Preparation method of wire drawing decorative film

A decorative film and wire drawing technology, which is applied in special decorative structures, decorative arts, and techniques for producing decorative surface effects, etc., can solve the problems of complex structure, high production cost, and complicated decorative film structure, and achieve simple wire drawing process, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

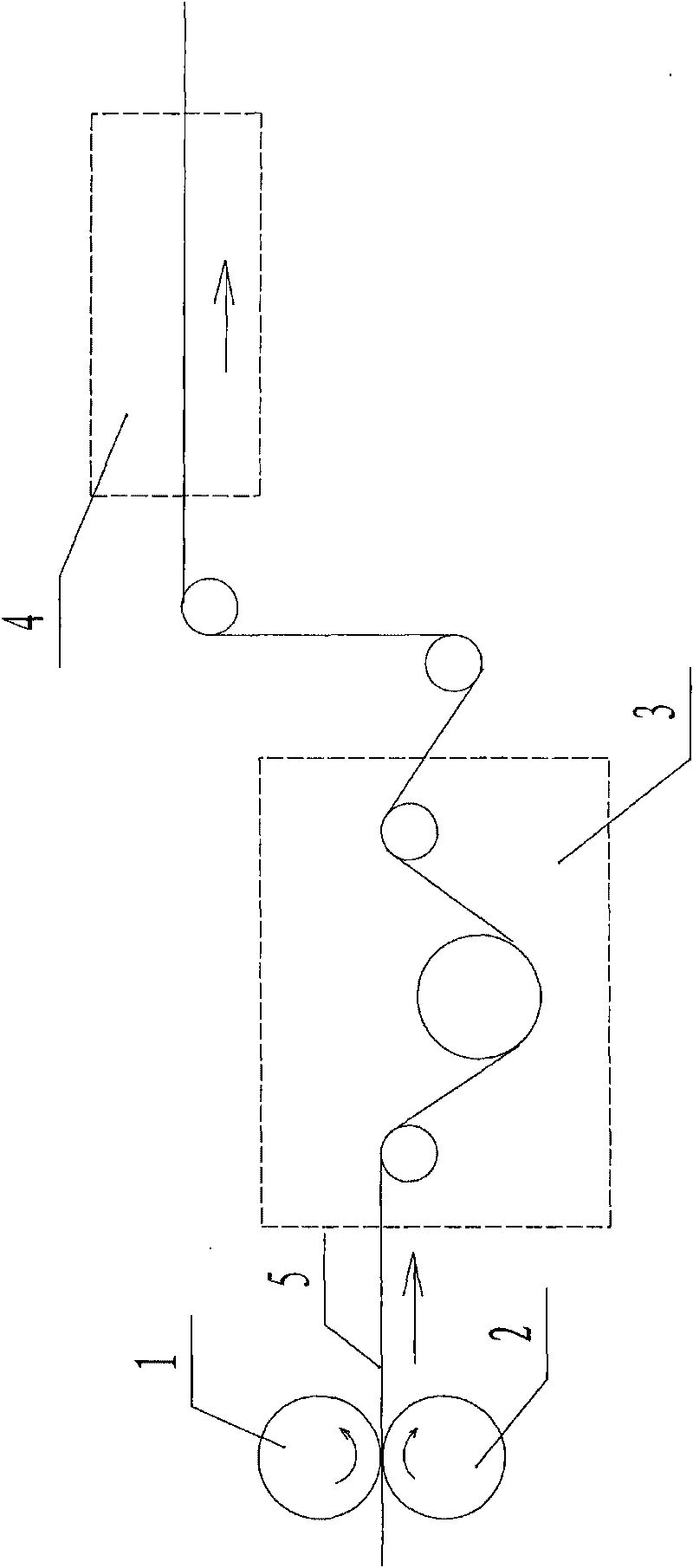

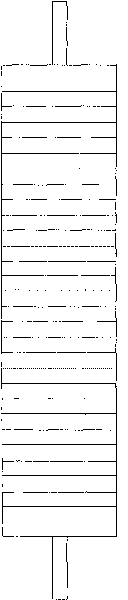

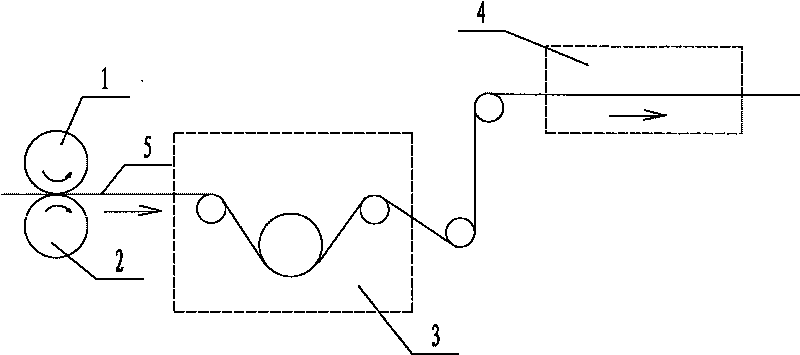

[0050] Using a 15 micron thick PET substrate, the surface of the PET substrate is drawn under the following conditions: the substrate speed is 80m / min, the upper roller is synchronized with the substrate, the speed is 80m / min, the lower roller and the upper roller are in the same direction , the speed is 20m / min (the speed difference is 60), the pressure difference between the upper roll and the lower roll is 0.4MPa, and the surface linear density of the lower roll is 10 / mm. Then, a multifunctional layer with a thickness of 2.0 microns was coated on the substrate by anilox roller coating.

[0051] A metal layer was vacuum-deposited on the multi-functional layer, and then an adhesive layer with a thickness of 3 microns was coated on the metal layer by anilox roller coating to obtain a brushed decorative film, and then the performance test was carried out.

Embodiment 2

[0053] Using a 20 micron thick PET substrate, the surface of the PET substrate is drawn under the following conditions: the substrate speed is 100m / min, the upper roller is synchronized with the substrate, the speed is 100m / min, the lower roller and the upper roller are in the same direction , the speed is 50m / min (the speed difference is 50), the pressure difference between the upper roller and the lower roller is 0.3MPa, and the surface linear density of the lower roller is selected as 15 / mm. Then, a multifunctional layer with a thickness of 2.0 microns was coated on the substrate by anilox roller coating.

[0054] A metal layer was vacuum-deposited on the multi-functional layer, and then an adhesive layer with a thickness of 3 microns was coated on the metal layer by anilox roller coating to obtain a brushed decorative film, and then the performance test was carried out.

Embodiment 3

[0056] Using a 30 micron thick PET substrate, the surface of the PET substrate is drawn under the following conditions: the substrate speed is 60m / min, the upper roller is synchronized with the substrate, the speed is 60m / min, the lower roller and the upper roller are reversed , the speed is 10m / min (the speed difference is 70), the pressure difference between the upper roller and the lower roller is 0.2MPa, and the surface linear density of the lower roller is selected as 100 / mm. Then, a multi-functional layer with a thickness of 2.0 microns was coated on the substrate by anilox roller coating.

[0057] A metal layer was vacuum-deposited on the multi-functional layer, and then an adhesive layer with a thickness of 3 microns was coated on the metal layer by anilox roller coating to obtain a brushed decorative film, and then the performance test was carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com