Polymer for electrooptical material, dispersed liquid crystal film and method for preparing polymer

A technology of dispersing liquid crystals and polymers, applied in the al field, can solve the problems of PDLC film hysteresis, high driving voltage, and low ratio, and achieve the effects of improving refractive index matching, increasing display contrast, and reducing interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A. Add 10 parts of 4-fluorostyrene, 0.0225 parts of dibenzoyl peroxide and 0.225 parts of benzyl-1-propionic acid-trithioester into 10ml of tetrahydrofuran, place in a 100ml three-necked flask, and pass nitrogen gas for 15min to remove oxygen in the system. Stir and react in an oil bath at 90°C to 110°C for 24 hours, precipitate with ethanol, filter with suction, and dry in vacuum to obtain the macromolecular initiator RAFT-FPS; the number average molecular weight of RAFT-FPS measured by GPC is 6300, and the molecular weight distribution is 1.32.

[0048] B. Take 0.032 parts of dibenzoyl peroxide, 10 parts of RAFT-FPS prepared in step A and 40 parts of methyl methacrylate (MMA) and add them to 50ml of tetrahydrofuran, and prepare the macroinitiator RAFT according to the same conditions as a. -FPS-PMMA; the number average molecular weight of RAFT-FPS-PMMA measured by GPC is 25500, and the molecular weight distribution is 1.34.

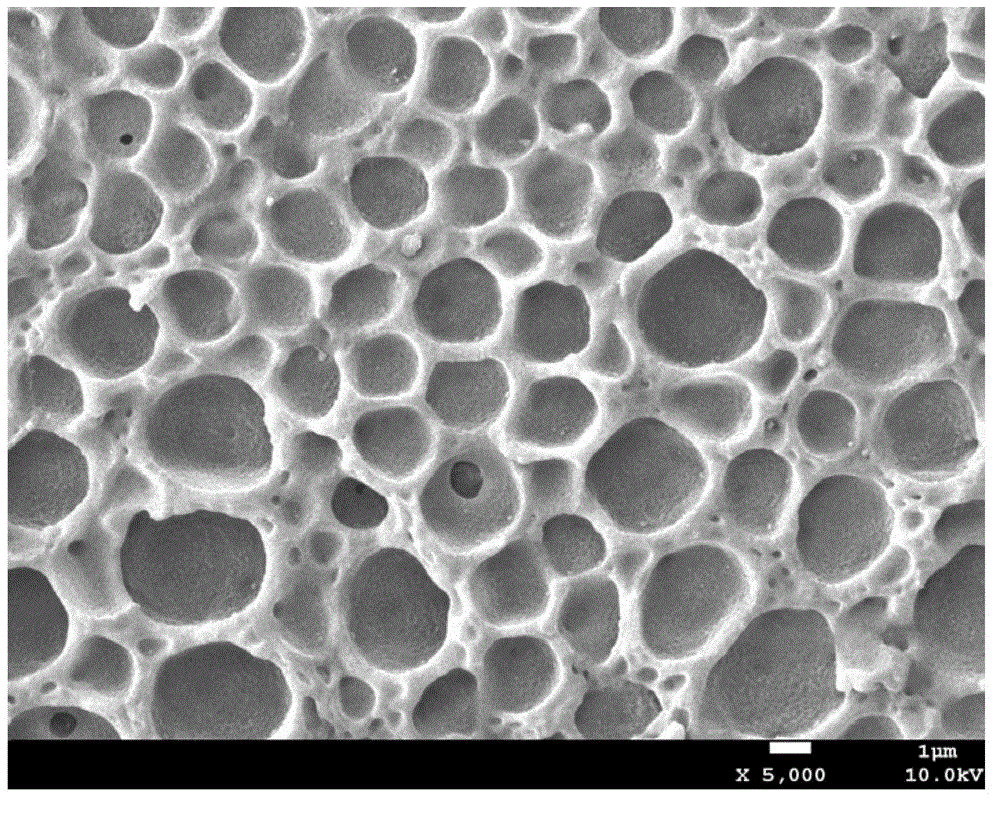

[0049] C. 50 parts by weight of macro...

Embodiment 2

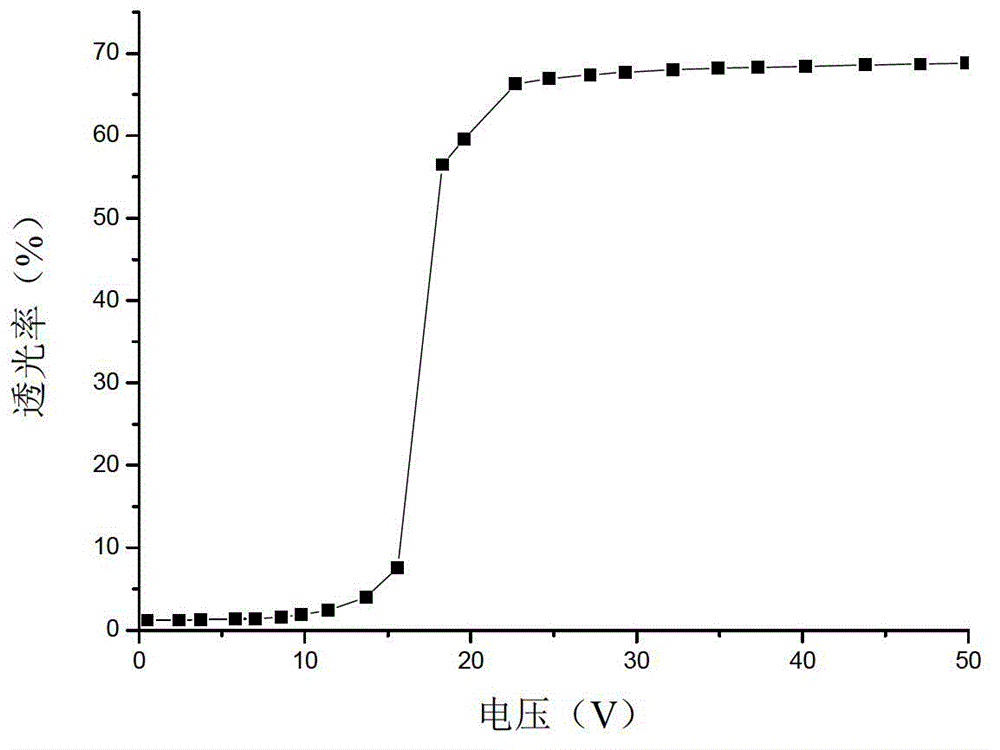

[0054] The macromolecular initiator RAFT-FPS-PMMA was synthesized according to the method in Example 1 and a PDLC film was fabricated. The preparation ratio and photocuring process of the photosensitive solution are the same as in Example 1, except that the formula for synthesizing the macroinitiator RAFT-FPS is: 10 parts of 4-fluorostyrene, 0.03 part of dibenzoyl peroxide, benzyl-1-propane 0.3 part of acid-trithioester and 10 ml of tetrahydrofuran. Electro-optical performance as attached Figure 4 As shown, the driving voltage of the obtained PDLC is 21V, and the light transmittance in the open state is 70.6%. The number average molecular weight of the polymer matrix of PDLC measured by GPC is 34200, and the molecular weight distribution is 1.36.

Embodiment 3

[0056] The macromolecular initiator RAFT-FPS-PMMA was synthesized according to the method in Example 1 and a PDLC film was fabricated. The preparation ratio of the photosensitive solution and the photocuring process are the same as in Example 1, except that the formula for synthesizing the macroinitiator RAFT-FPS-PMMA is: 0.025 parts of dibenzoyl peroxide, 15 parts of the macroinitiator RAFT-FPS, 60 parts MMA and 30ml tetrahydrofuran. The driving voltage of the obtained PDLC is 22V, and the light transmittance in the open state is 66.3%. The number average molecular weight of the polymer matrix of PDLC measured by GPC is 45700, and the molecular weight distribution is 1.35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com