0041] The loading of the catalyst is 0.5mol% of the monomer, at the reaction temperature -10°C, 10°C, 30°C, the residence time is 10s, 20s, 30s, 40s, respectively measure the conversion rate C (%), the number average molecular weight Mn (kg / mol) and molecular weight distribution index PDI. The specific data are shown in Table 2:

[0042] Table 2

[0043]

Embodiment 3

[0045]The load of the catalyst is 0.25mol% of the monomer, at the reaction temperature -10°C, 10°C, 30°C, the residence time is 10s, 20s, 30s, 40s, respectively measure the conversion rate C (%), the number average molecular weight Mn (kg / mol) and molecular weight distribution index PDI. The specific data are shown in Table 3:

[0046] table 3

[0047]

[0048]

[0049] Can find out from embodiment 1-3:

[0050] 1. Under higher catalyst loading (monomer 0.5 mol% and above), the conversion rate of monomer is close to quantitative under all test conditions. When using 1.2mol% catalyst loading, the monomer conversion rate can reach ≥98.5% in the shortest 10s residence time. Residence times in excess of 10 seconds only lead to broadening of the molecular weight distribution.

[0051] 2. At a higher catalyst loading of 1.2mol%, PDI tends to increase, and the optimal reaction parameters can be quickly screened out by using a microreactor. In Example 1, a residence time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com