Preparation method of tellurate transparent fluorescent glass for LED (light emitting diode) illumination

A technology for LED lighting and fluorescent glass, which is applied in the field of preparation of tellurite transparent fluorescent glass for LED lighting, can solve the problems of complex preparation process, low sintering temperature, poor transparency, etc., and achieves simple operation process, easy mass production, The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] will analyze pure TeO 2 、Na 2 O, ZnO, B 2 o 3 Each component is 60mol% TeO in terms of mole fraction 2 , 20mol%Na 2 O, 10mol% ZnO, 10mol% B 2 o 3 ,, and mass fraction 6wt% phosphor (in TeO 2 、Na 2 O, ZnO and B 2 o 3 After being weighed accurately, place it in an agate mortar, grind it evenly, place it in a corundum crucible, put it in a muffle furnace at 550°C for melting for 1 hour, and then pour the glass melt into a cast iron at 200°C Perform annealing treatment on the mold, and take out the fluorescent glass when the temperature drops to room temperature.

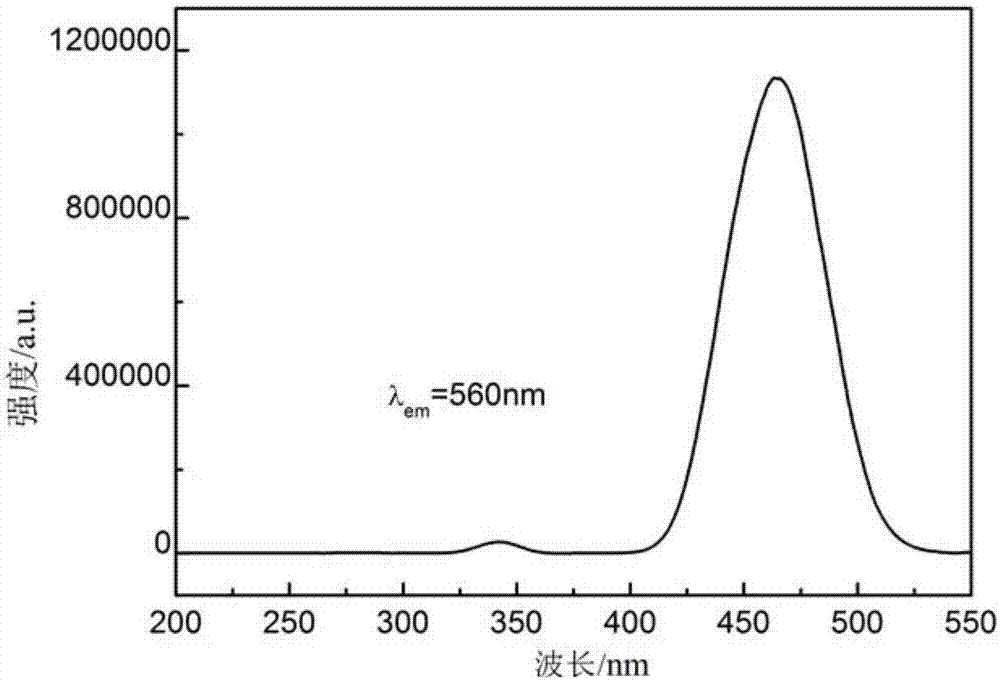

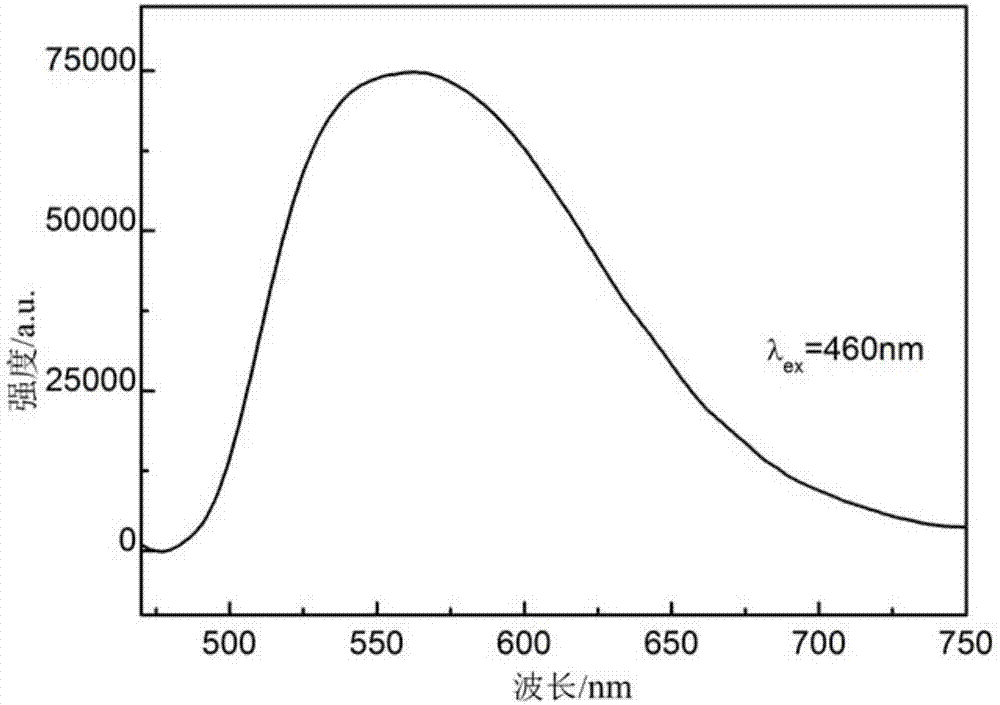

[0040] Adopt fluorescence spectrometer (FLS8900, British Edinburgh Instruments company) to measure the fluorescent glass of above-mentioned gained, the spectrogram of gained is as follows figure 2 , image 3 As shown, using Hangzhou Yuanfang STC4000 fast spectrometer to couple the fluorescent glass with a 460nm blue light chip to emit bright white light, as shown in Figure 4 shown. Under the excitat...

Embodiment 2

[0043] will analyze pure TeO 2 、Na 2 O, ZnO, B 2 o 3 Each component is 60mol% TeO in terms of mole fraction 2 , 20mol% Na 2 O, 10mol% ZnO, 10mol% B 2 o 3 , and the mass fraction of 8wt% phosphor (in TeO 2 、Na 2 O, ZnO and B 2 o 3 After being weighed accurately, place it in an agate mortar, grind it evenly, place it in a corundum crucible, put it in a muffle furnace at 550°C for melting for 1 hour, and then pour the glass melt into a cast iron at 200°C Perform annealing treatment on the mold, and take out the fluorescent glass when the temperature drops to room temperature.

[0044] Adopt fluorescence spectrometer (FLS8900, British Edinburgh Instruments company) to measure the fluorescent glass of above-mentioned gained, the emission spectrogram of gained is as follows Figure 6 , Figure 7 As shown, using Hangzhou Yuanfang STC4000 fast spectrometer to couple the fluorescent glass with a 460nm blue light chip to emit bright white light. Under the excitation of 460n...

Embodiment 3

[0046] will analyze pure TeO 2 、Na 2 O, ZnO, B 2 o 3 Each component is 60mol% TeO in terms of mole fraction 2 , 20mol% Na 2 O, 10mol% ZnO, 10mol% B 2 o 3 , and the mass fraction of 10wt% phosphor (in TeO 2 , Na 2 O, ZnO, B 2 o 3 After being weighed accurately, place it in an agate mortar, grind it evenly, place it in a corundum crucible, put it in a muffle furnace at 550°C for melting for 1 hour, and then pour the glass melt into a cast iron at 200°C Perform annealing treatment on the mold, and take out the fluorescent glass when the temperature drops to room temperature.

[0047] Adopt fluorescence spectrometer (FLS8900, British Edinburgh Instruments company) to measure the fluorescent glass of above-mentioned gained, the emission spectrogram of gained is as follows Figure 8 , Figure 9 As shown, using Hangzhou Yuanfang STC4000 fast spectrometer to couple the fluorescent glass with a 460nm blue light chip to emit bright white light. Under the excitation of 460nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com