White LED light source and manufacturing method of phosphor thereof

A technology of LED light source and phosphor, applied in the direction of light source, electric light source, optical element for changing the spectral characteristics of emitted light, etc. The problem of uneven thickness of the phosphor coating layer, etc., achieves the effects of stable luminous performance, low cost, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation method of phosphor 2 using borate as the parent body, its components and mole percentages are:

[0068] B 2 o 3 -30mol%,

[0069] ZnO-38mol%,

[0070] P 2 o 5 -30mol%,

[0071] AgNO 3 The doping amount is 2mol%.

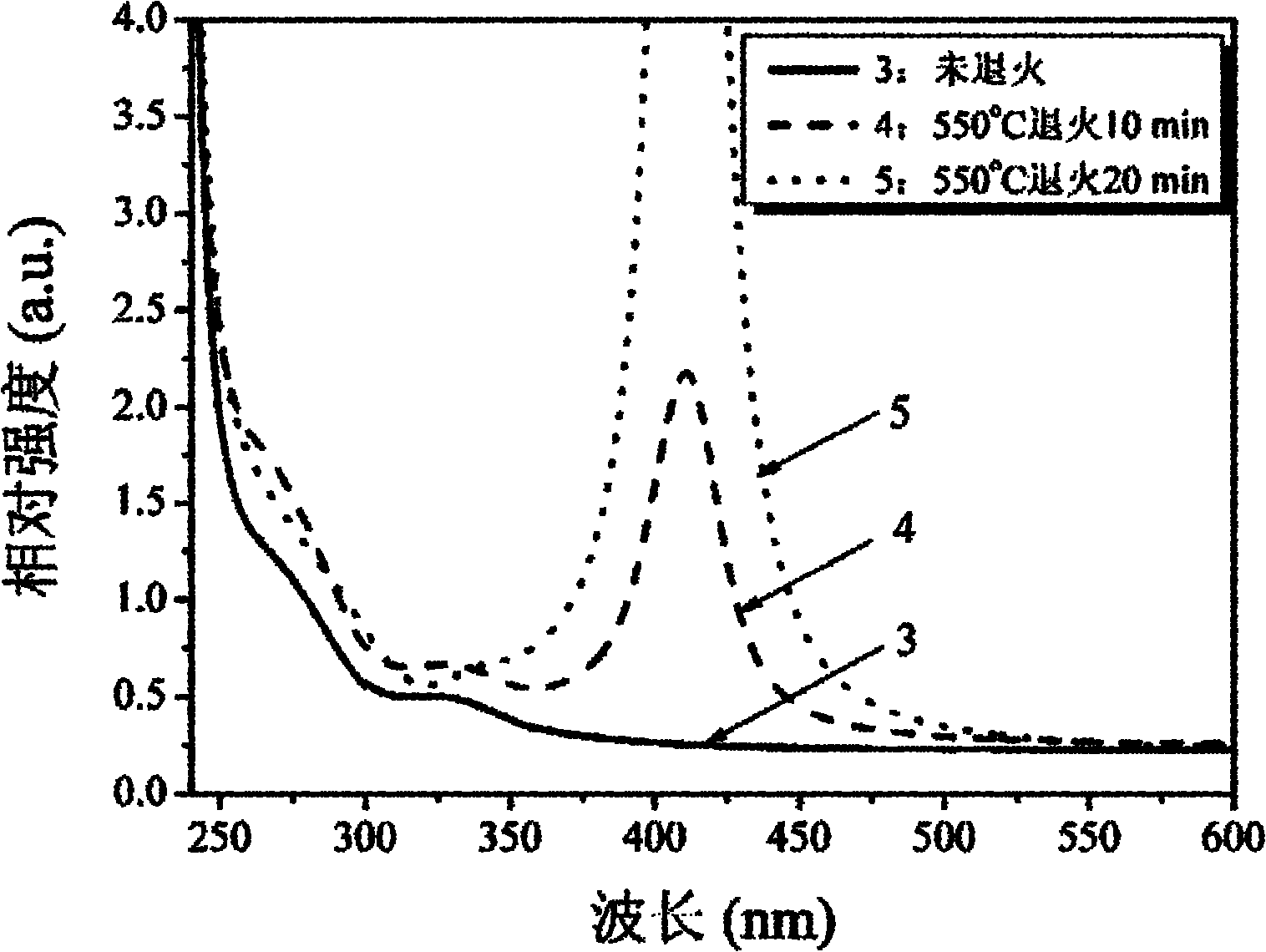

[0072] First weigh B according to the above chemical dosage ratio 2 o 3 , P 2 o 5 , ZnO and AgNO 3 raw materials, and grind to mix well. Put the uniformly mixed raw materials into a corundum crucible, heat at 1100°C and keep the temperature constant for 30 minutes, pour the molten liquid onto the preheated copper mold, and after forming primary glass, anneal in an electric furnace at 550°C for 10-60 minutes respectively, then it can be Metallic silver nanoparticles are grown in the glass, and the number and particle size of the generated metallic silver nanoparticles can be adjusted by changing the annealing time. Finally, the final glass obtained is cut and polished to a size of 10×10×1mm 3 sample. Such as figure 2 Shown is the...

Embodiment 2

[0075] The preparation method of phosphor 2 using germanate as the matrix, its components and molar percentages are:

[0076] GeO 2 -60mol%,

[0077] PbO-20mol%,

[0078] BaO-10mol%,

[0079] K 2 O-9.8mol%,

[0080] AgNO 3 The doping amount is 0.2mol%.

[0081] First weigh GeO according to the above chemical dosage ratio 2 , PbO, BaO, K 2 CO 3 and AgNO 3 raw materials, and grind to mix well. Put the uniformly mixed raw materials into a corundum crucible, heat at ~1100°C and keep the temperature constant for 30 minutes, pour the molten liquid onto the preheated copper mold to form primary glass, anneal in an electric furnace at 450°C to grow metallic silver nanoparticles, Finally the resulting final glass is cut and polished to make 10×10×1mm 3 sample. The results of the absorption spectrum test show that the sample has a strong metallic silver nanoparticle plasmon resonance absorption peak at around 450nm in the blue light band. By changing GeO 2 , PbO, BaO and ...

Embodiment 3

[0084] The preparation method of phosphor 2 using borate as the parent body, its components and mole percentages are:

[0085] B 2 o 3 -80mol%,

[0086] ZnO-10mol%,

[0087] Na 2 O-9.8mol%,

[0088] AgNO 3 The doping amount is 0.2mol%.

[0089] First weigh B according to the above chemical dosage ratio 2 o 3 , ZnO, Na 2 CO 3 and AgNO 3 raw materials, and grind to mix well. Put the uniformly mixed raw materials into a corundum crucible, heat at ~1100°C and keep the temperature constant for 30 minutes, pour the molten liquid into the preheated copper mold to form primary glass, and then anneal in an electric furnace at 450°C to grow metallic silver nanoparticles , and finally cut and polish the resulting final glass to make 10×10×1mm 3 sample. The results of the absorption spectrum test show that the sample has a strong metal silver nanoparticle plasmon resonance absorption peak at around 420nm in the blue light band. by changing B 2 o 3 , ZnO and Na 2 The rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com