Cathode active material, cathode, and non-aqueous electrolyte secondary battery

A positive active material, positive electrode technology, applied in non-aqueous electrolyte batteries, active material electrodes, secondary batteries, etc., can solve the problems of capacity deterioration, difficulty in obtaining battery capacity, shortening battery life, etc., to suppress the increase in internal resistance, The effect of excellent charge/discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0039] (1-1) Positive electrode active material

[0040] According to the positive electrode active material used in the secondary battery according to the first embodiment of the present invention, the coating layer contains a halogen element X and at least one selected from Groups 2 to 16 of the periodic table and is different from the compound contained in the matrix particle. The element M, which is a main transition metal element in the oxide particles, is provided on at least a part of the composite oxide particles, and the element M and the halogen element X exhibit different distribution states in the coating layer.

[0041] [Composite oxide particles]

[0042] The composite oxide particle used as the matrix particle is a lithium-containing transition metal oxide containing at least lithium and one or more transition metals, and is not particularly limited as long as it can intercalate and deintercalate lithium. However, from the viewpoint of achieving a large capacit...

no. 2 approach

[0125] (2-1) Positive electrode active material

[0126] As the positive electrode active material, a material similar to the positive electrode active material described in the first embodiment can be used.

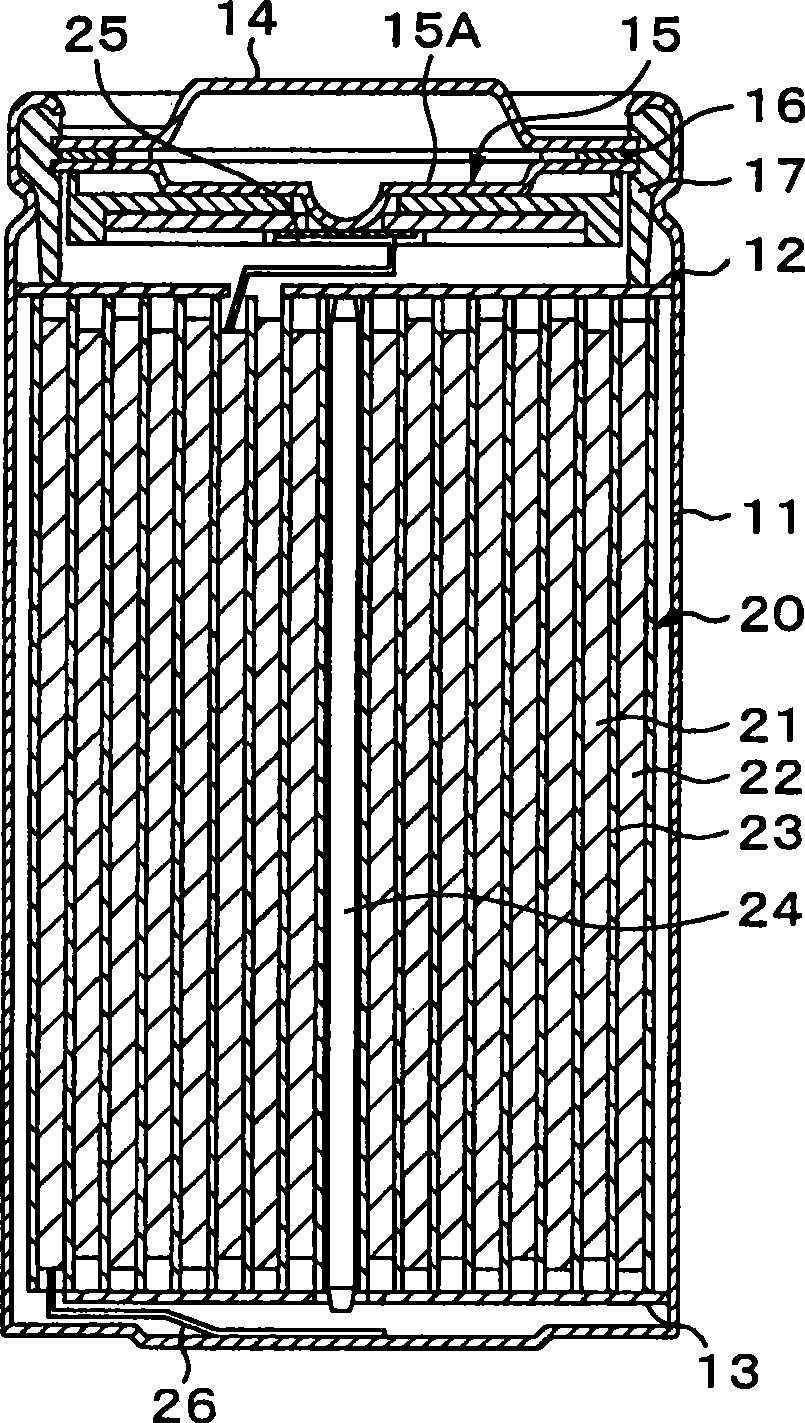

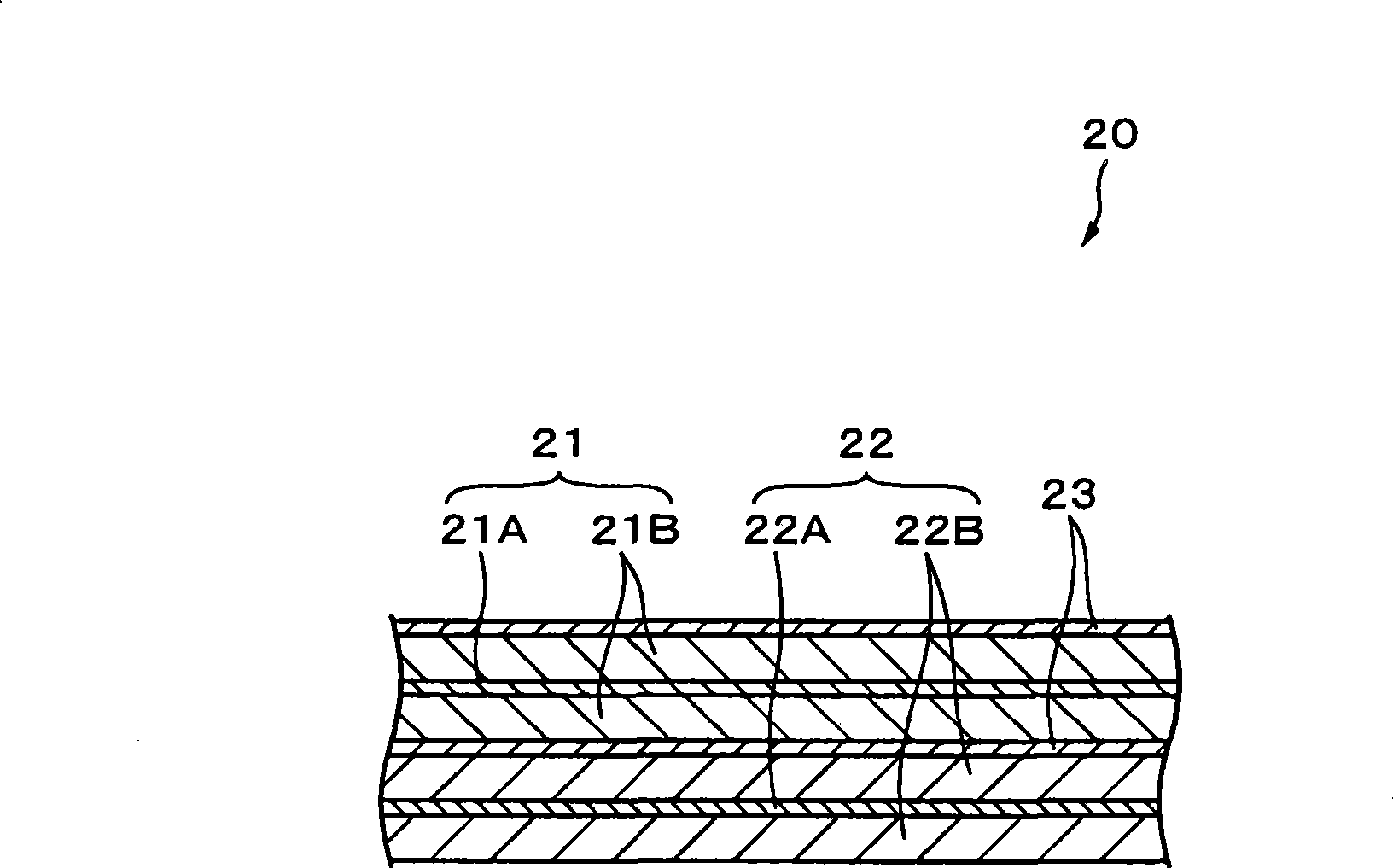

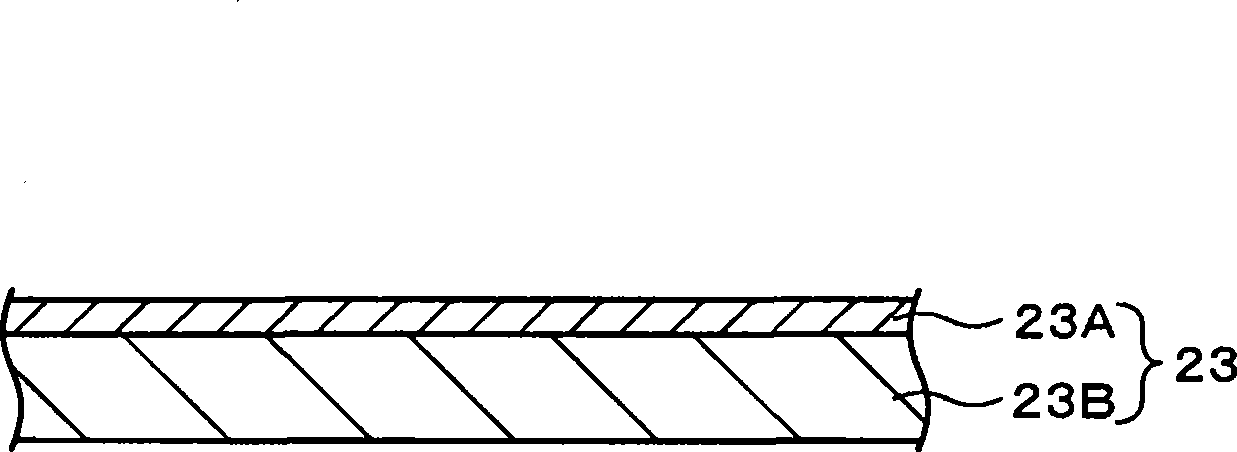

[0127] (2-2) Configuration of secondary battery

[0128] Figure 5 The configuration of the secondary battery according to the second embodiment is shown. This secondary battery is a so-called laminated film type secondary battery. The wound electrode member 30 to which the positive electrode lead 31 and the negative electrode lead 32 have been connected is enclosed in a film-shaped case member 40 .

[0129] Each of the positive electrode lead 31 and the negative electrode lead 32 is led from the inside to the outside of the case member 40 in the same direction, for example. The cathode lead 31 is made of, for example, a metal material such as aluminum Al, stainless steel SUS, or the like. The negative electrode lead 32 is made of, for example, a metal material such...

Embodiment 1

[0147] [Preparation of positive electrode]

[0148] The preparation method of the positive electrode active material will be described below. First, lithium cobalt oxide LiCoO with an average diameter equal to 13 μm measured by the laser light scattering method 2 Composite oxide particles used as matrix particles were prepared. Next, as the cladding layer material, manganese carbonate MnCO 3 Weigh and mix into LiCoO 2 The atomic ratio of cobalt Co:manganese Mn=100:2. Next, lithium cobalt oxide LiCoO was synthesized by using mechanochemical equipment 2 and manganese carbonate MnCO 3 The mixed powders were treated for 1 h and treated with MnCO 3 Coated Lithium Cobalt Oxide LiCoO 2 surface, thus forming a roasted precursor. The temperature of the fired precursor was increased at a rate of 3 °C / min. The calcined precursor was heat-treated at 900 °C for 3 hours, and then cooled in order to obtain a uniform distribution of manganese Mn in lithium cobalt oxide LiCoO 2 parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com