Acrylic acid modified hot-melt pressure-sensitive adhesive for bearing adhesive tape and preparation method of acrylic acid modified hot-melt pressure-sensitive adhesive

A technology of hot-melt pressure-sensitive adhesive and acrylic, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve problems such as poor aging resistance, troublesome use, and large environmental pollution, and achieve aging resistance Good performance, low cost of use, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

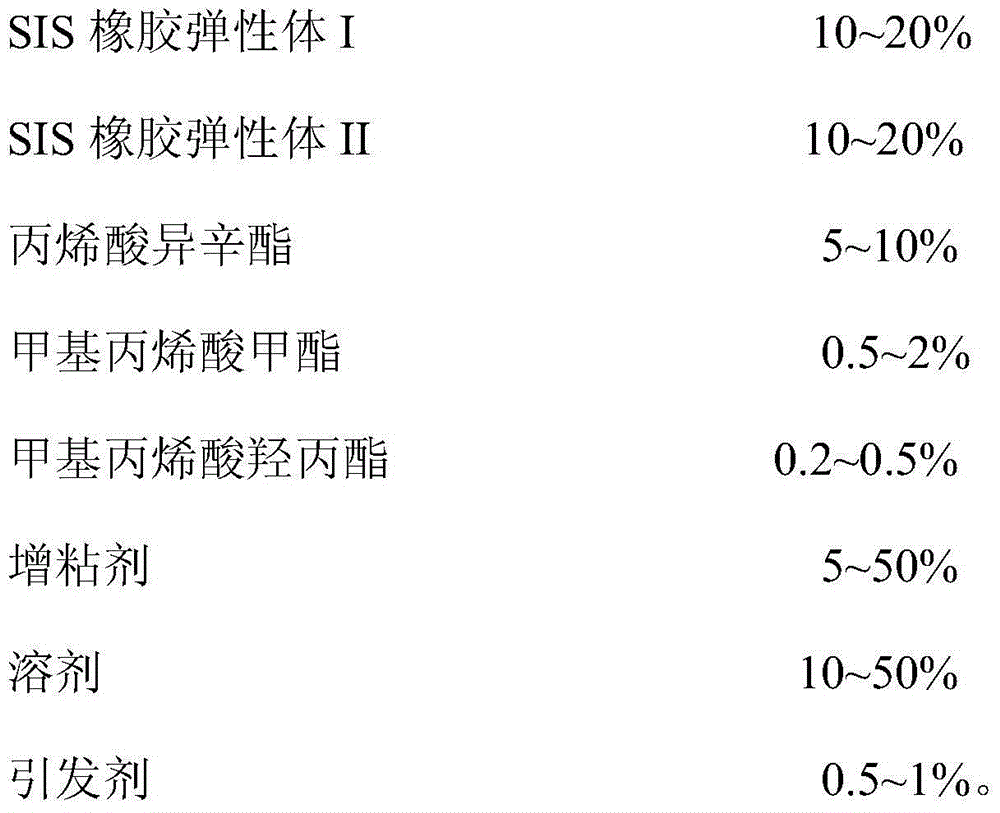

[0031] An acrylic-modified hot-melt pressure-sensitive adhesive for load-bearing tapes of the present invention comprises the following raw materials in mass percent:

[0032]

[0033] The average molecular weight of the SIS rubber elastic body I in this embodiment is 400,000, and the average molecular weight of the SIS rubber elastic body II is 300,000.

[0034] The terpene resin in this embodiment is SBS, and the SBS is a styrene-butadiene-styrene block copolymer.

[0035] A preparation method of an acrylic modified hot-melt pressure-sensitive adhesive for a load-bearing adhesive tape, comprising the following processing steps:

[0036] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0037] Step B, add SIS rubber elastic body I, SIS rubber elastic body II, toluene with 40% of the total amount of toluene and ethyl acetate with 40% of the total amount of ethyl acetate into the first reaction kettle, heat ...

Embodiment 2

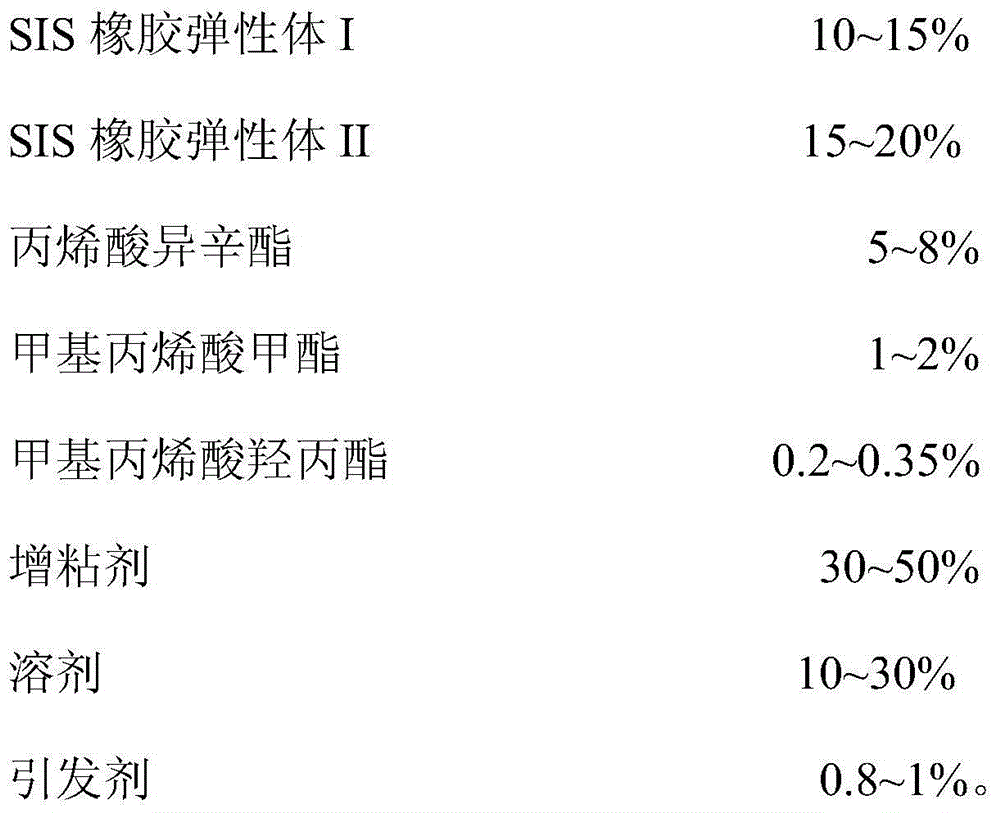

[0043] An acrylic-modified hot-melt pressure-sensitive adhesive for load-bearing tapes of the present invention comprises the following raw materials in mass percent:

[0044]

[0045]

[0046] The average molecular weight of the SIS rubber elastic body I in this embodiment is 300,000, and the average molecular weight of the SIS rubber elastic body II is 150,000.

[0047] The terpene resin in this embodiment is SBR, and the SBR is styrene-styrene-butadiene rubber.

[0048] A preparation method of an acrylic modified hot-melt pressure-sensitive adhesive for a load-bearing adhesive tape, comprising the following processing steps:

[0049] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0050] Step B. Add SIS rubber elastic body I, SIS rubber elastic body II, toluene with 50% of the total amount of toluene, and ethyl acetate with 50% of the total amount of ethyl acetate into the first reaction kettle, and...

Embodiment 3

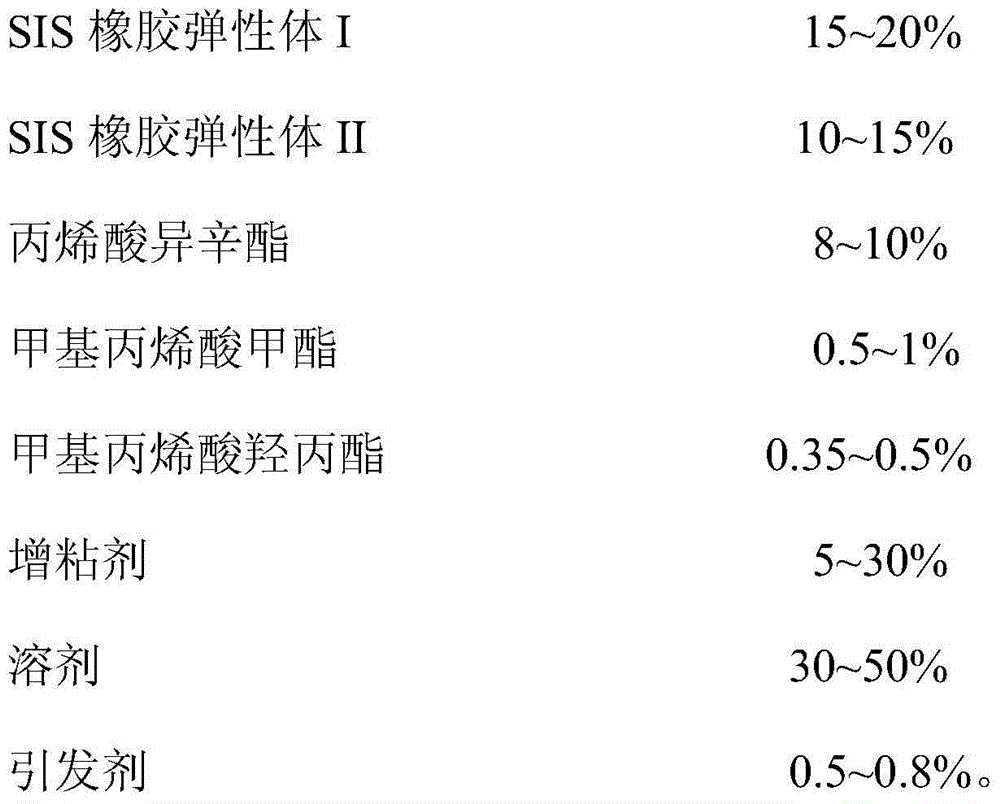

[0056] An acrylic-modified hot-melt pressure-sensitive adhesive for load-bearing tapes of the present invention comprises the following raw materials in mass percent:

[0057]

[0058] The average molecular weight of the SIS rubber elastic body I in this embodiment is 350,000, and the average molecular weight of the SIS rubber elastic body II is 250,000.

[0059] The terpene resin in this embodiment is SBS, and the SBS is a styrene-butadiene-styrene block copolymer.

[0060] A preparation method of an acrylic modified hot-melt pressure-sensitive adhesive for a load-bearing adhesive tape, comprising the following processing steps:

[0061] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0062] Step B, add SIS rubber elastic body I, SIS rubber elastic body II, toluene with a total amount of 40% of toluene, and ethyl acetate with a total amount of ethyl acetate of 40% into the first reaction kettle, heat to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com