Apparatus for high-temperature creep test and stress relaxation test of rubber elastomer

A rubber elastic body and high-temperature creep technology, which is applied in the field of rubber elastic body high-temperature creep test and stress relaxation test device, can solve the problems of single function and non-compliance with the action mode of rubber seals, etc., to achieve uniform force, The effect of saving experimental costs and accurate data results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

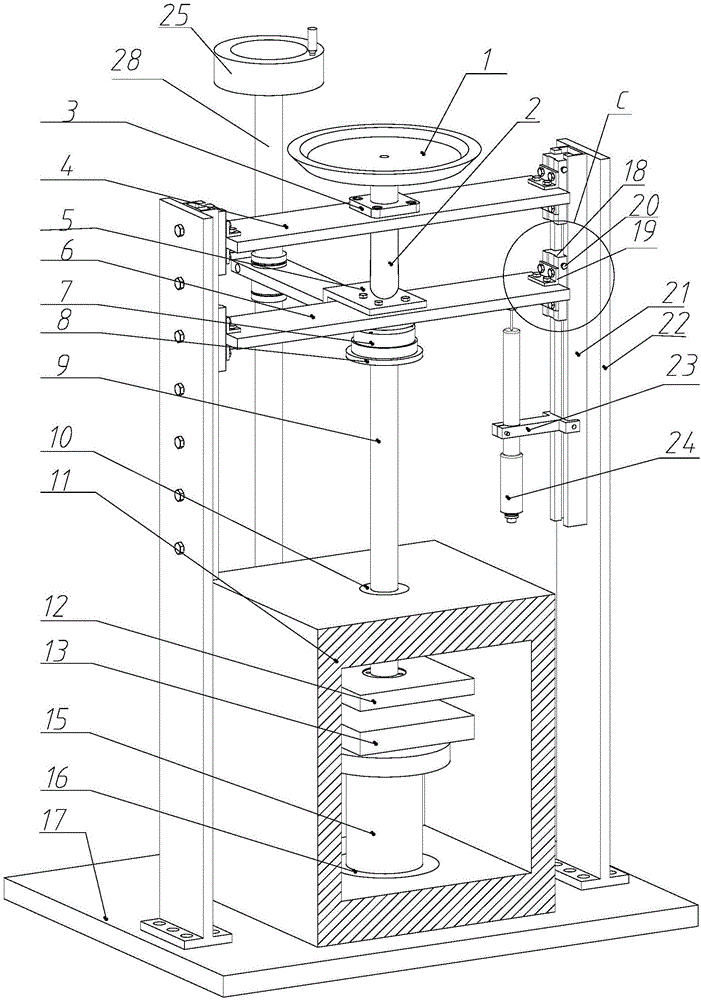

[0037] As shown in the figure, a device for high-temperature creep test and stress relaxation test of rubber elastic body includes a frame, and the frame is provided with a temperature control part and a stress loading part, and the stress loading part is located at a temperature directly above the control section;

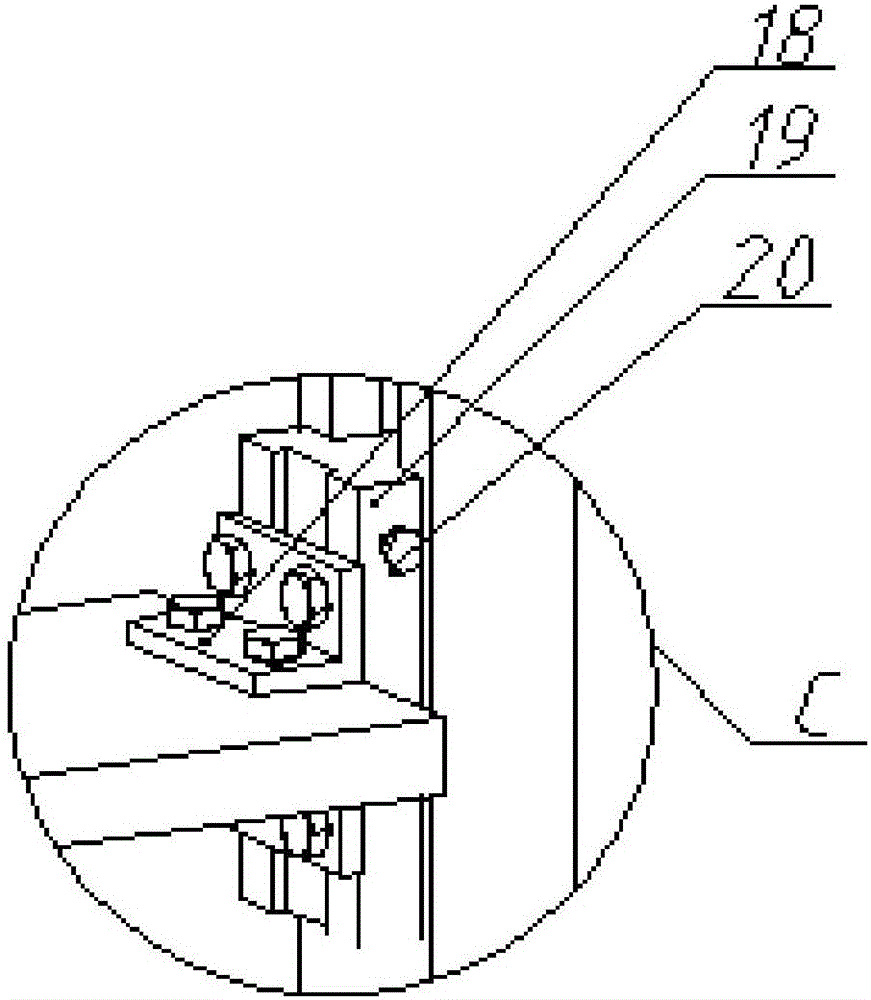

[0038] Described frame comprises the base 17 that is arranged horizontally and the side plate 22 that is vertically arranged on both sides of base 17, and described temperature control part comprises the high temperature test box 11 that is fixed on the base 17, is provided with for clamping in the high temperature test box 11 A clamp for rubber elastic body; the clamp includes an upper platen 12 and a lower platen 13 facing up and down, the upper platen 12 is horizontally suspended in the high temperature test chamber 11 through the connecting rod 9, the lower platen 13 is movably installed in the high temperature test chamber 11, the upper platen The gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com