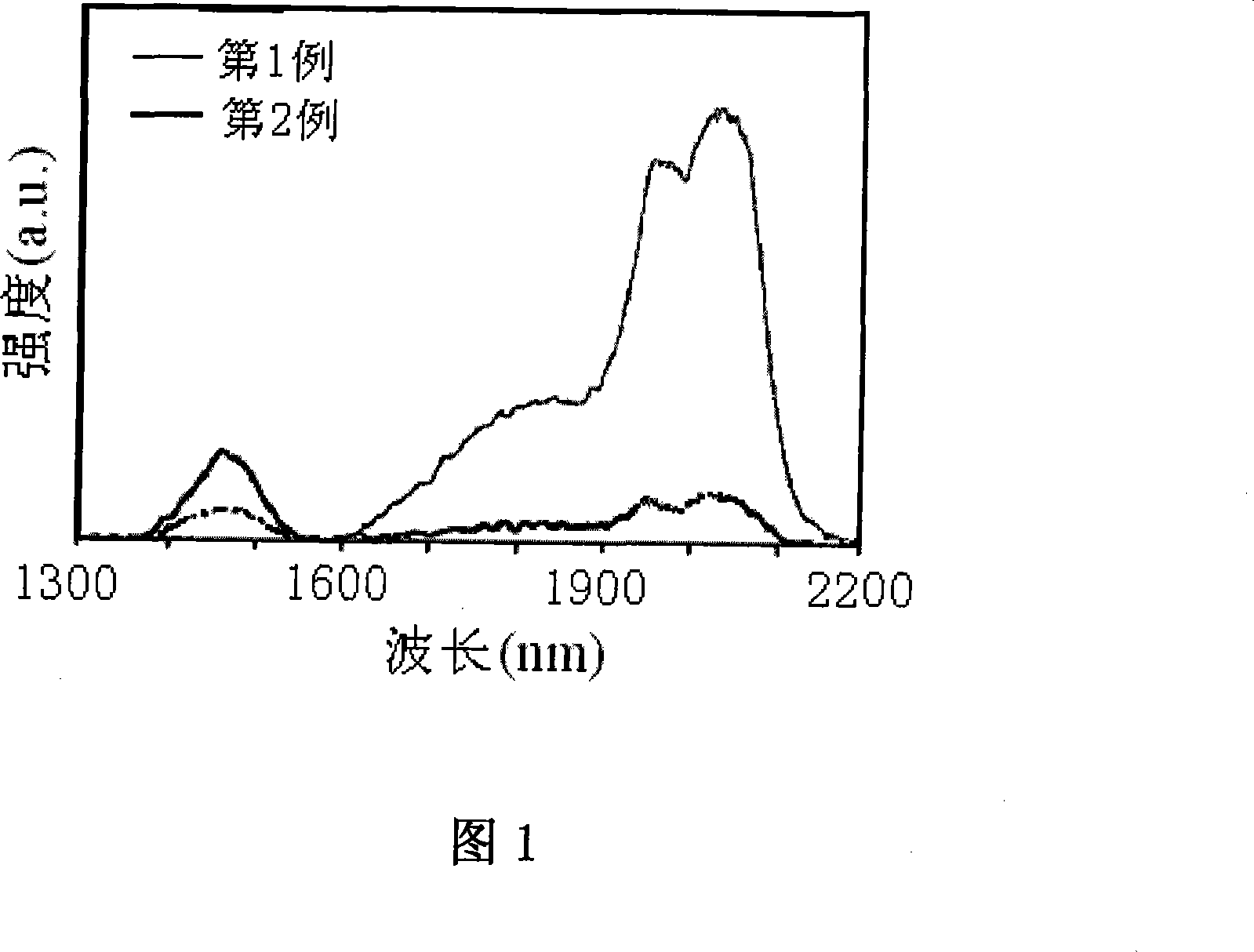

2ª–m band light-emitting oxyhalide tellurite glasses

An oxyhalotellurite and glass technology, applied in the field of glass, can solve the problems of poor chemical stability and mechanical strength preparation conditions, and achieve the effects of low cost, good glass-forming performance and water resistance, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

[0023] The following table enumerates the composition formula of 7 specific embodiments of the glass of the present invention and the thermal characteristic temperature of the glass. These embodiment glasses are all melted by common melting method, common muffle furnace and common water removal process. The thermal characteristic temperature of the glass obtained through testing is also listed in the table and the thermal characteristic temperature of the obtained glass. Where Tg is the glass transition temperature, Tx is the crystallization initial temperature, ΔT=Tx-Tg. But the present invention is not limited only to the glass composition formulations in the table below.

[0024] Case 1

Case 2

Case 3

Case 4

Case 5

Case 6

Case 7

Glass

glass

Group

Minute

TeO 2

40

55

60

65

70

8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com