Organic molecular cage loaded catalyst, synthesis method and application thereof

A technology for supporting catalysts and organic molecules, applied in the field of organic molecular cage-supported catalysts and their synthesis, can solve the problems of insignificant variability of monomer units, polydispersity of molecular weight, expensive raw materials, etc., and achieves wide industrial application prospects, separation Simple, easy-to-use ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

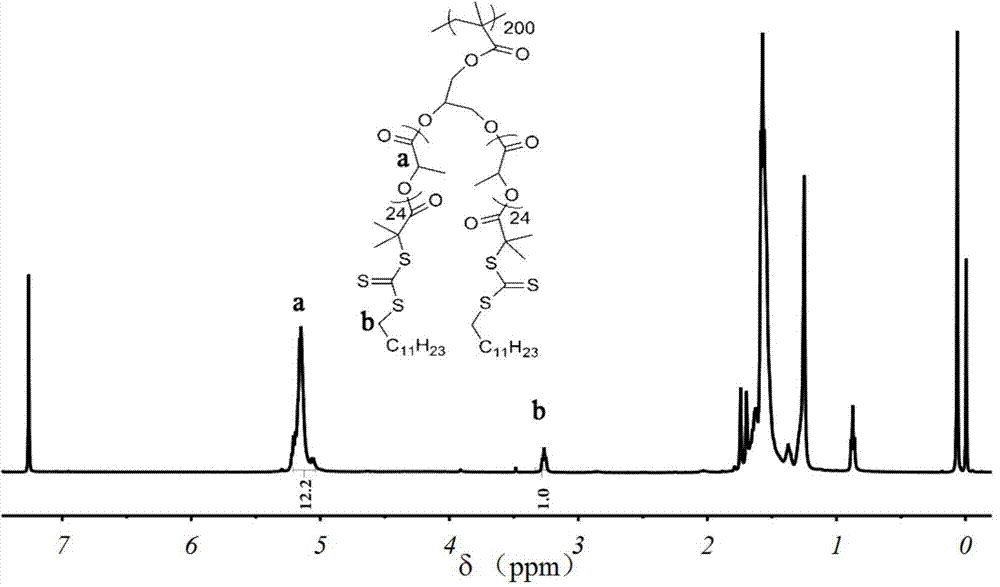

[0049] The synthetic method of organic molecular cage supported catalyst of the present invention comprises the following steps:

[0050] (1) Using glycidyl methacrylate (GM) as a monomer, synthesize the main chain of PGM through RAFT polymerization, and hydrolyze the epoxy groups on the main chain to form hydroxyl groups; DL-lactide ring-opening is triggered under the catalysis of DBU Polymerize to generate a PLA (polylactic acid) degradation layer; then install a RAFT chain transfer agent at the hydroxyl end. Then random copolymerization of 4-vinyl benzyl chloride (VBC) and 4-butenyl styrene (BS) is grafted onto the molecular main chain; in order to increase its solubility and increase steric hindrance, another layer is connected outside N-isopropylacrylamide (NIPAAm); obtain organic molecule cage supported catalyst precursor; as Figure 11 shown.

[0051] (2) The above-mentioned obtained organic molecular cage precursor is cross-linked with the first-generation Grubbs cat...

Embodiment

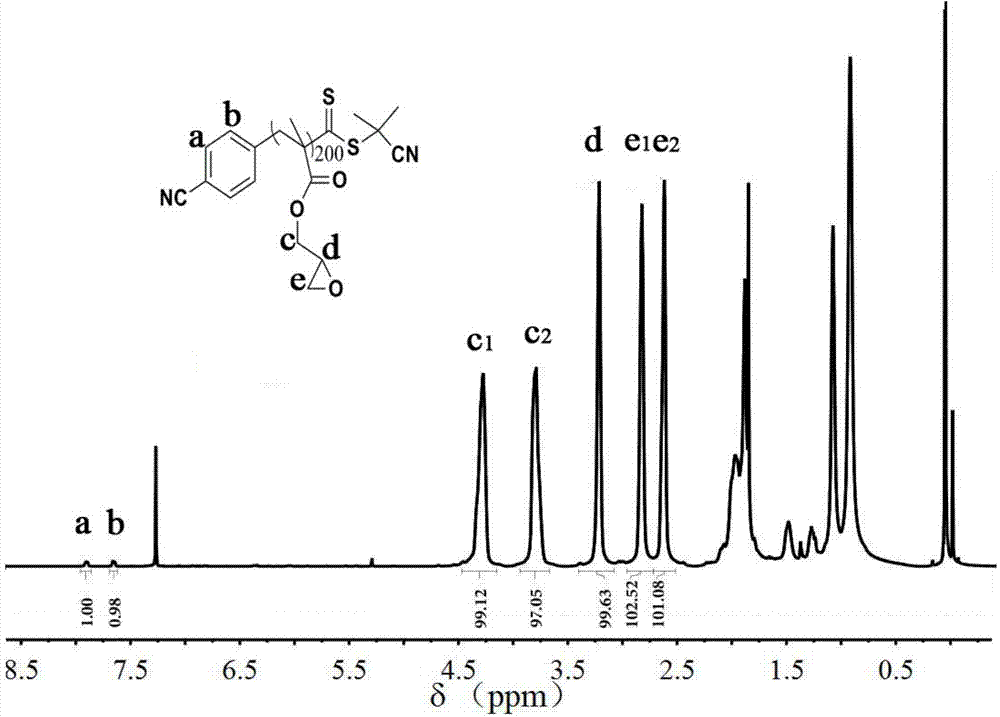

[0078] (1) Synthesis of organic molecular cage precursors

[0079] Add 20mgP(GM-g-LA-VBC\BS), 255mgNIPAAm, 0.03mgAIBN, 0.8ml1,4-dioxane to the reaction test tube, and react at 60°C for 4h after deoxygenation for 3 times by freezing-pump-thawing . After the reaction, the reaction solution was precipitated in ether, and after centrifugation, the solvent was removed, dissolved in THF, and precipitated in ether, and repeated twice. Weigh 50 mg (11.7%) after drying. PDI = 1.20. 1 HNMR in CDCl 3 n(NIPAAm)=300.

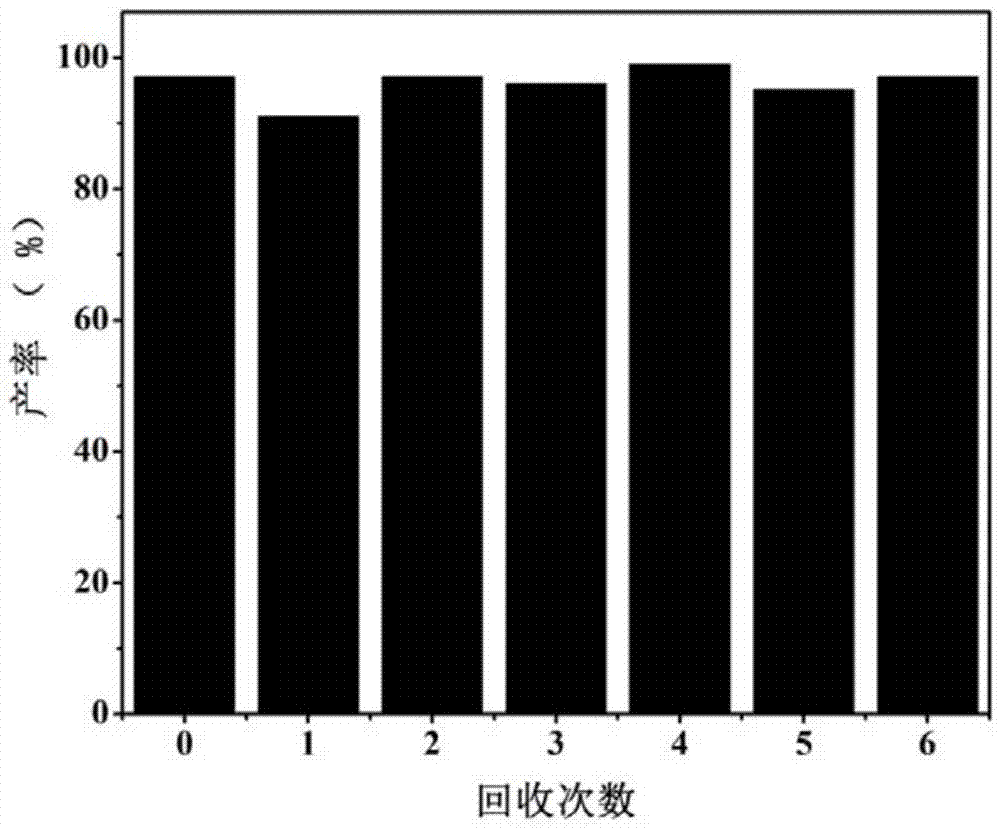

[0080] (2) Suzuki-Miyaura coupling reaction catalyzed by supported Pd organic molecular cages:

[0081] Dissolve Pd-loaded organic molecular cages (5 mg) in EtOH:H in a reaction tube 2 O=10:1 mixed solvent (4.4ml). Add 4-iodoanisole (47 mg), phenylboronic acid (37 mg), K 2 CO 3 (83 mg). After 3 deoxygenation by freezing-pump-thawing method, react at 50°C for 24h. After most of the solvent in the reaction solution was removed, the precipitation and diethyl ether we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com