Amphoteric-polymer-based marine antifouling surface and preparation method thereof

An amphoteric polymer, marine antifouling technology, used in antifouling/underwater coatings, coatings, biocide-containing paints, etc., to achieve the effect of easy operation, prevention of marine biofouling, and good marine antifouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

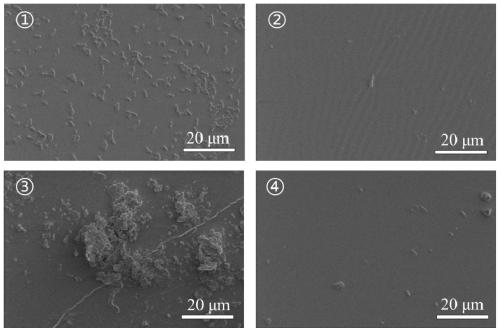

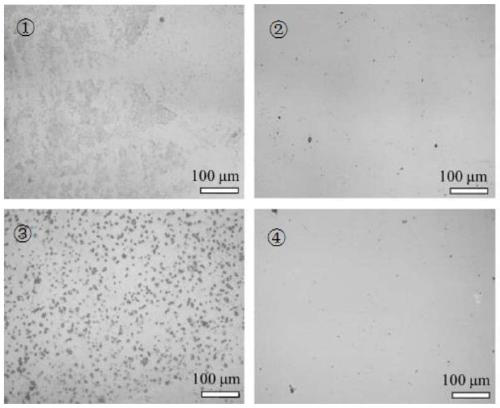

Image

Examples

Embodiment 1

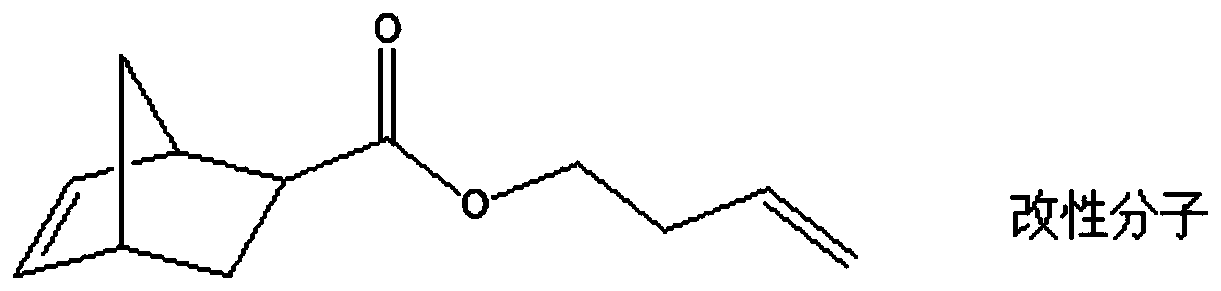

[0032] This embodiment provides a method for preparing an amphoteric polymer-based marine antifouling surface, comprising the following steps:

[0033] S1. Preparation of zwitterionic monomers:

[0034] Take 1.38g of norbornene acid and 1.34g of hydroxyethylimidazole into a 100ml round bottom flask, add 50ml of dichloromethane and stir to dissolve, then add 1.86g of N,N-dicyclohexylcarbodiimide and 0.06g of 4 - Dimethylaminopyridine. The temperature of the reaction was controlled at 0° C., and the reaction was completed after 24 hours. The precipitate was removed by filtration, and the obtained solution was washed with water, sodium bicarbonate and a saturated solution of sodium chloride in sequence, and after drying, the solvent was distilled off under reduced pressure. Then, 1.46 g of 1,3-propane sultone and 4 ml of acetonitrile were added to the product of the first step. After 48 hours of reaction at room temperature, ether was added to precipitate a white solid, which wa...

Embodiment 2

[0040] S1. Preparation of zwitterionic monomers:

[0041] Take 1.38g of norbornene acid and 1.23g of hydroxyethylimidazole into a 100ml round bottom flask, add 50ml of dichloromethane and stir to dissolve, then add 1.86g of N,N-dicyclohexylcarbodiimide and 0.06g of 4 - Dimethylaminopyridine. The temperature of the reaction was controlled at 20°C. After 18 hours, the reaction was completed, and the precipitate was removed by filtration. The resulting solution was washed with water, sodium bicarbonate and a saturated solution of sodium chloride in sequence, and after drying, the solvent was distilled off under reduced pressure. Then, 1.22 g of 1,3-propane sultone and 3 ml of acetonitrile were added to the product of the first step. After reacting at room temperature for 24 hours, ether was added to precipitate a white solid, which was dried at room temperature to obtain a zwitterionic monomer.

[0042] S2, preparation of modified polydimethylsiloxane (PDMS):

[0043] Take 10g ...

Embodiment 3

[0047] S1. Preparation of zwitterionic monomers:

[0048] Take 1.38g of norbornene acid and 1.34g of hydroxyethylimidazole into a 100ml round bottom flask, add 50ml of dichloromethane and stir to dissolve, then add 1.86g of N,N-dicyclohexylcarbodiimide and 0.06g of 4 - Dimethylaminopyridine. The temperature of the reaction was controlled at 10°C. After 36 hours, the reaction was completed, and the precipitate was removed by filtration. The resulting solution was washed with water, sodium bicarbonate and a saturated solution of sodium chloride in sequence, and after drying, the solvent was distilled off under reduced pressure. Then, 1.34 g of 1,3-propane sultone and 6 ml of acetonitrile were added to the product of the first step. After reacting at room temperature for 48 hours, diethyl ether was added to precipitate a white solid, which was dried at room temperature to obtain a zwitterionic monomer.

[0049] S2, preparation of modified polydimethylsiloxane (PDMS):

[0050] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com