Yb3+ doped tellurate glass doubly coated fiber and preparing method thereof

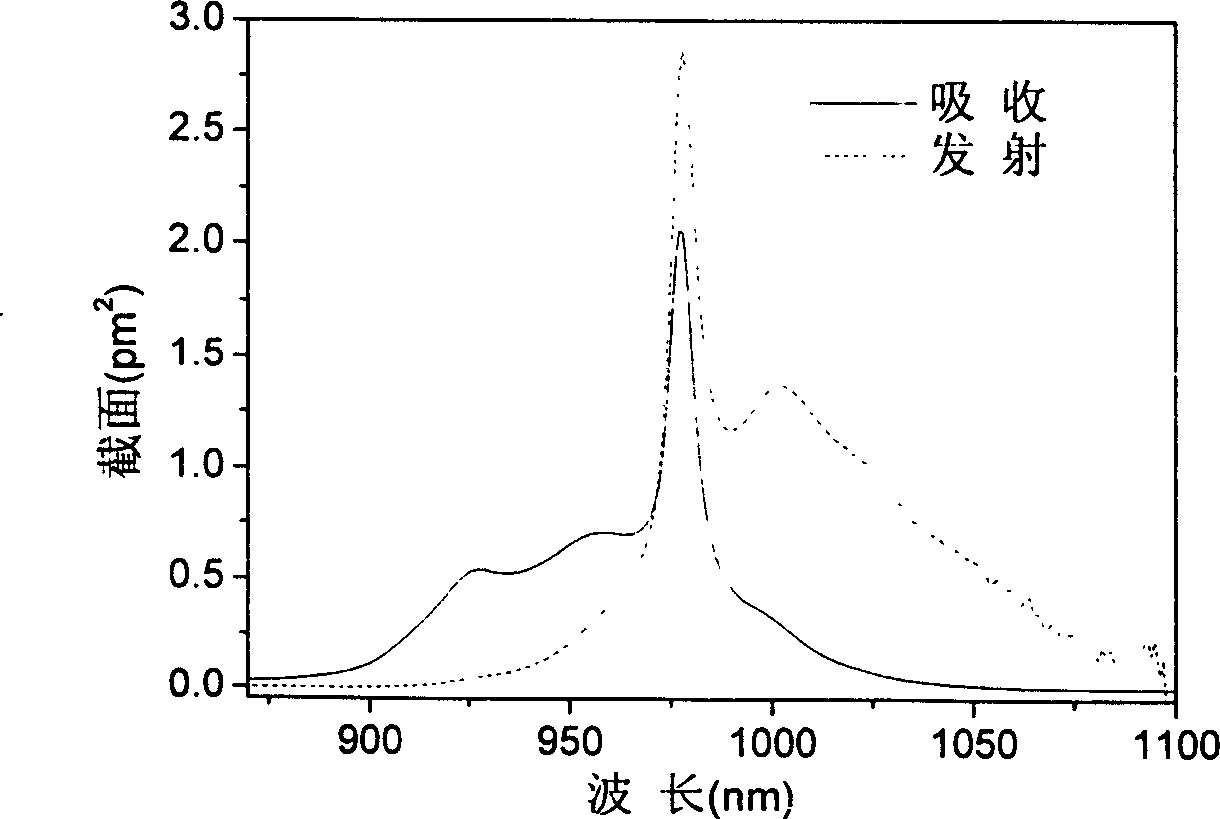

A technology of double-clad optical fiber and tellurite glass, applied in glass manufacturing equipment, optics, light guide, etc., can solve the problems of small adjustable range of double-clad optical fiber, ion clusters, affecting the absorption efficiency of pump light, etc. , to achieve the effect of large gain performance and tunable range, high rare earth doping concentration, and simple drawing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] (2) Preparation of fiber core and inner cladding glass. According to the above principles, select the formula in Table 1, mix the powdered raw materials evenly, and melt them in a quartz crucible or platinum crucible. The melting temperature is 700-900 ° C. The raw materials are completely melted. The liquid is poured on a preheated iron mold. Then quickly put the glass into the glass that has been heated to the glass transition temperature (T g ) in a nearby muffle furnace for annealing. The annealing process is: at the glass transition temperature (T g ) nearby for 2 hours, then cool down to 100°C at a rate of 2-5°C / hour, and then turn off the power of the muffle furnace to automatically cool down to room temperature. Remove the glass sample after complete cooling. Except for the different formulations, the core and inner cladding are melted in exactly the same way.

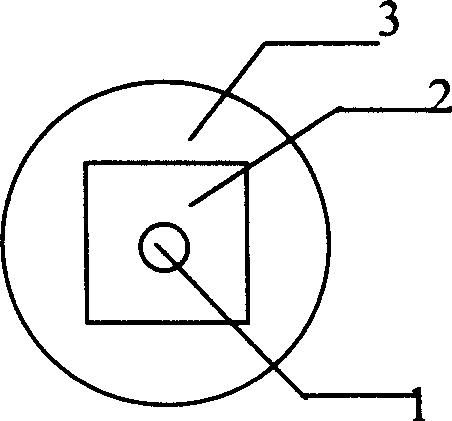

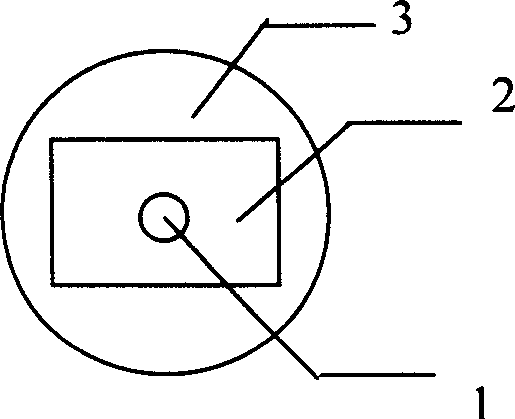

[0044] (3) Production of preforms. The above-prepared core glass is cut, ground, and polished i...

specific Embodiment

[0048] The first step: select a suitable fiber core and inner cladding formula (mol%), see Table 2;

[0049] The second step: the process of melting the core and inner cladding of tellurite glass: (1) Preparation of core glass: high-purity TeO 2 , ZnO, PbO, Na 2 O, K 2 O, La 2 o 3 and Yb 2 o 3 After the powdered raw materials are mixed evenly according to the core formula, they are placed in a platinum crucible and melted in a silicon carbide rod electric furnace. During the glass melting process, dry oxygen is introduced for atmosphere protection. melt

[0050] TeO 2

PbO

ZnO

La 2 o 3

K 2 o

Na 2 o

Yb 2 o 3

n

T f (℃)

No.

one

fiber

the core

65

20

5

4.5

0

5

0.5

2.092

442

Group

Inside

Bag

layer

65

18

5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com