Fractionators narrowing polyester polyol molecular weight distribution

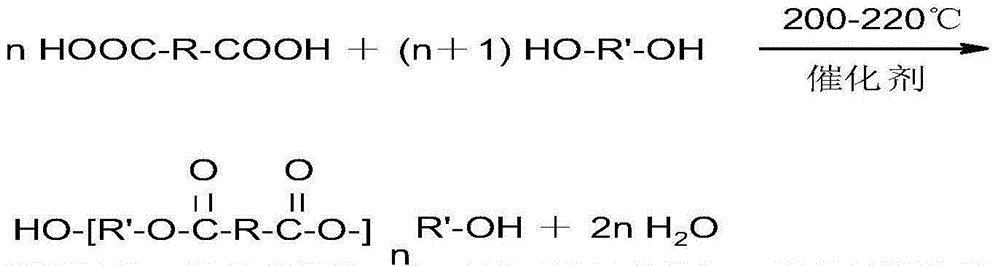

A polyester polyol and molecular weight distribution technology, which is applied in the field of fractionation tower devices, can solve the problems of deepening the chromaticity of polyester products, increasing the temperature of the fractionator, affecting the appearance and quality, etc., reducing the pipeline structure at the bottom and improving the product quality. The effect of quality and saving man-hours in dealcoholization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

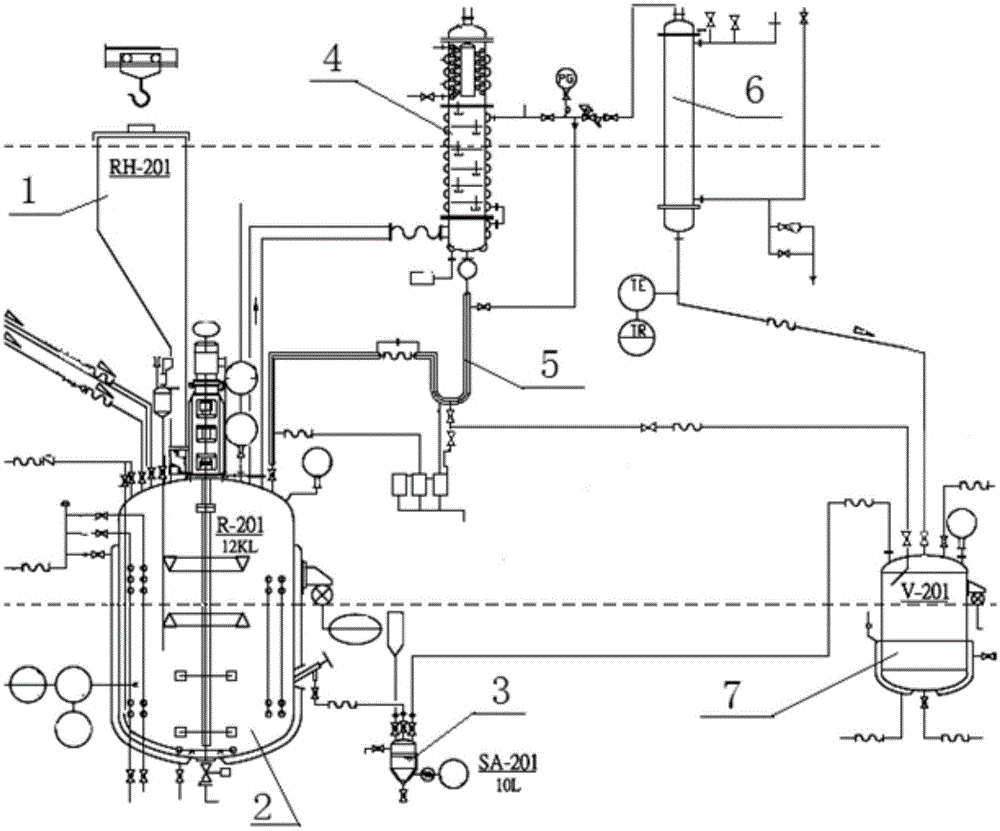

[0030] Embodiment 1: as attached figure 1 As shown, a powder funnel 1 is installed at the upper end of the polyester reactor 2, the upper end of the polyester reactor 2 is connected with a fractionator 4, the lower part of the polyester reactor 2 is installed and connected with a sampler 3, and a condenser 6 is installed next to the fractionator 4, Waste water collecting tank 7 is installed beside polyester reactor 2, and reflux pipe is connected between polyester reactor 2 upper end and fractionator 4 lower ends simultaneously, and U-shaped pipe 5 is connected on the reflux pipe section, and the connecting bottom on U-shaped pipe 5 The end is connected into the waste water collection tank 7, and the bottom of the condenser 6 is connected into the waste water collection tank 7.

[0031] In the foregoing, the polyester reactor 2 is connected to the fractionator 4 .

[0032] In the foregoing, the fractionator 4 is connected to the condenser 6 .

[0033] In the foregoing, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com