High refractive index middle-expansion core material glass for middle-expansion optical fiber image inverter, and preparation method thereof

A high-refractive-index, core glass technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of the optical fiber imager not having the ability to transmit light, devitrification, and weak anti-devitrification ability, etc. Special production process requirements, good devitrification resistance and high glass transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Corresponding to the above formula system, a method for preparing a high refractive index medium expansion core material glass for a medium expansion optical fiber inverter comprises the following steps:

[0030] 1) Add raw materials into a platinum crucible at 1380-1420°C;

[0031] 2) After the feeding is completed, the temperature is raised to a clarification temperature of 1450±10°C within 30-40 minutes, and the clarification time is 6-8 hours;

[0032] 3) After clarification, it takes 30-60 minutes to cool down to the pouring temperature of 1270-1290°C, and cast into a glass rod in the mold;

[0033] 4) The molded glass rod should be annealed at 550-600°C after demolding, keep warm for 2-2.5 hours, then turn off the power to cool down, and then take it out of the oven at room temperature.

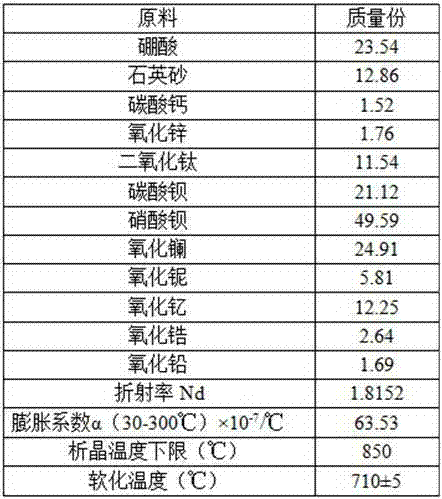

Embodiment 1

[0036] A high-refractive-index medium-expansion core material glass for a medium-expansion optical fiber inverter, which is composed of the following raw materials in parts by mass:

[0037] Table 1

[0038]

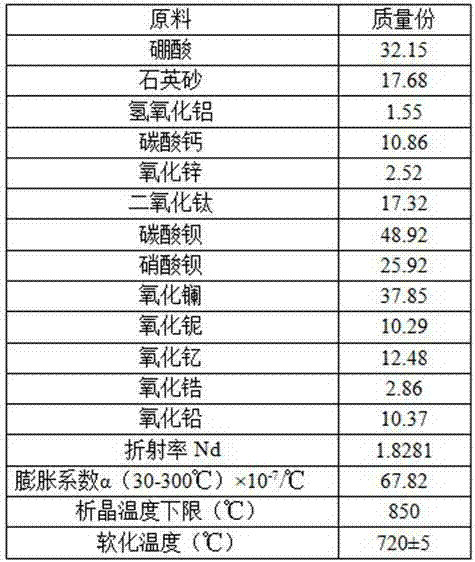

Embodiment 2

[0040] A high-refractive-index medium-expansion core material glass for a medium-expansion optical fiber inverter, which is composed of the following raw materials in parts by mass:

[0041] Table 2

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com