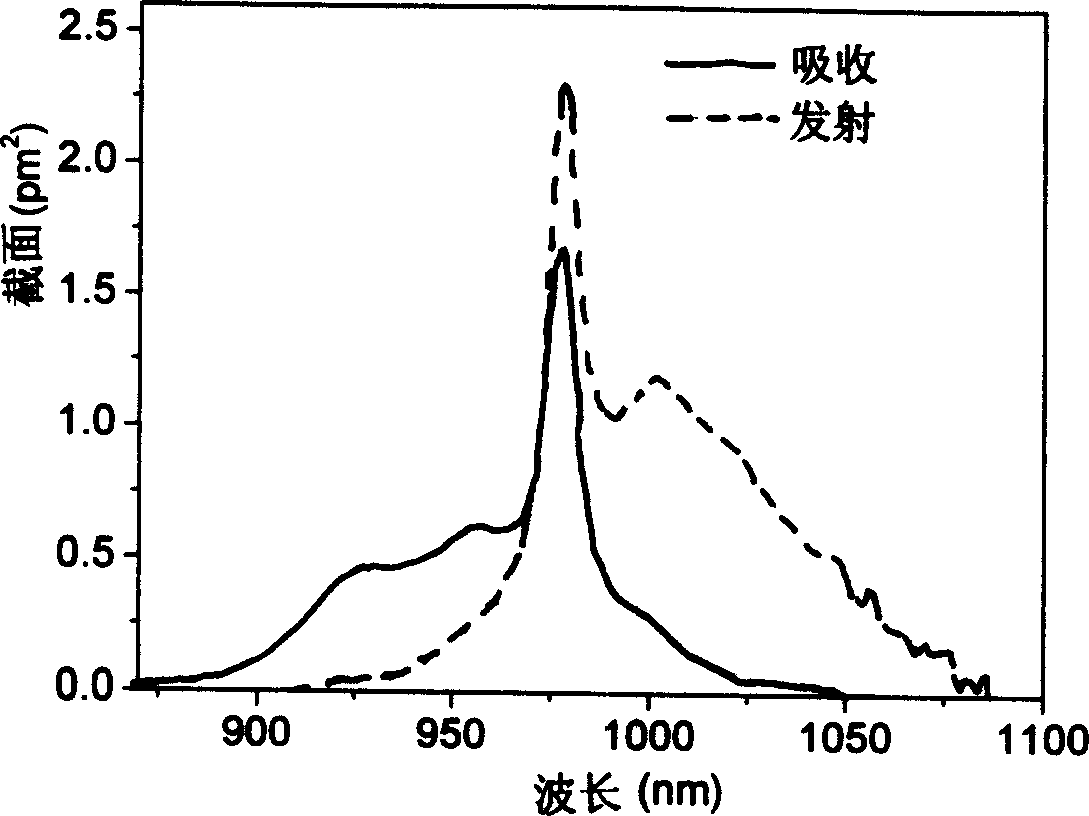

Yb3+ blended tellurate glass and its preparing method

A tellurate glass and glass technology, applied in the field of tellurate glass, can solve the problems of poor devitrification resistance, less research on doped tellurate glass, etc. Effect of Devitrification Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

[0032] The molar composition of the glass formulation of the present invention is shown in Table 1.

[0033] Table 1: Formulation composition of oxyfluoride glass-ceramics (mol%)

[0034] TeO 2

60~80

ZnO

5~15

WO 3

0~25

Na 2 o

0~5

K 2 o

0~5

La 2 o 3

0~4.5

Yb 2 o 3

0.5~5

[0035] Table 2 has listed the Yb of 7 groups of specific examples 3+ Doped tellurite glass formulations;

[0036] Table 2 The 7 groups of Yb implemented in detail 3+ Doped Tellurite Glass Formulation

[0037] glass component

No. 1

2nd

No. 3

No. 4

number 5

number 6

No. 7

TeO 2

80

75

70

70

70

65

60

ZnO

15

15

15

10

5

5

5

WO 3

0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com