Method for preparing double metal cyanide catalyst

A double metal cyanide and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of multiple raw materials and the unbearable cost of catalyst preparation for industrial production, and achieve simple process, Save raw materials and energy consumption, the effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

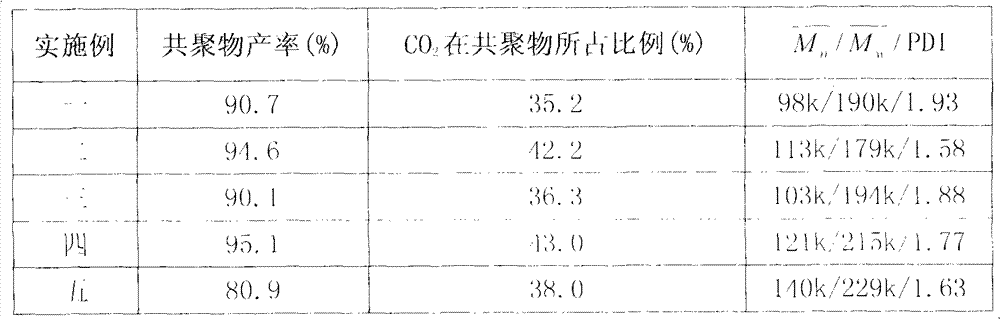

Embodiment 1

[0025] Zinc chloride (0.738g) and potassium hexacyanoferrate (III) (0.600g) were placed in the ball mill jar of the planetary ball mill, set to rotate at 600r / min, revolution at 120r / min, and run for 25 minutes. After the reaction was completed, the product was transferred to a Buchner funnel for filtration with a mixed solution of 15 mL of tert-butanol and water (1:1 by volume). Dry to constant weight in a vacuum oven at 55°C and grind to obtain a yellow powder, which is ready for use.

Embodiment 2

[0027] Zinc chloride (0.870g) and potassium hexacyanocobaltate (III) (0.626g) were operated according to the procedure in Example A to finally obtain a white powder for subsequent use.

Embodiment 3

[0029] In Example A, while adding the reactants, 300 μL of 1, 1, 1, 2, 2, 3, 4, 5, 5, 5 decafluoropentane was added, and ground for 18 minutes. Finally a yellow powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com