Extreme-pressure lubricating and cutting liquid and preparation method thereof

A technology of extreme pressure lubrication and cutting fluid, applied in the field of extreme pressure lubrication cutting fluid and its preparation, to achieve the effect of improving lubricity, good dispersibility and enhancing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

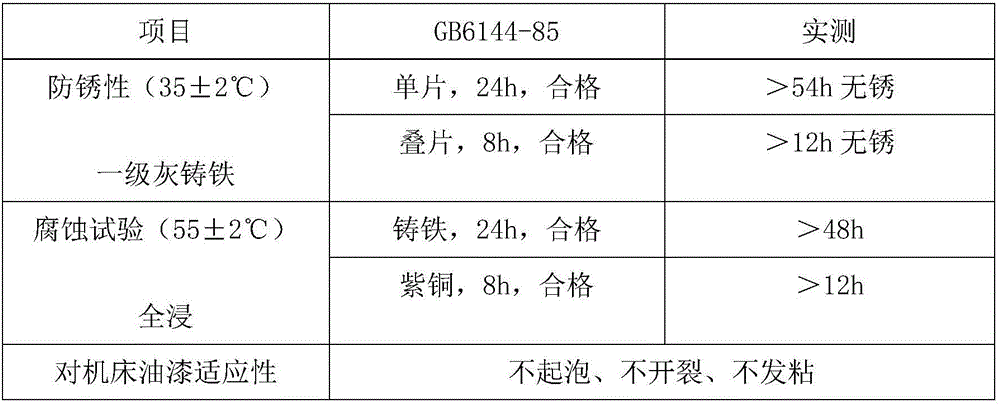

Image

Examples

Embodiment Construction

[0022] A kind of extreme pressure lubricating cutting fluid, it is made up of the raw material of following parts by weight:

[0023] N-Methylolacrylamide 1, Isopropyl Palmitate 3, p-Toluene Sulfonamide 1, T405 Sulfurized Olefin Cottonseed Oil 4, Copper Sulfate 0.2, Styrene 10, Maleic Anhydride 3, Benzoyl Peroxide 0.1, Nano Silica 5, propynyl alcohol 1, sodium nitride 0.4, aluminum chloride 0.6, silane coupling agent kh5600.7, sodium ascorbate 0.1, polyoxypropylene glyceryl ether 2, polyglycerol fatty acid ester 2, molybdenum oxide 0.1, calcium phosphate2.

[0024] A preparation method of the extreme pressure lubricating cutting fluid, comprising the following steps:

[0025] (1) Add the above-mentioned molybdenum oxide into dimethylformamide whose weight is 27 times, and ultrasonicate for 2 minutes to obtain the amide dispersion;

[0026] (2) Add the above-mentioned maleic anhydride to deionized water 20 times its weight, add polyoxypropylene glyceryl ether, raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com