Crown ether modified polyimide hybrid membrane and preparation method thereof

A polyimide and hybrid film technology, applied in the field of organic polymer material modification, can solve the problems of polyimide thermal stability and poor mechanical properties, and achieve easy slippage and increased elongation at break. , the effect of reducing the interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

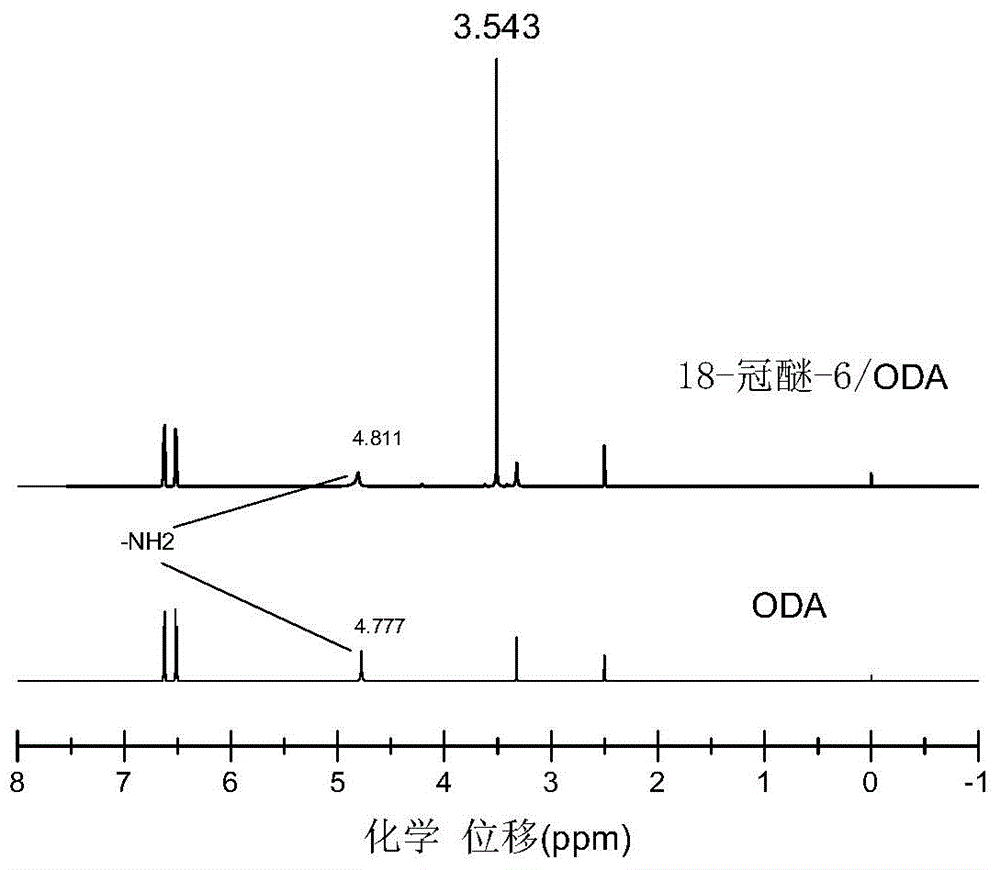

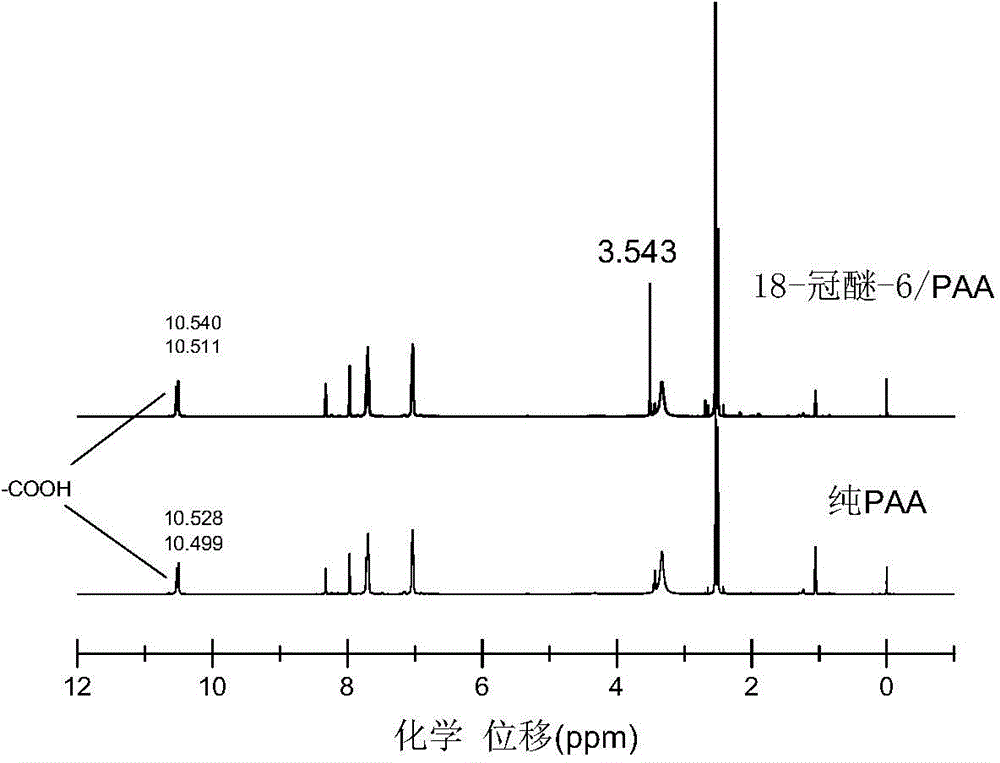

[0029] (1) Under 40% humidity, 32°C and mechanical stirring, nitrogen gas was introduced into a 50ml three-necked bottle, and 0.0040mol4,4'-diaminodiphenyl ether (ODA), 0.0016mol 18-crown-6 and 12g DMSO, after 18-crown-6 and ODA are completely dissolved, continue stirring for 1 hour to obtain 18-crown-6 / ODA clathrate solution; 18-crown-6 prepared with deuterated DMSO as solvent / ODA clathrate solution with pure ODA (in deuterated DMSO) 1 The comparison of H-NMR spectra is attached figure 1, it can be seen from the figure that after ODA interacts with 18-crown ether-6, the chemical shift of the hydrogen atom on the primary amine moves from 4.777ppm to 4.811ppm, while the chemical shift of the hydrogen atom on the benzene ring does not shift , still at 6.497 and 6.630ppm, the chemical shift (3.543ppm) of the hydrogen atom of the crown ether itself has not shifted, indicating that there is a strong hydrogen bond between the hydrogen on the ODA primary amine and the oxygen in 18-...

Embodiment 2

[0033] Under 45% humidity, 35°C and mechanical stirring, nitrogen gas was introduced, and 0.0045mol 2,4,6-trimethyl-m-phenylenediamine (TMPDA), 0.00045mol 18-crown-6 and 12g of NMP, until 18-crown-6 and TMPDA are completely dissolved, then continue to stir for 1.2 hours to obtain 18-crown-6 / TMPDA clathrate solution; 0.0049mol3,3',4,4'-di Divide benzophenone tetra-acid dianhydride (BTDA) into four equal parts, and add it to the above-mentioned three-necked flask every 28 minutes. After the addition of BPDA, continue to stir for 9 hours to obtain 18-crown-6 modified TMPDA-BPDA Type polyamic acid solution;

[0034] Take 9.5g of the above polyamic acid solution and spread it evenly on a clean glass sheet, and then place it in a vacuum drying oven to eliminate air bubbles for 4.5 hours; follow the set program to keep the temperature at 81°C for 1.2 hours, 102°C for 1.5 hours, Keep at 198°C for 1.3 hours and at 298°C for 2.1 hours for thermal imidization; after the treatment, cool ...

Embodiment 3

[0036] Under 40% humidity, 25°C, and mechanical stirring, nitrogen gas was introduced, and 0.0034mol 1,3-phenylenediamine (MPDA), 0.00068mol 18-crown-6 and 12g DMF were added to a 50ml three-necked flask to reach 18 -After crown ether-6 and MPDA are completely dissolved, continue stirring for 1.4 hours to obtain 18-crown ether-6 / MPDA clathrate solution; under mechanical stirring, 0.0034mol3,3',4,4'-benzophenone Tetraacid dianhydride (BTDA) is divided into four equal parts, and added to the above-mentioned three-necked bottle at intervals of 20 minutes. After the BTDA is added, continue to stir for 8 hours to obtain 18-crown-6 modified MPDA-BTDA type poly Amic acid solution;

[0037] Take 9g of the above polyamic acid solution and apply it evenly on a clean glass sheet, then place it in a vacuum drying oven to eliminate air bubbles under vacuum for 4 hours; keep the temperature at 82°C for 1.5 hours, 103°C for 1.3 hours, Keep at 192°C for 1.4 hours and at 295°C for 2.4 hours f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com