Lithium ion battery

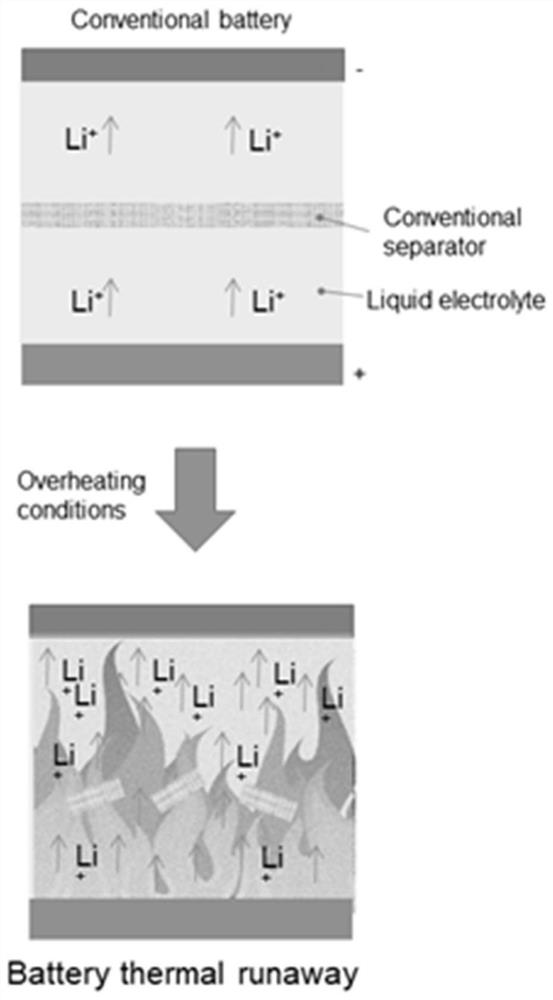

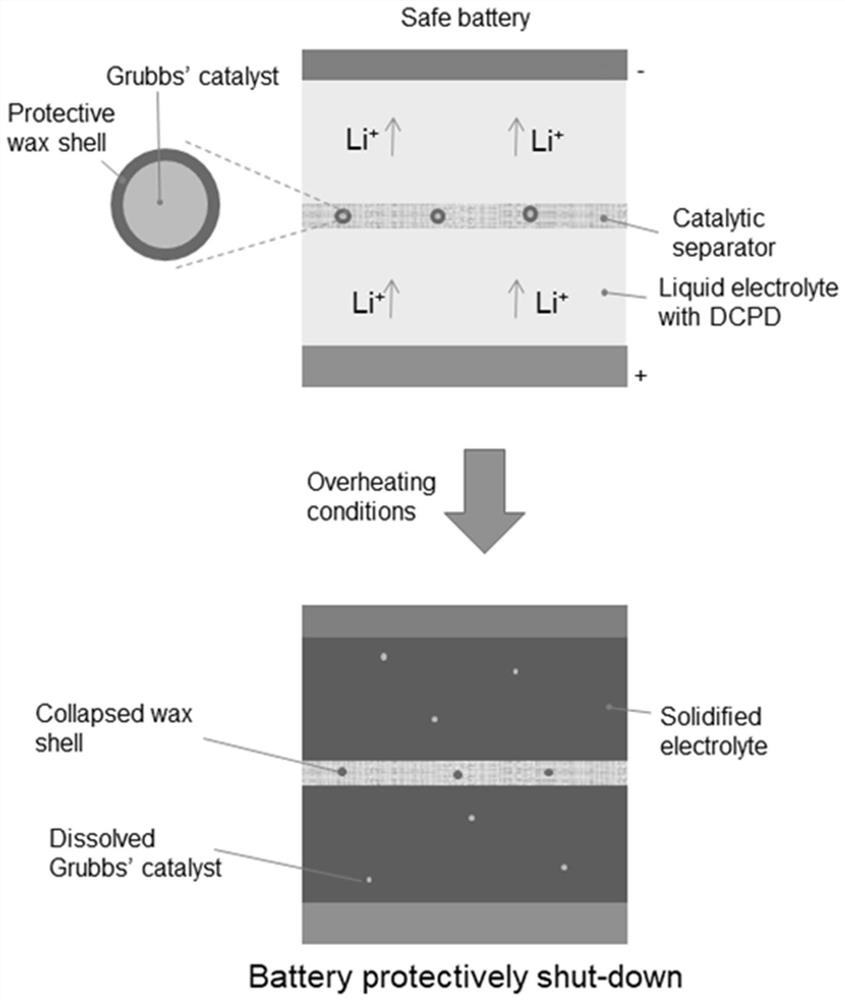

A lithium-ion battery and electrolyte technology, applied in secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as thermal runaway, reduced ionic conductivity, reduced battery energy density, etc., to prevent internal short circuits , the effect of ensuring safety and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

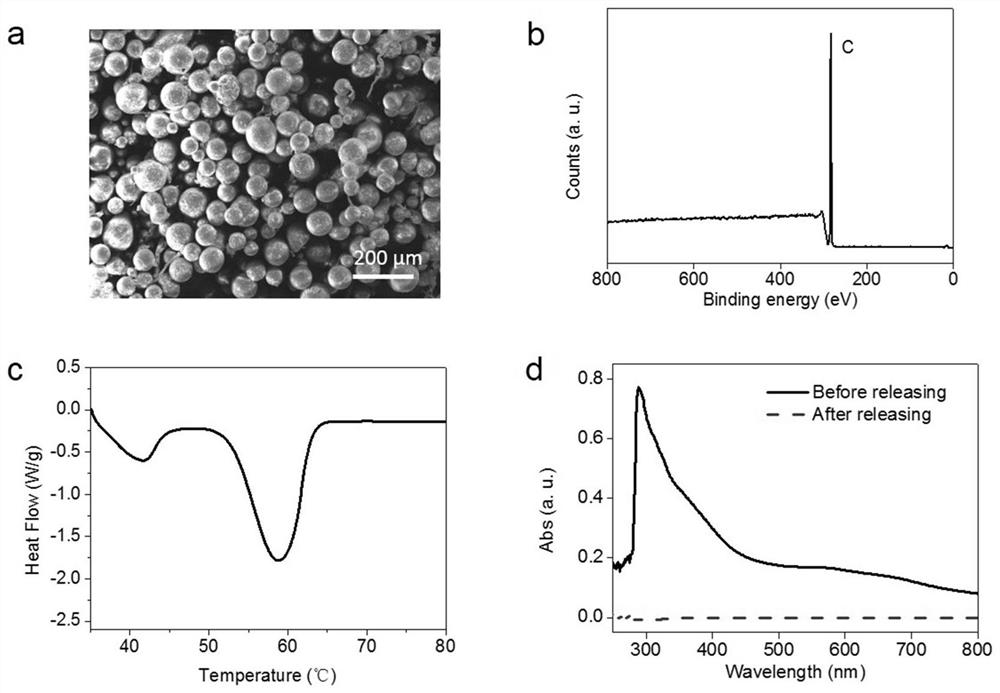

[0039] 1. Preparation of GC-loaded paraffin microspheres:

[0040] GC-loaded paraffin microspheres were prepared by melt-dispersion technique. Paraffin (2.0 g) and Grubbs catalyst (100 mg) were first sealed in the same vial, and then the vial was immersed in an 82°C water bath. In a separate vial, 17.5 ml of a surfactant / water mixture containing 0.5% polyvinyl alcohol (5 ml) and deionized water (12.5 ml) was prepared and preheated to 82°C. The mixture of paraffin wax and Grubbs catalyst (hot solution) was then added dropwise to the preheated surfactant / water mixture submerged in a water bath at 82 °C, and the mixture was emulsified with mechanical agitation at 2000 rpm for 2 minutes. Deionized ice water (0 °C, 50 ml) was quickly added to the above emulsion to solidify the paraffin microspheres loaded with Grubbs catalyst. The prepared microspheres are rinsed with deionized water to remove excess surfactant, and dried under vacuum to obtain the obtained microspheres.

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com