Three-layer antireflective film for solar battery and preparation method thereof

A technology for solar cells and multi-junction solar cells, which is applied in coatings, circuits, photovoltaic power generation, etc., can solve the problems of single-layer film anti-reflection ability limit and cannot reach high, and achieve good optical and chemical stability and combination And the effect of good firmness and small absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

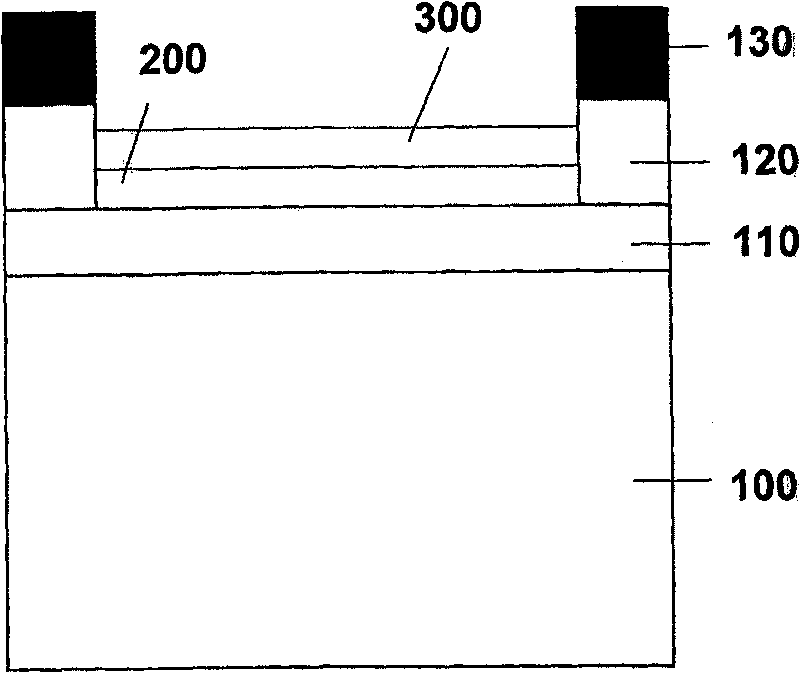

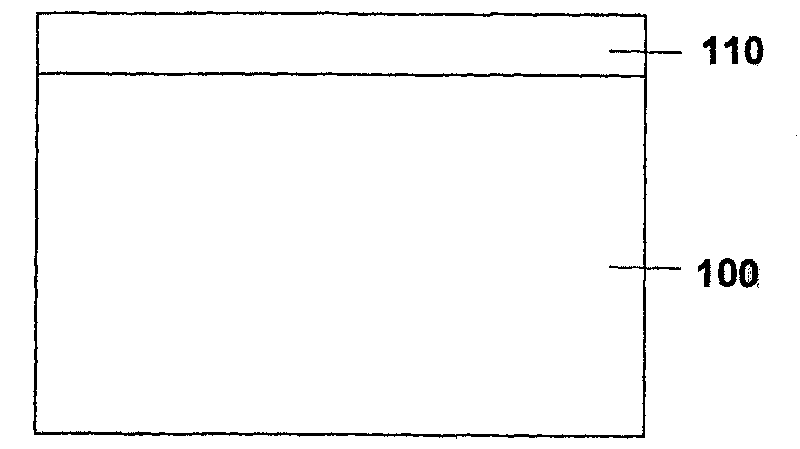

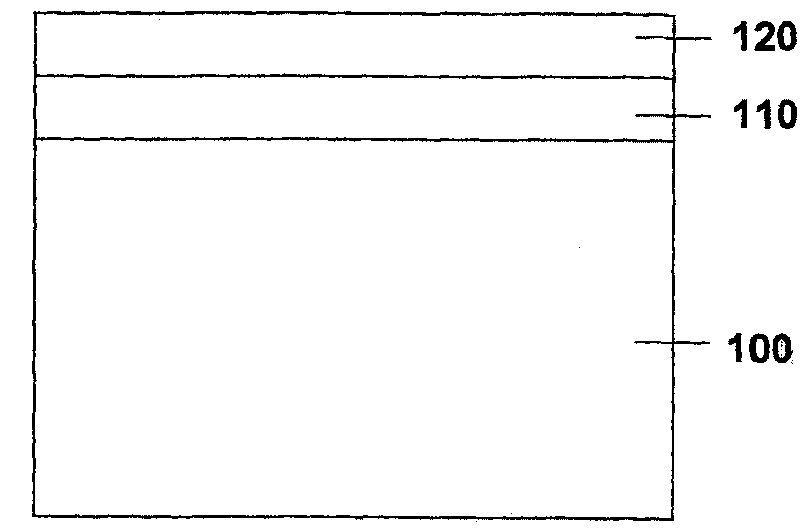

[0024] Such as figure 1 A three-layer solar cell anti-reflection film is shown, and the anti-reflection film is sequentially laminated on the GaInP / GaInAs / Ge multi-junction solar cell 100 to form a composite optical film. The refractive index of the first layer of anti-reflection film AlGaInP film 110 is 3.25, The thickness is 40nm; the second layer of anti-reflection coating Ta 2 o 5 The refractive index of the thin film 200 is 2.15 and the thickness is 70nm; the third anti-reflection film MgF 2 The thin film 300 has a refractive index of 1.38 and a thickness of 105 nm.

[0025] A kind of preparation method of three-layer solar cell anti-reflection film of the present invention, its steps are as follows:

[0026] First in the MOCVD system, grow the GaInP / GaInAs / Ge multi-junction solar cell until the GaInP top cell emitter 100; in the MOCVD system, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com