Preparation method and application of Mo-V-Te-Nb-O catalyst

A technology of mo-v-te-nb-o and catalyst, which is applied in the field of preparation of Mo-V-Te-Nb-O catalyst, can solve the problems of poisoning of experimental workers and further improvement of catalytic performance, and achieve good stability The effect of high reliability and repeatability, low price and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

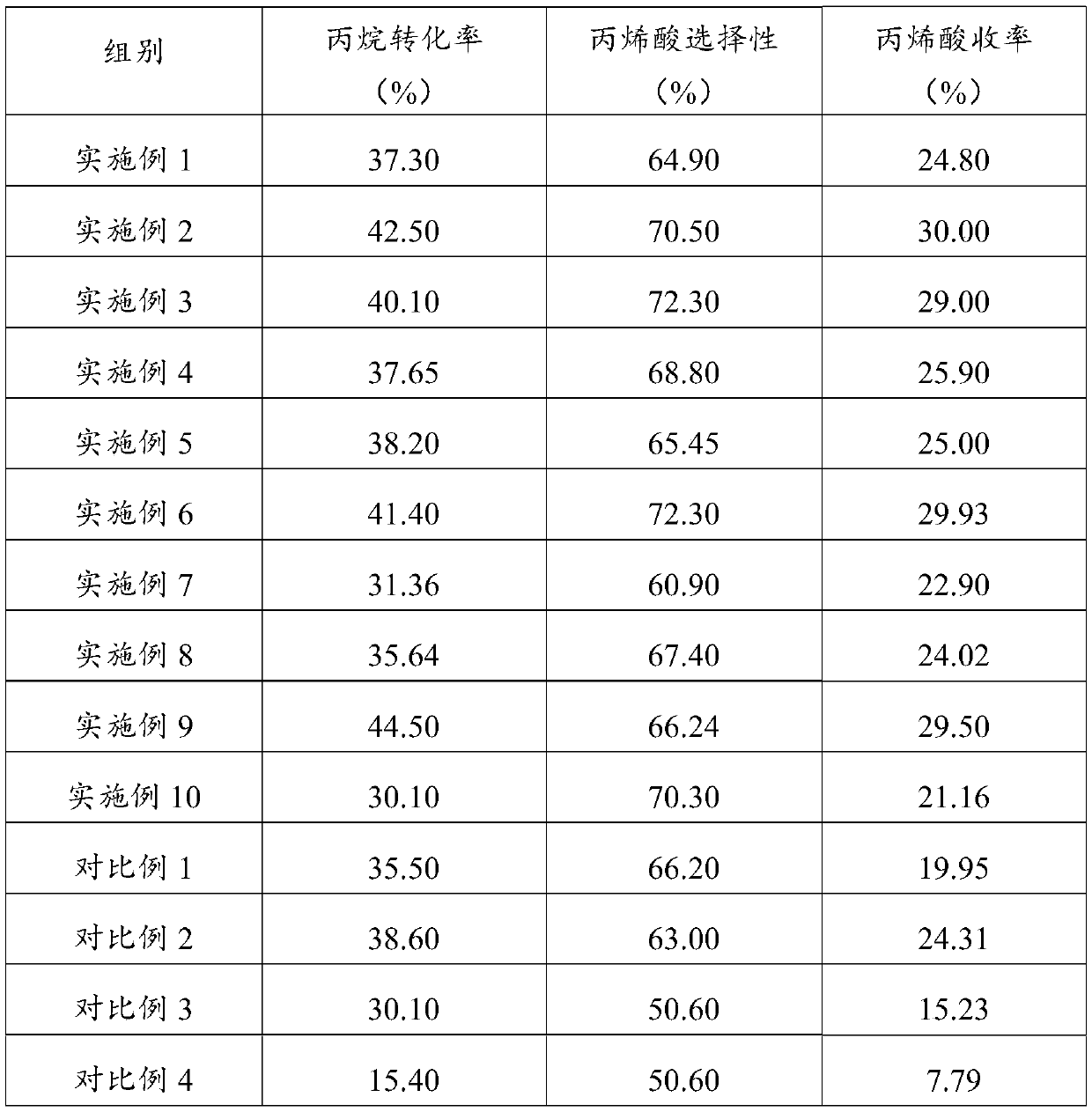

Examples

preparation example Construction

[0052] According to one aspect of the present invention, the preparation method of Mo-V-Te-Nb-O catalyst is provided, comprising the following steps:

[0053] Provide reduced metal tellurium obtained by reducing high-valent tellurium compounds with reducing agents;

[0054] Put the reduced tellurium metal, molybdenum source, vanadium source, and niobium source in a solvent to react, dry the product obtained by the reaction, and roast to obtain the Mo-V-Te-Nb-O catalyst;

[0055] Wherein, the reducing agent includes any one or a combination of at least two of sodium borohydride, potassium borohydride, ascorbic acid, sodium citrate or potassium citrate; the high-valent tellurium compound is Te 4+ compound or Te 6+ compound.

[0056] Specifically, different from the use of telluric acid as the source of tellurium in the preparation method of the existing Mo-V-Te-Nb-O catalyst, in the present invention, the reduced metal tellurium obtained by reducing the high-valent tellurium c...

Embodiment approach

[0074] As an optional embodiment of the present invention, the molybdenum source includes any one or a combination of at least two of ammonium dimolybdate, ammonium tetramolybdate or ammonium paramolybdate;

[0075] And / or, the vanadium source includes vanadyl sulfate and / or ammonium metavanadate;

[0076] And / or, the source of niobium includes niobium oxalate and / or ammonium niobium oxalate.

[0077] By limiting the specific types of molybdenum source, vanadium source and niobium source, each raw material has a good coordination relationship, so that the performance of the prepared Mo-V-Te-Nb-O catalyst is at a better level.

[0078] As an optional embodiment of the present invention, the preparation method of Mo-V-Te-Nb-O catalyst comprises the following steps:

[0079] Mix the reducing agent, high-valent tellurium compound and water, and reduce at 30-200°C for 0.5-72 hours to obtain reduced metal tellurium;

[0080] Mix the reduced metal tellurium with the molybdenum sour...

Embodiment 1

[0105] The present embodiment provides a kind of preparation method of Mo-V-Te-Nb-O catalyst, comprises the following steps:

[0106] (a) Mix 0.74g of reducing agent, 1.50g of high-valent tellurium compound with water, reduce at 40°C for 5h, and then wash to obtain reduced metal tellurium; wherein, the reducing agent is sodium borohydride, the high-valent tellurium compound is telluric acid, borohydrogenated The molar ratio of sodium to telluric acid is 3:1;

[0107] (b) Mix the reduced metal tellurium with 5.00 g of ammonium paramolybdate, 1.39 g of vanadyl sulfate and water, place it in an oscillating ultrasonic instrument for 0.5 h, and then carry out a reaction at 130 ° C for 8 h under stirring conditions to obtain a mixed solution;

[0108] Mix the mixed solution with 1.83g of niobium oxalate, and carry out the secondary reaction for 5h under the condition of stirring at 130°C. After aging the product obtained by the reaction for 5h at 50°C, carry out spray drying, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com